The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

An Experiment with the Warp-weighted Loom and Heavy Loom Weights. The Case of the Giant Refractory Ceramic “Doughnuts” from North Piedmont, Italy

Heavy, doughnut-shaped, loom weights made of refractory clay are often found in excavations of Roman and Late Roman settlements in North Piedmont. Unfortunately, they are not found in situ with a weaving loom. We have interpreted them as having been specifically designed for use on a warp weighted loom with a lower mobile beam which is weighed down by a few heavy loom weights. This weaving loom might have been a local model which appeared before the Medieval double beam weaving loom. Our experiment consists of reproducing the weaving loom and weaving a simple tabby weave made from wool commonly used in the area during the Roman Period.

Introductions

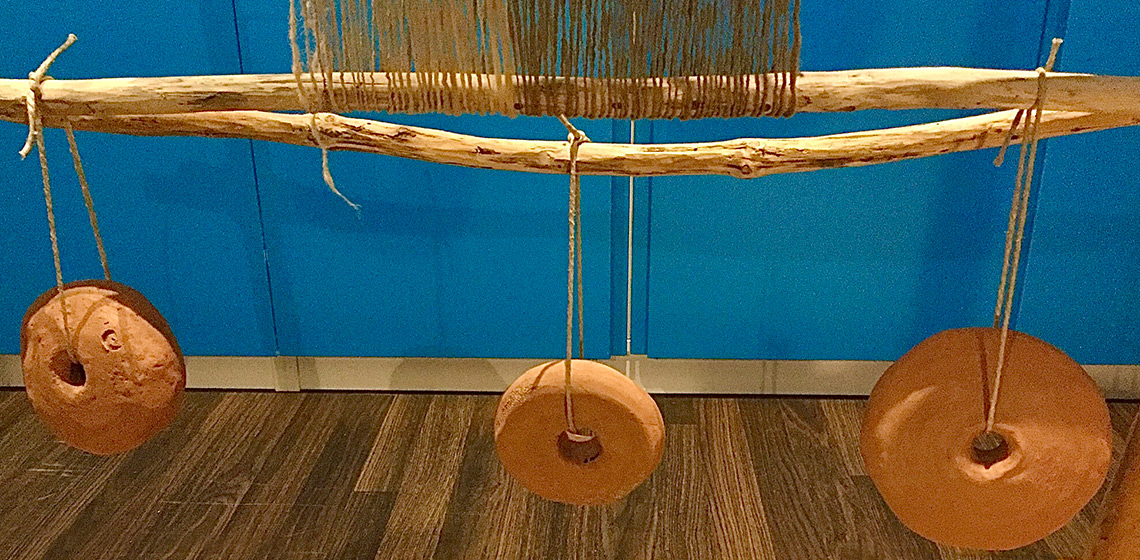

The giant, heavy, loom weights (See Figure 1) which form the focus of this study were found in 2013 during the excavation of a Roman farmstead site of the Imperial Era (excavation by Soprintendenza Archeologia Belle Arti e Paesaggio per le Province di Biella Novara Verbano Cusio Ossola e Vercelli, Italy). The settlement is situated in Fara Novarese, north of Piedmont (Italy). Coincidently, an inscription associated with a textile merchant was found in the same town and was recently restored. Although the archeological settlement is still under study and data is being processed, the material has been partially documented. Information has not yet been released on the logistics of the discovery of the loom weights, but we do know that they all originate from unit 126. Unfortunately, these layers of the Roman site were abandoned, destroyed and later covered over and used for agricultural activity. Nonetheless, remains of courtyards, rooms and spaces, a porch with pillars and cobblestone floors, as well as brick fragments were all discovered. Ongoing studies on the artifacts suggest that the settlement site was occupied between the second to fourth centuries AD. The settlement is situated near an Imperial Era burial site, which was constructed over the remains of a road, as is evidenced by remains of chariot wheel marks. Surveys undertaken prior to the excavation of the settlement indicate a late Iron Age/1st century BCE terminus post quem (Spagnolo Garzoli and Gabutti, 2015; Spagnolo Garzoli and Gambari, 2004). Other ceramic pieces, including fragments recognized as loom weights owing to their shape, color, material and weight, were found at the site. This study will however solely focus on the undamaged loom weights which belong with certainty to one layer, stratigraphic unit 126, of which there are no other stratigraphic details.

