The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

For the Grater, Good: The Value of Informal Experiments for Understanding Bipolar Flaking and Manioc Grater Teeth

Informal experiential experimentation is often helpful for understanding a technology and raising interpretive questions and testable hypotheses. Here, a simple experiment in manufacturing microlithic flakes by bipolar percussion and using them as teeth in a wooden grater, helped us understand archaeological evidence of such teeth and the ‘manioc complex’ on San Salvador, Bahamas. A simple technology may not be unskilled, and the resulting products may appear crude yet function effectively. The lack of evidence of small stone tools may be the result of taphonomic or recovery processes, but if grater tooth manufacture was common at excavated sites, more evidence should survive.

In 2019, we began a reassessment of the lithic artifacts from excavations on San Salvador, Bahamas, mostly carried out by field schools under Mary Jane Berman and Perry Gnivecki (1995; Berman and Whittaker, 2024). These were sites occupied from late pre-contact times (ca. AD 700-800) until a bit after the landfall of Columbus on San Salvador, by people of a culture archaeologists labelled as Lucayan. The Lucayan island economy depended on coastal resources, a variety of wild plants, and agricultural products including maize and manioc. They were also notable seafarers who maintained extensive contacts with other parts of the Caribbean (Berman, 2011; Berman, Gnivecki and Pateman, 2013). The lithic artifacts recovered by modern excavations using fine-mesh (1.58 - 3.0 mm) screens in sites of the Lucayan culture are mostly tiny irregular bits of chert, many of which show features indicating that they were produced by bipolar percussion techniques (Berman, Sievert and Whyte, 1999). Although some of these flakes are usable as small tools for cutting tasks, in the Caribbean, artifacts like these are usually interpreted as teeth for manioc graters. DeBoer (1975), Lewenstein and Walker (1984) and Perry (2005) have reviewed and criticised the assumptions involved. There is some evidence for such use in the form of microwear from other sites, and the presence of starch grains and phytoliths, including some found on Berman's San Salvador flakes (Berman and Pearsall, 2008; Berman and Pearsall, 2020; Ciofalo, et al., 2018).

As we examined the artifacts, I (JW) realised that I knew too little about graters and bipolar flakes. Experimental replication is how I tend to approach artifact studies. I did not intend an extensive program or rigorously controlled experiments, and that is a point I wish to make here: that even simple experiential replicative work, based on careful reading of ethnographic sources, is a fruitful source of testable hypotheses and often critical to any basic understanding of a technology.

The 'manioc grater' (See Figure 1) is important in the minds of Latin American, South American, and Caribbean archaeologists who see it as emblematic of a distinctive tropical horticulture that relied on a simple but clever technology allowing people to exploit root crops that are difficult to document archaeologically. Graters are wooden boards studded with stone chips or other sharp bits, and used to grate manioc, producing a coarse to fine 'flour' that can be cooked on griddles, and allowing toxins present in some varieties of manioc to be pressed out. At least that is the normative view. As DeBoer (1975) and others (Perry, 2005) have pointed out, the archaeological utility of the manioc complex concept is questionable on many grounds, the most important being our limited ethnographic information on the manufacture and use of such artifacts. The ceramic griddles used to cook the manioc pulp are not readily distinguishable from similar artifacts used elsewhere to prepare maize tortillas. Many other crops besides manioc can be grated, and grating is not necessary to preparing manioc, even the sometimes toxic 'bitter' varieties. The grater boards are highly variable in size and material; many ethnographic ones are 'toothed' with organic bits like thorns, or other small and hard-to recognise teeth made of shell, fish teeth, or bone. Some even have no added teeth at all, just ridges on the board. In addition, manioc can be grated on nothing more than a rough rock (DeBoer, 1975; Kamienkowski and Arenas, 2017; Roth, 1924). These suggest many localised adaptations, and the possibility of using grater boards to produce everything from chunks and shreds to pulp, and to process all sorts of foodstuffs.

