The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

Is it Possible to Weave 8.end Satin with 5 Rods on a Warp-weighted Loom?

Back in 2020, I wrote an article entitled The Shroud of Turin and the Extra Sheds of Warping Threads (Olsen, 2020). When I was studying the weaving theory, I realised that it might be possible to weave 8-end satin with five rods on the warp-weighted loom. To date, I have not encountered any historical find showing satin woven on a warp-weighted loom eighter, nor have I heard or read about anybody else undertaking this, so I decided to try to test it.

Introduction

Satin is the third group of basic weaves (Zetterström, 1983, p. 33) and comprises two types: warp-faced satin and filling-face satin. A warp-faced satin fabric has long floats in the warp direction and a filling-face satin fabric has long floats in the filling direction. The arrangement of the interlacing points is determined by a counter, which is a set number that dictates how far from the previous interlacing point, the next one will be positioned.

It is also possible to weave an 8-end satin. The only possible counters for a 5-end satin are two and three. For the 8-end satin the possible counters are three and five (Svarstad, 1998, p. 25). Will it be possible to do the same on a warp-weighted loom?

In preparation I drew different types of patterns using the guidelines for how to make a 5-end regular satin pattern (Zetterström, 1983, p. 34) (See Figures B, D, E, F, G, H, I, J and K). Back in 2020, when I put up the 3/1 chevron twill, I got extra warping threads in an extra shed. Since the 3/1 chevron twill and the 5-end satin patterns are quite similar, I believed I would get extra warping threads this time too. Therefore, I decided to go for an 8-end regular satin with a counter of three, even if I could only use five rods, since there was no space for more than five rods on my warp-weighted loom (See Figure 7).

Methodology

When I wanted to try to put up a satin with four rods and the shed rod (five rods in total), I decided to use the same kind of wool yarn as when I put up the test weave for 3/1 chevron twill (See Olsen, 2020). I also used a rigid heddle and a warping frame. For weft yarn I used wool and linen. There are two ways to make a starting border, that I know of, and I refer to both below.

The starting border

I used 14/2 worsted yarn for the warp and the weft of the starting border. There are 12 threads in the starting border. As usual, I used a rigid heddle when I was making the starting border, and also used a warping frame (See Figure A) and (Olsen, 2014, pp. 58 - 62).

The warp for my first test weave

- I started with weaving 9 cm of the starting border (See Figure A) and (Olsen, 2014, pp. 58 - 62). Then I began to make the warping for my test weave, using the same procedure as when I made the warping for the 3/1 chevron twill (Olsen, 2020).

- The warping frame is laying on a table approximately 1.5 meters away from the starting border (See Figure A).

- I made the warping threads by taking the first loop formed by the weft of the starting border, carried it over to the left peg, and dropped the loop down onto the peg (See Figure A).

- I went back to the starting border and made a new shed in the starting border, by using the rigid heddle. Then I did the same again, as described in point 3.

- I made four loops and dropped them down onto the right peg. I then dropped a new loop down onto the left peg before I made four new loops onto the right peg.

- In total, I made 10 double loops onto the left peg and 40 double loops onto the right peg (See Table 1).

- Then I wove the last 9 cm of the starting border.

- I chained down the warp and stitched the starting border onto the beam on my warp-weighted loom (Olsen, 2014, pp. 64-67).

- I tied the warping threads to the weights (Olsen, 2014, pp. 68 - 71) and crocheted one spacing cord for the warping threads in the back row of the shed rod, and one spacing cord for the warping threads in front of the shed rod. (Olsen, 2014, pp. 72- 73).

| Distribution of warping threads | ||

| Double warping threads | Single threads | |

| Back threads | 10 | 20 |

| Front threads | 40 | 80 |

Table 1. Distribution of warping threads for 5 end satin on the warp-weighted loom.

Threading the warp onto the heddle rods

I then came to the most difficult part of my weaving test. How would I be able to thread a satin weave, and use five rods on the warp-weighted loom? Neither Hansen (1978) nor Hoffmann (1964) mentioned any satin weaving in their books.

- After threading the shed rod (putting the front threads in the front of the shed rod and the back threads in behind of the shed rod), (Olsen, 2014, p. 69), I started to thread heddle rod number 2, for two reasons; 1) I always thread heddle rod number 2 after the shed rod (Olsen, 2014, p. 81). Normally, they are threaded opposite of each other. Since they, this time, are not threaded opposite of each other, I had to use single thread number 2 of each of the double warping threads hanging from the back of the shed rod (See Figure 3).