The heavy doughnut-shaped loom weights, made from refractory ceramic, are found exclusively in north Piedmont and in the northern parts of the nearby region of Lombardy. The loom weights originate from Roman settlements and can be recognized by a doughnut-shape with rounded borders and a central hole. The shape is also occasionally slightly biconical. The most important characteristics are the objects’ weight which revolves around 1500 g, and their refractory ceramic, similar in both color and composition to the bricks produced in the Roman furnaces. The loom weights have been recovered either whole or in fragments, sometimes as part of a set of multiple types containing at most five or six pieces, or sometimes singly. In this area of Piedmont, no other type of loom weight dating from the Roman period has been found and consequently these giant loom weights with diameters over 150mm are the only evidence for weaving activity (Garanzini, 2015).

Loom Weights in Piedmont

The warp-weighted loom and doughnut-shaped clay loom weights already existed from the Pre-Roman age in Piedmont. The loom weights were commonly doughnut-shaped but were much smaller than giant type studied here, and were made mostly of raw, not refined clay. Loom weights of an uneven conical shape are also found made partially from refined clay. However, pyramid loom weights from the Roman age are completely absent from Northern Piedmont, even though they are prevalent in every other Roman settlement in Italy, from the North to the South, from Aquileia to Sicily, and even beyond the Alps. They are of regular, standard shapes and are engraved and decorated. Pyramid loom weights are interesting and fascinating for their engravings and imprinted motifs, often referable to the commercial, the textile production and trade relation because they point to the commercial, production, workshop and trade relations maintained between specific productions of fabrics and patterns (Antolini and Marengo 2012, pp.149–168). Numerous sets of pyramid loom weights can be found throughout the Italian territory, with extensive case studies (Bergamini, 2009; Valentino 1997; Gleba, 2012; Basso, Busana and Bonato, 2016; for a recent case of a Roman warp-weighted loom from Piedmont see Quercia, 2019). In North Piedmont, only a few specimens of doughnut-shaped clay loom weights from the Roman period have been preserved, and they are often in a fragmentary condition because of the soil acidity levels and no loom weights are preserved in complete sets. In fact, only heavy doughnut-shaped loom weights were discovered within settlements. With no other indication of weaving practices in the area, it is reasonable to assume that objects of this shape, material and weight served no other purpose other than to weigh down a warp-weighted loom. While other similar specimens found in Veneto that date from the Bronze Age were interpreted as support bases (Panella, 1998, pp.371–376), this cannot be applied to the present case study. With a thickness of 6 cm and a central hole of a 3 cm diameter, the Fara Novarese specimens would not work as support bases. Moreover, it cannot be unexplained why support bases made from refractory ceramic, of a specific shape and consistent weight, would be used as opposed to stone bases to support the amphorae and pottery wheel (Garanzini, 2015, p.678). Therefore, in excluding the hypothesis of use as support bases, the artifacts are interpreted as heavy loom weights.