There may be evidence for stone-toothed grater boards even where the boards do not survive, in the form of phytoliths, starch grains, and other plant materials on small stone flakes that may or may not have distinctive forms or wear (Berman, Sievert and Whyte, 1999; DeBoer, 1975; Lewenstein and Walker, 1984; Perry, 2005; Walker, Wilk and Clark, 1989). We will confine ourselves to discussing stone-toothed graters, recognizing full well that they may represent only a small fraction of the possibilities for root crop preparation in the Bahamas.

To begin with, stone grater teeth are rarely recognised in archaeological deposits, especially before fine screening and flotation became common practices. Everyone agrees that they are small, sometimes minute. The small size, usually less than 10 mm, makes them difficult to examine as well as to recover. They do not seem to be very shapely or carefully crafted artifacts, although the full boards may be. The ethnographic accounts and the archaeological specimens agree that manufacture is simple, often just smashing rocks into small bits, or using slightly more systematic bipolar percussion techniques to produce small sharp flakes. Ethnography and the biases of the old dominant (i.e. male) anthropologists again converge to influence us: this kind of tool was often made and used by women, so it did not (and does not) always receive the attention it deserved.

As part of this project, I (JW) undertook some simple experiments in grater manufacture, not to produce controlled experimental replications, but through experience to think about the problems inherent in making stone-toothed graters. I had not worked much with bipolar percussion, or even with making small flakes in any systematic way, and I soon found that archaeologists probably undervalue the skill necessary to be efficient at it. One had best be efficient if the goal is to make a board with several hundred stone teeth. Again, I recognised my bias as a replicator: bipolar flaking does indeed require practice, but it produces little of the sensual and artisan pleasure to be found in making a nice bifacial projectile point.

The only grater specimen I could physically handle before attempting replication is obviously not a good sample of the range of variation, but it is compatible with descriptions in the literature (See Figures 1 and 2). It was obtained in Brazil by my friend David Campbell, a biologist working along the Amazon. It is most likely a small board that was made for sale by the Waiwai people. It is consistent with information about Waiwai graters from Yde (1965, 32-38) and Peter Siegel (personal communication 2022). The board is 55 x 21 x 2.2 cm, with a grater area 31.5 x 7.25 cm. Yde believes the Waiwai used some sort of metamorphic rock, possibly hornfels for their grater teeth. To me, the teeth appear to be a coarse slightly grainy red and black chert, laid out along a faint green painted diagonal grid in irregular rows. We estimated it had about 700-800 teeth. Individual teeth measured with a digital calliper averaged 2.30 x 4.56 mm, with 4.5-4 mm protruding above the board, so probably a similar length was embedded. Rounding is visible with a hand lens on many teeth, which might be wear, although they are still clearly smashed fragments rather than natural clasts. The black painted decoration covers the points of chips in the centre where a lizard design is painted over them and shows no sign of wear, so our guess is that the board was made for tourist sale.

Two studies informed my experiments with grater manufacture, that of Walter Roth (1924) among the Taruma, and Richard Wilk's description of Belizean Garifuna (Walker, Wilk and Clark, 1989) plus some photographs kindly provided by Wilk (personal communication 2021).

Walter Roth was very much an old-fashioned male ethnographer, but like many such, he had a wide curiosity and recorded in minute detail anything that caught his interest. I came to appreciate his work (1924) in South America, because his commentary on graters (pp. 277-280) captured unexpected bits of insight. Among the Taruma of Guiana (neighbouring and related to the Waiwai), he described the manufacture of grater boards and stone teeth for them, starting with smashing rocks and manufacture of flakes by direct percussion, then smashing the flakes and trimming selected bits into teeth with a broken 'cutlass' (i.e. machete). His account perhaps forms the basis for most archaeological attempts to experiment with graters (Lewenstein and Walker, 1984; Walker, 1980; Walker, Wilk and Clark, 1989). Significantly, it was women's work to make the teeth and both men and women inserted them into the large boards made by the men. It took three days of hard work on the part of a wife to make a board; Peter Siegel (personal communication 2022) suggests "40+ hours." The sensual experiences of ethnographic stone-working are rarely recorded, but Roth commented that "the tapping continues from morning until night, and when a large number of women are engaged at the work, the din becomes almost unbearable to an outsider." Flakes to be shaped were pinned down with the forefinger and "On account of the cutlass edge catching the upper end of the finger nail each time a blow is struck, the latter undergoes a curious horny development." These details convey several things: the intensity and frequency of this activity, and the specific 'geste' used in doing it, implying practice and skill.