- When I had completed heddle rod number 2 I threaded heddle rod number 3. Since heddle rod number 3 is normally threaded opposite heddle rod number 1 (Olsen, 2014, p. 81), and heddle rod number 3 is normally the last heddle rod to be threaded and heddled, I was very eager to see how this would work out.

- To be able to pick heddle rod number 3 I had to use the first single thread from each double warping thread hanging behind the shed rod (See Figure C).

- Then I could thread heddle rod number 1, using the one thread of each double warping thread threaded on heddle rod number3. Then, I could thread heddle rod number 4, using the second thread of each double warping thread on heddle rod number 2 (See Figure C).

- X1, X2 and X3 were extra threads that I could not get threaded on rods as there was no space on my loom. As a result, each time I used them in a pattern, I had to hand pick them with a needle before I could weave (See Figure C).

- The extra warping threads were not threaded but heddled.

- For every heddle rod I threaded, I heddled each rod before I moved on to threading the next rod. (Olsen, 2014, pp. 96 -105).

The weaving process

- I wove the satin the same way as I normally do on the warp-weighted loom (Olsen, 2014, pp. 88 -89).

- To weave an 8-end regular satin, I had to hand pick the three "extra" rods since I had no space for eight rods on my warp-weighted loom. I used a needle when I was picking up the three extra rods (See Figure 8).

- I followed the patterns I had designed for the satin weaving for the warp-weighted loom (See Figures C, F, G, 2, 3 and 8).

- After the first test weave, I put up another 8-end test weave. This time, I wove another pattern I had designed myself since there are not many satin patterns fitted for the warp-weighted loom that I know of (See Figures 7, 8, 9, E, F, G, H, I, J and K).

- As weft I used both wool yarn and linen yarn

Result

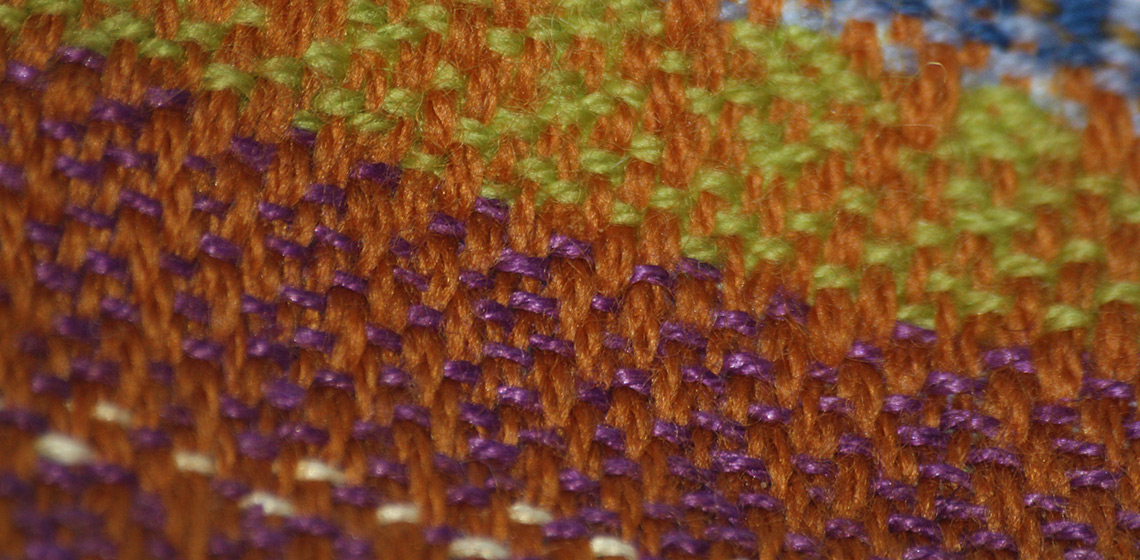

I was surprised and thrilled to see and experience that it was possible to weave 8-end satin with five rods on the warp-weighted loom. It did not require more time to weave a satin, compared to the amount of time it would take to weave a 2/2 twill or a 3/1 chevron twill. Both test weaves produced in this study, were warp-faced satin, with faced back sides (See Figures 1,2, 3, 4, 5, 6, 7, 8, and 9).

Discussion

When I put up the 3/1 chevron twill, I noticed that a 5-end satin was very similar to the 3/1 chevron twill (See Figure B). Both have the shed rod and heddle rod number 3 threaded opposite each other. Another similarity is that heddle rod number 1 and heddle rod number 2 are threaded opposite each other (See figure B).