There is evidence for textile activity in the region prior to the Roman period (Garanzini, 2015, p.678). The region is indeed noted for its sheep as well as traces of transhumance. No sheep remains are preserved due to the soil acidity. However, sheep breeds from Gaul and Pollentia (Pollenzo, Cuneo), and nigra wool sheep, have all been recognized in north-western Italy. It is known that mixed breeds also existed in order to obtain higher quality wool. Analyses of wool fibers revealed that multiple types of wool were progressively used. Longer fibers, and occasionally raw but more uniform wool, were used to obtain finer yarn. This data reflects the manufacturing of different types of garments and the intensive selective breeding of sheep (Columella, 1941, 7.2; Rottoli, 2005; Bonetto, 2012; Gleba, 2012). The Lanarii, Pectinarii (carders and other wool processing) and Quactiliarii (felt makers) guilds were known during the Roman period in the Transpadana and Cisalpina areas.Fullonicae, places where fulling was done, also existed. The names of workers for the various stages of production are also recorded. Many of the names of the wool garments produced are known, such as pilei (felted hats), impilia (felted shoes) and the palla gallica or Caracalla (the long, amaranth coat) (Martuscelli, 2003, pp.27–44). Here, it is worth mentioning the discovery of a Roman inscription, found in the territory of the church of Fara, which mentions a negotiator vestiarius cisalpinus et transalpinus, in other words a merchant who traded goods across long distances in the Alps (civitas Helvetiorum, Aventicum, Switzerland). This merchant presumably traded local textile products, amongst which were most certainly wool products. The inscription has been restored and is currently under study by Mennella (2000; 2003). Evidence points to the existence of wool and textile product guilds, and to the clustering of wool production and wool merchants in Northern Italy, particularly in Altino, Milan, and Modena (Mutina). In the Gallia Cisalpina, medium to low quality wool products, alongside unfinished pieces such as the yarn, dominated the market throughout the Imperial Age up until the fourth century AD. In Northern Italy, the ‘Lanarii’ and the ‘Negotiatores Sagarii’ (from Saga, military wool cape) were the most recurring wool guilds, whereas Milan was the largest ‘emporium’ closest to the Fara Novarese area. Such guilds were composed of a blend of artisans and merchants, wholesalers and smaller producers. These groups all faced business risks and therefore chose to unite in the spirit of cooperation and commercial competition (Liu, 2012, pp.131–134; Larsson Lovén, 2012, pp.116). In fact, the presence of a vendor from the Vestiarii guild in Fara Novarese is significant because it highlights the importance of trade and local wool production under various forms. In support of an existing textile economy focused on wool, there is a complete lack of evidence, inscription or iconography, regarding the processing of plant fibers, rare are the traces of mineralized fabrics and no fragments of fabrics were preserved due to the corrosive soil. No analyses of the pollens in the area have been conducted to determine the presence of flax or hemp cultivation during the Roman era. Despite the limited data, it is presumed that throughout the entire Piedmont area, sheep breeding and production of average quality yarn and wool fabrics took place. At certain sites, the wool production was perhaps organized however no conclusions can be reached owing the limited information available. It is more correct to discuss domestic production, or production closely related to a small rural economy, in small independent family craftsmanship units where a production surplus of wool and fabrics was possibly traded across the Alps (Busana, Cottica and Basso, 2012, pp.421-425; Gostenčnik, 2012; 2014).

Generally, studies give more importance to the warp-weighted loom and the loom weights together, than to the loom weights’ different shapes and to the connections existing between local morphologies and the type of fibers woven. The lack of the study of weights’ different shapes is due to the fact that the loom weights’ sole function is to weigh down the warp-weighted loom, and therefore it is important to assure the right tension of the yarn based on the weight. The loom weights were designed to complement the warp-weighted loom and to produce a specific result. Other factors also affect the tool’s usage, such as the dimensions of the fabric, the thickness of the yarn, the weaving technique, native and external traditions, and the weaver’s experience (Mårtensson, Nosch and Andersson Strand, 2009, pp.394-396). Therefore, since classifying loom weights is based on different types of observations, work has been challenging and inconsistent. Furthermore, since only a few systematic studies have been published, it is difficult to create database of shapes with a standard nomenclature (Becks, 1928; Friend, 1998; Boertien, 2009). What are missing are a comparative study and a geographical study of the loom weight remains from the various archaeological sites.

Despite the lack of published data, the concentration of heavy doughnut-shaped loom weights in a specific area of Piedmont suggests the existence of a specific textile technology: one that used a warp-weighted loom, weighed down by doughnut loom weights, even though there is still no trace of this type of loom or of the fabrics produced with it. Hence, the question remains of what technology was employed for this kind of warp-weighted loom with giant doughnut loom weights. Published literature, however, focuses principally on loom weight sets of standard shape, small or light doughnut-shaped loom weights, pyramid loom weights, and disc-shaped loom weights, which were all applied to the warp-weighted loom with the usual anchoring system to the warp threads. Only one example of a warp-weighted loom utilizing heavy loom weights is mentioned in a study focusing on the giant loom weights from Sardinia, especially those dating after the Late Iron Age (Melis, 2014, pp.94–112). This study proposes a warp-weighted loom with a mobile lower beam which is weighted down by two heavy loom weights attached to a rope. In this case the warp threads are not attached directly to the loom weights, but to a secondary beam. A reconstructive illustration included in the study by Alfaro Guiner (1984) of a loom from Sardinia depict a type of warp-weighted loom used for making sprang in the Iberian Peninsula (See Figure 2, Guiner, 1984, p.108). The author suggested that a warp weighted loom with a mobile lower beam would have produced certain local types of interlaced textiles.