As a term, "bipolar flaking" generally encompasses three somewhat different techniques. (I exclude the European usage meaning cores of any size with opposed platforms, which I consider a confusing misapplication). The most common expectation of bipolar knapping is that it involves smashing a piece of material between the blow of a hammerstone and a supporting hard 'anvil' (See Figure 3). This can be relatively uncontrolled or even unskilled, to produce small irregular sharp fragments, but when carefully done, can be used to produce small flat flakes from small pieces of raw material that would be hard to work by direct percussion in the hand. Bipolar percussion can also be taken to mean resting a small core on a hard support to keep it from moving when struck, in which case again small flat flakes can be produced. In both cases, but most especially in the first, fracture may initiate both at the point of percussion struck by the hammer, and at the contact with the hard support. Accordingly, on some of the core remnants, on the fragments, and especially on more desirable flakes, there may be bulbs of percussion or their negatives on both ends, and scar features like ripples that run both ways toward the centre of the piece. Bipolar smashing of small cores also often produces sheared or shattered rather than coned initiations, irregular sharp fragments, and sometimes deep hinge terminations on the cores. A third use of bipolar flaking is to retouch or trim a small flake supported on a hard surface. Reviews of these ideas can be found in a number of articles (e.g. Ahler, 1989; De la Peña, 2015; Pargeter and Eren, 2017; Pargeter, de la Peña and Eren, 2019; Shott and Tostevin, 2015). Hiscock (2015) favours a restrictive definition emphasising compressive forces between the hammer blow and the anvil. I rather agree, but with the caveat that even when this is the goal, not all blows will work this way, and not all of the products will show compressive features (Ahler, 1989).

Two significant interpretive assumptions are usually made about bipolar flaking. It is often considered as economising, a way of exploiting small pieces where material is scarce or valuable. I believe we see this in some obsidian usage in sites in the southwest US (Kamp and Whittaker, 1999, pp.91-92; Parry and Christenson, 1987, p.110). It is also considered to be a very low-skill technique suitable for early hominins (Gurtov, Buchannon and Eren, 2015), and the somewhat insulting assumption is made that in modern times it is thus likely to be used by women, for which there is a little ethnographic support (Sillitoe and Hardy, 2003). The wide geographic and temporal spread of bipolar techniques includes examples where economising may not be the goal, for instance splitting open large, rounded nodules (Duke and Pargeter, 2015; Hayden, 1980), or making specialised small flake tools (Flenniken, 1981). The idea that it is a low-skill technique has also been questioned (Devriendt, 2011; Duke and Pargeter 2015; Shott and Tostevin, 2015).

We consider Roth a fairly reliable observer, even though like most anthropologists at the time he probably had little practical experience with knapping. I think we can use his description of Taruma knapping, and that of Wilk's Garifuna in Belize (Walker, Wilk and Clark, 1989) as reasonable guides to common practices in producing grater teeth. The Taruma women obtained stone from a quarry and broke the larger pieces of rock one on another. "Flaking is now commenced in the usual manner along any convenient ridge…" I take this to mean by direct unsupported percussion. According to Roth (1924, pp.277-280), the Taruma women produced small flakes skilfully, discarding only 5%, careless of size or shape except keeping the thickness uniformly around 1/16 inch (1.58 mm). At that point, the work proceeds by what we can call bipolar flaking, with the flake supported on the board. "[The woman] will, with a sharp blow at the centre, smash the flake into a varying number of pieces. Of these latter only a few will be suitable for her purpose, and of these few one or perhaps two may be of the necessary shape ready to be driven into the board straight away, while others may require narrowing or pointing. To do this she securely presses the chip under her left forefinger nail, covering with it all that portion which she wishes to retain, and leaving exposed that which is not required. The latter she then pulverises with a blow of her cutlass." Roth says the desired final teeth should be pyramidal with two broad faces that will be parallel to the long axis of the board when inserted. A rather poor photo shows jagged small pieces that appear to be roughly triangular ('pyramidal') in cross section, but flake details are invisible.