In a normal 2/2 twill on the warp-weighted loom, the shed rod and heddle rod number 2 are threaded opposite each other, and heddle rod number 1 and heddle rod number 3 are threaded opposite each other (Hansen, 1978, p. 48; Figure 54) (See Figure B).

On a 2/2 twill the rod order is, from the bottom and up 0,1,2,3 (Olsen, 2014, p. 81). In order to put up the warp and be able to weave a 5-end basic satin, the rod order must be 0,2,3,1,4. I was not able to thread the rods differently, however, I could switch the order of the rods when I wove the different kinds of patterns (See figure E, F, G, H, I, J and K).

The extra warping threads came from the starting border as single threads numbers 5, 6, 7, 8, 15, 16, 17, 18 25, 26, 27,28, 35, 36, 37, 38. Single thread numbers 5, 6, 15, 16, 25, 26, 35 and 36 were named as X1. Single thread numbers 7,8, 17, 18, 27, 28, 37, 38 were named as X2. To get an 8-end satin I used single thread numbers6, 7, 16, 17, 26, 27, 36 and 37 and named this as X3. (See Figure C).

To get the different kinds of patterns, I arranged the interlacing points determined by the counter for 5-end satin, which is either number2 or number 3. For an 8-end satin I used the counter number 3. When I was counting the interlacing point for the 8-end satin, I counted the threads as double threads, and not as single threads as is normally done (See Figure D).

In many ways it seems like the 8-point satin is a reinforced satin (Svarstad, 1998, pp. 40 - 42). If I had enough space for seven rods on my warp-weighted loom, I am sure the patterns would have looked a little bit better than they do today (See Figure E, F, G, H, I, J and K).

On my second test weave, I used the same procedure, and I counted out the interlacing point as I did in my first test weave (See Figure D). While I have drawn all the patterns myself I have not woven all of them (See Figure E, F, G, H, I, J and K).

Conclusion

The test weavings showed that it is possible to weave 5-end plan satin and 8-end reinforced warp-faced satin with long floats in the warp direction. Both the test weaves have a filling-face satin structure on the back side of the fabrics (See Figures 4, 5, and 9). The reason why I call an 8-end satin a reinforced satin is that I weave with double threads instead of using only single threads. Each interlace point in the weave becomes a double interlace point, which will make the weave stronger (See Figures C and D).

Another important point is that if I had enough space on my warp-weighted loom to put up extra heddle rods, both my test weaves would have been 7-point satin (See Figure 7). The reason for that is that there are seven pairs of double warping threads in the setup, and therefore seven interlacing numbers in my pattern, which is 0, 2, 3, 1, 4, X1 and X2. X3 is not a pair of double warping threads, since it is half of X1 (the second single thread in the pair of double warping threads for X1) and half of X2 (the first single thread in the pair of double warping threads for X2) (See Figure C). If I understand the secrets of the warp-weighted loom correctly, I could not weave an 8-point satin with seven rods. If I had set up seven rods on my warp-weighted loom, it would not have been possible to handpick X3, since X1 and X2 would have been connected to two separate heddle rods. X3 is there for a bonus interlacing, as I see it. The interlacing numbers for a 7-point satin are 2, 3, and 4 (Zetterström, 1983, p.34). However, it is possible to weave 8-end satin with five rods on a warp-weighted loom (See Figure 7).

Acknowledgements

The pattern "Twins" is named in the memory of my twin brother Tore Johan Blikeng.

I want to thank Morten Kutschera for his moral support during this experiment and writing process.

I also want to thank Rune Aasen for helping me shoot high quality pictures for this article, also for advising me when I had to take some pictures for this article.

Thank you, Pam Baker Howard, for supporting me when I was wondering if I could give names to my weaving patterns or not.

Country

- Norway

Bibliography

Hansen, E.H., 1978. Opstadvæv. Før og Nu. København: Teacos Forlag.

Hoffman, M.,1974. The Warp-weighted Loom. Studies in the History and Technology of an Ancient Implement. Oslo: Universitetsforlaget.

Olsen, A.M., 2020. The Shroud of Turin and the Extra Sheds of Warping Threads. EXARC Journal 2020/4. https://exarc.net/ark:/88735/10539

Olsen, A.M., 2014. Twill and tabby weaving on the warp-weighted loom. Asker: Den hendige hedningen.

Svarstad, F., 1998. Bindingslære og vevanalyse. Vollen: Amfora AS.

Zetterström, U.C.,1983. Håndbok i veving. Bindingslære - prydtekstiler. Stockholm: Landbruksforlaget.