Nonetheless, Guiner (1984) claims that a weaving loom of this type could have also been used to weave a simple fabric, as is suggested by studies on Viking textile art and on certain artifacts where the fabric appears as a kind of interlaced weave (Guiner, 1984, p.109, note with bibliography). Even in this case, the artefacts date between the Late Iron Age and the Middle Ages. Another example of a warp-weighted loom with loom weights not directly attached to the warp threads comes from a study on the cape of Orkney (UK) (See Figure 3). For the reconstruction of this loom were inserted in a beam which was then attached to another beam, around which warp threads could be wrapped. The experiment highlighted that this type of loom prevents the warp threads from wearing down and allows for the usage of thin threads. It also allows for variation of the loom weights during the weaving process according to the weaver’s needs. This is achieved by simply adding or removing loom weights during the process. It causes no damage and adds versatility (Wood, 2003, pp.171–175). It is on the basis of these studies that the double beam weaving loom with heavy doughnut-shaped loom weights from Fara Novarese was reconstructed. The weaving loom was reconstructed with the lower beam weighted down by loom weights, which were replicated based on general observations made on the type of artifact widespread in the Piedmont area, whose presence has been reported in multiple rural Roman settlements. (Garanzini, 2015, p.678; information on the cataloguing of the loom weights in the Soprintendenza deposits given by F.Garanzini).

Reconstruction of the Loom Weights

The loom weights from the Roman settlements in Northern Piedmont are either doughnut-shaped and flat or discoid in shape. It is also noticeable that they are flatter on the side on which they were rested on the work surface during their manufacture process. Sand residues suggest that the loom weights were left to dry on a sandy surface. Such a technique is still employed today in the creation of handmade terracotta. Its use has been evidenced in Tuscany for example, where kilns employing 11th century operational systems are still in use (Ricci, 2009; 2018). Other studies and experiments, however, demonstrate that various modeling and shaping techniques for the doughnut-shaped loom weights were employed in accordance with local and cultural traditions (Mårtensson et al., 2007, pp.3-17; Boertien, 2009, p.35; Boertien, 2012; Boertien, 2016; Karavidović and Sekelj Ivanćan, 2016; 2018, pp.1-4).

Three doughnut-shaped loom weights weighing 1 577 g, 1 310 g and 1 125 g respectively, and amounting to an overall weight of 4.012 g, were created. The artefacts’ refractory clay contains a type of grog characterized by clasts of various sizes (Garanzini, 2015), and is very similar to that used for building materials, such as bricks, found in the same archaeological context. In order to match the original clay as closely as possible, a refractory paste of which 85% consists of terracotta-colored clay without grog (acquired in loaves) and 15% consists of grog. The latter was made specifically for the experiment and consists of crushed handcrafted brick, recovered from the scraps of a nineteenth-century house renovation site. The brick was reduced by hammering to clasts of 5 mm in diameter or less. Filtered beige sand, of which the grains are finer than 1 mm was also added to the mix. Since refractory ceramic tends to lose on average 10 to 14% of its volume when it dries, an additional 10% of raw mix was added to the original weight for the creation of the replicas (Mannoni, 1994; Cuomo di Caprio, 2007; Levi, 2010).

Based on macroscopic observations, the loom weights appear to have been modelled using multiple techniques, and with the aid of tools such as a potter’s wheel, a stick, and a mold. In the case of the second technique, a colombino, or a 6 cm thick and 40 to 50 cm long clay roll (See Figure 4) is arranged in the shape of a doughnut and pressed in a concave mold similar to that of a bowl, but of which the diameter is greater to that of the loom weight itself (See Figure 5). The rest of the process is then undertaken on a wooden desk and the loom weight is modeled on its sides into a biconical shape. In the case of the first technique, a ball of clay, created by tapping the clay with the palm of the hands, was placed on the wheel. The central hole was created by using a stick, of about 2 cm in diameter. Vertical pressure and rotational movements are used to widen the hole and the final refinements are rendered with the fingers.