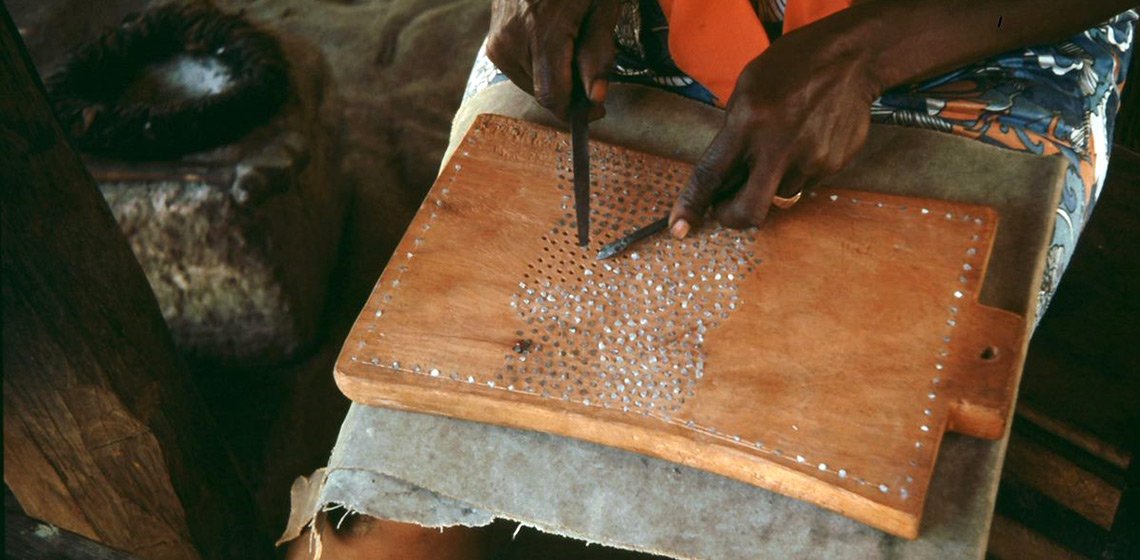

If we parse Roth's account a bit, we see again that making grater teeth involves a good deal of skill, even if the final product is small and crude looking. In this case also, smashing the parent flakes on a wooden board might not be expected to yield typical bipolar traits on the fragments, but one could as easily do this on a hard anvil, in which case it might, although in my experience, smashing a flat flake more generally produces narrow sherds without many flake features. Likewise, the retouch should not look particularly 'bipolar' on either the tooth or the tiny waste flakes. It is, of course, possible to produce the parent flakes by bipolar percussion, or to make small bipolar flakes to trim up as teeth instead of smashing larger ones. This is indeed what Wilk (Walker, Wilk and Clark, 1989) reports from observations in 1980 among the Garifuna in Belize. Quartzite nodules were smashed with a hammer on the ground, and the resulting fragments were smashed with the hammer on a concrete anvil with a depression and a fabric ring to confine the fragments (See Figure 4). The results were sieved, and pieces selected that were rounded but with one sharp end, retouched if necessary, by bipolar percussion with a file on a stone anvil held in the lap (See Figure 5). This manufacturing process might well leave bipolar traits on some of the teeth. However, the bipolar traits that have been observed on some grater teeth, including ours, may come as much from hammering them into the boards as from making them.

For archaeological considerations, a significant aspect of Roth's account, which I have found true in my experiments with bipolar flaking, is that a large percentage of the pieces produced are too small or too irregular to be used, or too small and thick to be shaped. Although bipolar flaking is conceived as conservation of material, it is only so in the sense of using small pieces that are difficult to work otherwise. If you make hundreds of grater teeth, you will produce thousands of bits of debitage. When we consider the issue of waste, and how little was found even by careful modern excavation with fine mesh sieving on San Salvador, we have to wonder if much knapping was done there, or if the bits of stone represent the occasional import of graters rather than flint.