It is uncertain that the original loom weights had been fired in kiln. The coloring is homogeneous even though there are slight traces of blackening, that could result from drying near a fire place, or from the soil acidity. Sections indicate that the clay appears like a brick and it is clear that any present abrasions or cracks were caused by wear due to use while weaving. In this experiment, air drying was selected, because it is adaptable with the characteristics observed on the originals.

For the purpose of this research, the three loom weights will be referred to as LW1, LW2 and LW3. However, it is important to note that the following loom weight catalogues describe the original loom weights from Fara Novarese.

LW1 Loom Weight Fara Novarese catalogue (See Figure 1, on right)

Discoid shaped fictile specimen, with a doughnut-shaped outline and flat base. The central hole has vertical walls and an abrasion on one side. The ceramic body: hard and orange in color, includes minerals characterized by sharp edges and grog. There is an engraved symbol in the shape of 3/4 circle with a central dot. Diameter 15,1 cm; hole diameter 2,4 cm; thickness 5,8 cm; weight 1.577 g.

Reproduction of LW1

As well as being the heaviest of the three loom weights, it differs from the others because of its shape. The type of refractory ceramic employed nevertheless remains identical to that of the other two specimens.

For this loom weight, with a dry weight of 1.577 g, a wet mixture of 1.735 g was produced consisting of 1.475 g (85%) of raw clay and 260 g (15%) of grog. The mixture obtained was shaped and wedged to remove air bubbles. It was then formed into a spherical shape on the basis of the original proportions, and adding an additional 0.5 cm. The paste was then transferred onto the potter’s wheel to refine the shape. The hole was made using the thumb to create a flared and rounded shape. Finally, the doughnut-shaped loom weight was removed from the wheel, and the surface was manually smoothed in order to render a more regular shape. The symbol was reproduced manually, using the finger nail for the circle, and a small stick for the central dot. The symbols engraved on doughnut-shaped loom weights vary, with most common being Xs, crosses, circles and crossed lines. The latter are thought to be indicators on the type of weave to be woven, or of the decorative motif. Therefore, it is probable that these symbols indicated where the loom weight had to be placed on the weaving loom to create a certain decorative motif. Thus, it can be deduced that the weavers either produced the loom weights, or instructed the figuli (ceramic artisans) on which symbols to engrave on the loom weights. (The ongoing debate on the subject is very heated, summarized in Antolini & Marengo 2012, previously cited). Simple engraved symbols, like that on LW1 can be found on even the basic doughnut loom weights dating from the Iron Age, perhaps to indicate a set of loom weights or to distinguish the placement on the warp-weighted loom (Boertien, 2012). It can be assumed that the heaviest loom weights were placed in specific positions, such as the selvedge position, to be able to regulate the weaving process (Mårtensson, Nosch and Anderson Strand, 2009; Boertien, 2012, 10–21; Grömer, 2016, 111). The circular symbol on LW1 appears to have been engraved on fresh clay, and potentially served to indicate that this was the heaviest of the three in the set. In this experiment, the loom weight was placed on the weaving loom without taking into consideration this engraved symbol. Once completed, loom weight LW1 was left to dry for approximately thirty days, in the shade, and placed flat on top of a wooden surface and covered with cotton fabric on which small amounts of sand were spread. The cotton fabric was chosen because it facilitated ventilation but protected the loom weight from sudden changes in temperature and possible shattering.

LW2 Loom Weight Fara Novarese catalogue (See Figure 1, on left)

Discoid shaped fictile specimen, with an irregular, biconic shaped outline and flat base. The central hole has vertical walls, and a slightly flared upper border, with an abrasion on one side. The ceramic body: hard and orange in color, including minerals characterized by sharp edges and grog. Diameter 16.3 cm; hole diameter 5 cm; thickness 5.2 cm; weight 1.310 g.

LW2 Reproduction

LW2 is the second heaviest of the three discussed loom weights in. It differs from LW1 in its slightly biconical shape on both sides. This means that the cross section thickness of the outline has sharp edges, and is less rounded than the classic doughnut-shaped loom weight. Nevertheless, the material, size, diameter and thickness are almost identical. The loom weight was made of a raw mixture weighing 10% more than the original 1.310 g, thus 1.441 g. Of the 1.441 g, 1.225 g (85%) consisted of clay and 216 g (15%) consisted of grog. A 6 cm thick cylinder was modelled by manually wedging the clay to remove all trapped air. A 6 cm thick cylinder was modeled by wedging and pressed inside an 18 cm diameter bowl shaped mold. The work process was completed on the desk, by rotating the doughnut loom weight on either side, thus obtaining the biconic outline. Throughout this process, it was observed that the central hole of the loom weight developed with an uneven surface as opposed to the hole created with the stick on the wheel, as with LW1. However, the result of the external outline is rather successful, as it reflects the smooth and angular characteristics of the original loom weight’s outline (See Figure 7). It cannot be ruled out that molds were used to shape the doughnut loom weights. In this experiment, the mold was successful for this purpose. During the modeling process, a 1 cm margin was added to the measurements to allow for the loss of 10% volume once dry. No engraved symbols appear on LW2 and thus the replica’s surface was undecorated. The loom weight was then left to dry for thirty days on a wooden surface, covered with white cotton fabric and lightly sprinkled with filtered sand.

Drying Process of LW1 and LW2

Only once the loom weights were dry was it possible to review how much of the original volume had been lost, and to confirm whether the 10% loss was an accurate estimate. In the end, the volume of the two loom weights was reduced by 14%. LW1 weighed 1.346 g once dry, as opposed to 1.577 g, losing 231 g and approximately 1 cm in size. LW2 weighed 1.123 g once dry, instead of 1.310 g, losing 187 g and also approximately 1 cm in size. Therefore, the sizes and dimensions came to be almost equal to the original, though the reproductions were lighter in weight. From the required overall weight of 4.012 g, the joint weight of LW1 and LW2 was subtracted, resulting in 1.543 g. This was determined to be roughly the weight necessary for LW3, meaning that the raw refractory ceramic mixture had to weigh 14% more. Thus, 216 g was added to the 1.543 g mix, resulting in a loom weight weighing a total of 1.759 g, prior to drying.

LW3 Loom Weight Fara Novarese catalogue (See Figure 1, on the middle)

Discoid shaped fictile specimen, with an irregular biconic outline and flat base. The central hole has vertical walls, and a slightly flared upper border, with an abrasion on one side. The ceramic body: hard and orange in color, includes minerals characterized by sharp edges and grog. Diameter 15,4 cm; hole diameter 2,8 cm; thickness 5 cm; weight 1.125 g.

LW3 Reproduction

LW3 is the lightest doughnut-shaped loom weight of the three discussed pieces. It has a slightly irregular biconal shape, and a smaller central hole than that of LW2: 2.8 cm as opposed to the latter’s 5 cm. It also has rounder edges than LW2. The color is of a lighter orange shade, presenting a slight yellow-orange tinge all across the surface, which could in fact be a thinner layer of clay spread on the loom weight, prior to firing. It appears to have been immersed in a more liquid clay, to refine and smoothen the surface before firing. However, this kind of thin clay veil remains significantly abraded and therefore could also be a consequence of usage, light exposure, soil oxidation or a firing characteristic. To recreate the loom weight LW3, a potter’s wheel was used, starting from a ball of refractory clay, calculated as in previous experiments with 85% clay and 15% grog, and using the same ingredients. The modeling was achieved by rotating the wheel whilst attempting to press down with the fingers, and thus flattening the sides and rendering the irregular biconic outline. In order to perforate the loom weight, the same 2 cm stick was used to exert pressure vertically, during the rotation procedure, whilst simultaneously tilting slightly to widen the central hole. Compared to the modeling process of LW2, the pottery wheel allows for the creation of loom weights with equal and even outlines, even though the execution and result was less successful than when using the bowl mold (See Figure 8). It is believed that, most likely, both a mold and a wheel were used to complete the modeling and shaping of the loom weight. The drying method remains the same to that of the previous experiments.