And finally, we get to inserting the teeth in the board, and using them, both likely to affect their final appearance as found archaeologically. The ethnographic accounts tell us that you should make holes in the wooden board to receive the teeth (Roth's Taruma used a deer-bone tool), but no one says anything about the hole size. They need to be small enough to be tight, and large enough to insert the teeth. You can't just hammer stone teeth into wood like a nail; they are fragile. Furthermore, I discovered that even my fingers, which are not very large, have a hard time manipulating little flakes. Think about hammering very short nails with a clumsy hammer. The account of ethnographic grater making in Belise by Richard Wilk (Walker, Wilk and Clark, 1989) provided more guidance than Roth. Unless you are trying to replicate a process, you miss details. Wilk's Garifuna informant made the holes in her board with a hammer and nail, as did Siegel's Waiwai informants. The teeth were driven in by indirect percussion with a nail, and photographs provided by Wilk (personal communication 2021) show this being done with the nail laid on its side across the flake, rather than using the end like a punch (See Figure 6). This proved to be the only way I could do it, making a hole larger and deeper than the tooth (I used a screwdriver), and driving the teeth into it with the screwdriver laid across them (See Figure 7). This provided a much larger target, reduced damage to my fingers, and resulted sometimes in crushing and flaking the top of the tooth. This dulling effect probably does not matter and is unavoidable. Walker, Wilk and Clark (1989) note that the desired teeth may be knapped sharp on one end to drive into the wood, but the dull end will be left projecting.

The grater board I made was quite small (See Figure 8). The toothed area was about 8x14 cm and incorporated about 70 teeth, made from whatever I had on hand: some quartzite from Wyoming, cherts from the Little Colorado River gravels and elsewhere in Arizona. The quartzite proved a bit more fragile when driving bits into the board. My teeth were larger than those in my ethnographic specimen, but within the range of the microliths from San Salvador and grater teeth in the literature. They varied from 0.4 - 1.4 mm wide, and but were consistently around 3 mm thick. I inserted them to protrude 4-5 mm from the board. In other words, this was a rather coarse grater, largely through my inexperience. Following the account of Roth and others that the teeth were often stabilised in a grater board by pouring some thin mastic over it, I used shellac. My self-criticism of the board was that the teeth were too flake-based and driven into slots rather than narrower sherds driven into holes, which is how I read most of the descriptions. My small grater cost me a lot of time and effort, and I had to discard a high percentage of the chert materials I used. I gained a lot of respect for anyone who could efficiently produce a large grater. No wonder perforated sheet metal has replaced stone-toothed graters in most areas.

I tried grating a large baking potato on my board (See Figure 9). A potato is not a manioc, so again, this is a limited test, but the board was vastly more effective than I expected and took less effort. Although I felt the teeth were widely spaced and would cut the potato into chunks, it shredded it quickly into what looked exactly like hash browns. We squeezed out about 1/3 cup of liquid from the shreds, which left about a quarter inch of gooey starch at the bottom of the cup when it settled (See Figure 10). I had to leave a good stub of potato ungrated, as the prospect of accidentally running my fingertips through the flakes frankly scared me. When finished, I had lost no teeth from the board (See Figure 11).

Lessons learned and summaries

Much of the point of this account is to show how much we learn from unsystematic, uncontrolled, experiential experiments. All these words have been used sneeringly by those who feel that the only truly useful science comes from artificial experiments where variables are tightly controlled and systematically varied, or replications that conform elaborately to archaeological evidence. Most serious experimenters, however, recognise that experiments at many levels of control and detail are useful and necessary, wherever their own work falls on these scales.

In this case, we learned several things useful for interpreting the San Salvador lithic assemblages and suggesting hypotheses that could be tested:

- Bipolar flaking was the usual mode of production. We would like to interpret this as a regional tradition, in which the technique was impelled by scarcity of raw material, as there are no siliceous stones on San Salvador. This in turn would have inhibited the development of more complex lithic artifacts. This does not, however, imply that flake manufacture was unskilled, or necessarily unspecialised. The scarcity of imported materials may have meant that few people had the skill to work them, or that the material itself was a valued good controlled by certain people. Understanding this situation requires comparable data from much more excavation on other sites.