Reconstruction of the Weaving Loom

The second phase of the project concerned the reconstruction of the weaving loom. The reconstruction was done by using manual tools similar to those used during the Roman period. The wood, also similar to that originally used, was gathered from a small forest on a hill. Because the type of wood had to be resistant, flexible and easy to work with, ash, beech and hornbeam were selected.

To begin with, the quadrangular bases were created (See Figure 9). They measure 30 cm sideways and consisted of four panels of seasoned pine. Pine was the only material purchased for the reconstruction due to its dry and resistant qualities and because it further ensures the final stability of the weaving loom. The quadrangular panels were glued together, two by two, and manually perforated centrally to insert the vertical poles. Two vertical poles of 165 cm in length (See Figure 15) were worked with a small planer blade to obtain a clean, smooth and aesthetically pleasing surface. The two poles were then perforated on both sides using an awl, gouge, and wood gimlet, at regular and symmetrical distances. These holes were used to accommodate the wooden pins which support the beams of the weaving loom. After this, the vertical poles placed within the hole were anchored to the bases with metal fasteners and decorative nails. These elements were both present in the Roman period in wooden buildings and building constructions in general. A small connecting beam between the two vertical supports connects the bases and allows the weaving loom to be adjusted, controlling the front position and the alignment of the entire structure. The 80 x 6 cm connecting beam was made from seasoned wood that was perforated and connected to the bases with hand-carved wooden pins (See Figure 9). Two beams, measuring 140 cm and 125 cm were cut and planed to support the warp and loom weights. The wood chosen for the beams is especially suitable for the tension and movement of a weaving loom, due to its elastic characteristics. An additional beam of 125 cm long was made using the same technique and was placed on the back of the weaving loom on the opposite side of the lower beam. The lower beam and the back beam were tied tightly on the poles with a plant fiber rope (See Figure 11). All the pins used in the reconstruction of the weaving loom were hand carved, with some featuring decorative carvings. They were made to measure with the placement hole and serve to support the beams (See Figure 10). The two middle pins were forked, in order to carry out the standard back and forth motion of the heddles.

Function of the Weaving Loom

This weaving loom consists of a combination of two types of weaving looms: the warp-weighted type and the double beam type. Two of the three reconstructed giant loom weights, LW1 (1,346 g) and LW3 (1,543 g), were not attached to the warp threads, but were rather used to weigh down the lower beam on which the warp is wrapped.

These loom weights are hung on the sides of the beam, weighing down the warp without stressing or damaging the threads (See Figure 12). Finally, the third weight, LW2 (1,123 g) is placed at the center of the rear beam, to stabilize the area and prevent tension and vibration (See Figure 12, on the center). The warping process happens by winding the threads around the beams. On the back of the weaving loom, the threads cross the horizontal cord, as is done in typical warp preparation techniques for the double beam loom. This is done to take advantage of the length of the wrapped warp, and to obtain a longer fabric. When the warp is made, the lower beam with the loom weights is located above the holding pins. In this way, the threads do not move and are not too tight, and all the warping takes place with the beam in this stop position. Once this phase is completed, the beam is moved under the pins it weighs down the warp, putting it in the correct tension for the weaving process (See Figure 11). The weaving process proceeds from top to bottom, starting the work without selvedge (See Figure 13). The selvedge is made by plaiting the final fringes once the work is finished and removed from the weaving loom. In case the work has to be interrupted, the beam must be adjusted to the stop position. While no side selvages were made during this experiment, creating a fabric with decorative selvages is planned for future experiments. Regardless, in Roman tabby weaves, such as tunics, the sides of the fabric were reinforced by applying the cords or braiding the fringes, after having completed the weaving process (Pertegato, 2019, pp.4-8).

Reflections on the Experiment

The limitations of the weaving loom reconstructed for this experiment (See Figure 15) relate to the difficulty experienced in adjusting the shed of the warp to the passage of the weft thread. It is however still possible to manage this by better adjusting the heddles. With future research, it will be possible to test the feasibility of creating more complex patterns with multiple heddles. The advantages of conducting this experiment include the possibility of modifying the warp, using threads of different thicknesses, adding or removing warp threads, changing the weight by adding additional loom weights by using sprang weaving techniques, and finally of being able to preserve the wrapped warp threads from wear. It is important to note that LW1, LW2 and LW3 are exact copies of the original artefacts in terms of shape, but differ in terms of weight. In the case of the LW1 replica, the weight is equal to that of the original LW2 artefact; in the case of the LW2 replica, the weight is equal to that of the original LW3 artefact; and in the case of the LW3 replica, the weight is the same as the original LW1 artefact. Nonetheless, the total weight of the three loom weight replicas does not differ from that of the original three specimens.