- Although the sparse evidence of residues on some flakes supports the usual interpretation that they were elements of graters for food processing, we should look beyond the 'manioc complex.' In the first place, some quite small flakes, 'microliths', can be hafted and used for a variety of tasks. For instance, Flenniken's evidence for fish processing with hafted quartzite bipolar flakes on the Northwest coast of North America seems particularly relevant (Flenniken, 1981).

- Also looking beyond the manioc complex, we must recognise the problems with the concept, mentioned earlier. In particular, for our San Salvadoran material, the limited residue evidence suggests grating or otherwise processing a variety of different crops and wild plant foods. We unfortunately have no good use-wear evidence, although we think we see wear on some of the stones. Here, both archaeological and experimental information will be necessary. There are practical barriers to performing extensive controlled experiments to produce comparative residue and use-wear data. Making a suite of grater boards would be onerous and time-consuming, especially if one intended to examine the before and after conditions of the flakes, and increasingly so as experiments attempted to test different raw materials, processed plant materials, and other aspects. Since graters do not require stone teeth, it would also be good to try other materials.

- The relative scarcity of silicious stone teeth on San Salvador must mean something. The sites excavated by Berman and Gnivecki were carefully excavated and fine-screened. If there had been extensive manufacture of chert artifacts, we should see more debris, and if chert-toothed graters were in common use, far more of the teeth. It is possible that at least some of the chert bits arrived on the island already inserted in grater boards. It seems likely that other materials were used on the island, especially shell and limestone, both of which are difficult to recognise as artifacts in the sites.

Acknowledgements

We thank Richard Wilk and Peter Siegel for sharing personal observations and photographs; we are grateful for permission to use some of Richard Wilk’s.

Keywords

Country

- the Bahamas

Bibliography

Ahler, S.A., 1989. Experimental knapping with KRF and midcontinental cherts: overview and applications., In D.S. Amick and R.P. Mauldin, eds. Experiments in Lithic Technology. Oxford: BAR International Series, 528, pp.199-234.

Berman, M.J., 2011. Good as gold: the aesthetic brilliance of the Lucayans. In A. Curet and M.W. Hauser, eds. Islands at the Crossroads: Migration, Seafaring, and Interaction in the Caribbean. Tuscaloosa: University of Alabama Press, pp.104-134.

Berman, M.J. and Gnivecki, P.L., 1995. The colonisation of the Bahama Archipelago. World Archaeology, 26, pp.421-441.

Berman, M.J., Sievert, A.K. and Whyte, T.R., 1999. Form and function of bipolar lithic artifacts from the Three Dog Site, San Salvador, Bahamas. Latin American Antiquity, 10(4), pp.415-432.

Berman, M.J. and Pearsall, D.M., 2008. At the crossroads: starch grain and phytolith analyses in Lucayan prehistory. Latin American Antiquity, 19(2), pp.181-203.

Berman, M.J., Gnivecki, P.L. and Pateman, M.P., 2013. The Bahama archipelago. In W.F. Keegan, C.L. Hofman and R. Rodríguez Ramos, eds. The Oxford Handbook of Caribbean Archaeology. Oxford: Oxford University Press, pp.264-280.

Berman, M.J. and Pearsall, D.M., 2020. Crop dispersal and Lucayan tool use: investigating the creation of transported landscapes in the central Bahamas through starch grain, phytolith, macrobotanical, and artifact studies. Journal of Field Archaeology, 45(5), pp.355-371. https://doi.org/10.1080/00934690.2020.1740958

Berman, M.J. and Whittaker, J.C., 2024. Investigating morphological and functional variability and frequency in Lucayan bipolar microliths from the central Bahamas. Journal of Archaeological Science: Reports, 57, 104469.

Ciofalo, A.J., Keegan, W.F., Pateman, M.P., Pagán-Jiménez, J.R. and Hofman, C.L., 2018. Determining precolonial botanical foodways: starch recovery and analysis, Long Island, The Bahamas. Journal of Archaeological Science: Reports, 21, pp.305-317.

DeBoer, W.R., 1975. The archaeological evidence for manioc cultivation: a cautionary note. American Antiquity, 40(4), pp.419-433.

De la Peña, P., 2015. A qualitative guide to recognize bipolar knapping for flint and quartz. Lithic Technology, 40(4), pp.316-331.

Duke, H. and Pargeter, J., 2015. Weaving simple solutions to complex problems: an experimental study of skill in bipolar cobble-splitting. Lithic Technology, 40(4), pp.349-365.

Flenniken, J.J. , 1981. Replicative systems analysis: a model applied to the vein quartz artifacts from the Hoko River Site. Washington State University Laboratory of Anthropology Reports of Investigations No. 59, Pullman: Washington State University.

Gurtov, A.N., Buchannan, B. and Eren, M.I., 2015. "Dissecting" quartzite and basalt bipolar flake shape: a morphometric comparison of experimental replications from Olduvai Gorge, Tanzania. Lithic Technology, 40(4), pp.332-341.

Hayden, B., 1980. Confusion in the bipolar world: bashed pebbles and splintered pieces. Lithic Technology, 9(1), pp.2-7. https://doi.org/10.1080/01977261.1980.11754456

Hiscock, P., 2015. Dynamics of knapping with bipolar techniques: modeling transitions and the implications of variability. Lithic Technology, 40(4), pp.342-348.

Kamp, K.A. and Whittaker, J.C., 1999. Surviving Adversity: The Sinagua of Lizard Man Village. University of Utah Anthropological Papers Number 120. University of Utah Press, Salt Lake City.

Lewenstein, S.M. and Walker, J., 1984. The obsidian chip/manioc grating hypothesis and the Mesoamerican Preclassic. Journal of New World Archaeology, 6(2), pp.25-38.

Pargeter, J., de la Peña, P. and Eren, M., 2019. Assessing raw material's role in bipolar and freehand miniaturized flake shape, technological structure, and fragmentation rates. Archaeological and Anthropological Sciences 11:5893-5907.https://doi.org/10.1007/s12520-018-0647-1

Pargeter, J. and Eren, M.I., 2017. Quantifying and comparing bipolar versus freehand flake morphologies, production currencies, and reduction energetics during lithic miniaturization. Lithic Technology, 42(2-3), pp.90-108. https://doi.org/10.1080/01977261.2017.1345442

Parry, W.J. and Christenson, A.L., 1987. Prehistoric Stone Technology on Northern Black Mesa, Arizona. Center for Archaeological Investigations Occasional Paper 12, Southern Illinois University, Carbondale.

Perry, L., 2005. Reassessing the Traditional Interpretation of "Manioc" Artifacts in the Orinoco Valley of Venezuela. Latin American Antiquity, 16(4), pp.409-426.

Roth, W.E., 1924. An introductory study of the arts, crafts, and customs of the Guiana Indians. Thirty-eighth annual report of the Bureau of American Ethnology, 1916-1917. Washington D. C.: Bureau of American Ethnology, pp.25-720.

Shott, M. and Tostevin, G., 2015. Diversity under the bipolar umbrella. Lithic Technology, 40(4), pp.377-384.

Sillitoe, P. and Hardy, K., 2003. Living lithics: ethnoarchaeology in highland Papua New Guinea. Antiquity, 77(297), pp.555-566.

Walker, J.B., 1980. Analysis and replication of the lithic artifacts from the Sugar Factory Pier Site, St. Kitts, West Indies. MA thesis. Washington State University.

Walker, J., Wilk, R. and Clark , J.E., 1989. Manufacture and use-wear characteristics of ethnographic, replicated, and archaeological manioc grater board teeth. In M.G. Gaxiola and J.E. Clark, eds. La Obsidiana en Mesoamerica. Mexico D.F.: Instituto Nacional de Antropologia e Historia, pp.459-463.

Yde, J., 1965. Material Culture of the Wai Wai. Copenhagen: Nationalmuseets Skrifter Ethnografisk Rǿkke, The National Museum of Copenhagen. Available at: <https://www.scribd.com/document/468473809/Material-Cuture-of-the-Waiwai-Jean-Yde [Accessed 08 August 2024]