Conclusion

Research inspiring this weaving experimentation includes in particular two types of weaving loom. The first is of the sprang technique, in which two loom weights were placed on the lower beam (See Figure 2). The second type is the weaving loom of experiment of the Orkney Hood hooded cloak, where the loom weights weighed down the warp indirectly (See Figure 3). Guiner (1984, Fig. 2) describes the sprang weaving technique as using certain heavy loom weights and textiles discovered in Spain, and compares these findings to the loom for sprang, on which two loom weights were applied, which are however dated to 800 AD, found in the Oseberg ship burial in Norway. The same type of loom is also proposed for the Iron Age giant loom weights found in Sardinia (Melis, 2014). Also relevant to this study is an interesting experiment, conducted in Marle at the Musée des Temps Barbares (Nice, 2009) on Merovingian weaving looms from Goudelancourt, France. The loom employed in this experiment was modelled on the Oseberg loom. The looms employed in this experiment were modeled on the Oseberg loom and on the drawdown loom in the Carolingian Utrecht Psalter.

The Roman double beam weaving loom is represented in the low relief of the Transitorio Forum and in the fresco of the Aurelii Hypogeum in Rome (See Figure 14) (Bisconti, 2011; Broudy, 1993, figs. 3.12, 3.13). The quadrangular bases thus represented inspired the bases of the weaving loom reconstructed for this research. As no traces of pole digs caused by the resting of the weaving looms were found in the Fara Novarese excavations, it is therefore believed that the weaving loom rested on the floor. In the experiment of the Orkney Hood hooded cloak, mentioned previously, the fabric for the Orkney Hood was reproduced with a weaving loom with warping applied on an additional mobile beam, weighed down by a lower beam with loom weights inserted through their central hole (Wood, 2003, pp.171–175). The weaving loom reconstructed (See Figure 15) for the purpose of this research is inspired by the two systems, incorporating the technology of the fixed double beam weaving loom with the mobile technology of the warp-weighted loom, which are two technologies and systems known during the Roman period and present within the Italian territory. Without excluding local alternatives, dictated by previous and persistent traditions, it can be stated that a variety of textile products existed during the Roman period. The circulation of finished and raw products, "traveling" technologies and weaving techniques were also due to the relocation of weavers, freedmen or slaves, all coming from different textile cultures. Nonetheless, local Roman culture also maintained an antecedent identity. Warp-weighted looms with pyramidal loom weights were not adopted in the Novarese and northern Piedmont areas but the doughnut-shaped loom weights of the Bronze Age persisted. In the absence of a perfectly preserved and functioning Roman weaving loom, one must build previous experiments and studies, but also propose alternative innovations. Ultimately, perhaps this experiment and research will lead the way for other types of interpretations of the Roman weaving loom.

Acknowledgements

Francesca Garanzini (Soprintendenza Archeologia Belle Arti e Paesaggio per le Province di Biella Novara Verbano Cusio Ossola e Vercelli, Italy).

Karina Grömer, Ingrid Schierer, from NHM and Wien University, experimental archaeology masterclass of Asparn an der Zaya, open-air museum Mamuz, Austria.

Country

- Italy

Bibliography

Alfaro Guiner, C. 1984. Tejido y Cesteria en la Península Ibérica. Historia de su Técnica y Industrias desde la Prehistoria hasta la Romanizacion, Bibliotheca Praehistorica Hispana 21. CSIC Instituto Español de Prehistoria Madrid.

Antolini, S. & Marengo S. M. 2012. Scrivere i pesi da telaio. La documentazione dell’Italia romana. In Sylloge Epigraphica Barcinonensis, X, 149–168.

Basso, P., Busana, M.S. and Bonato, E. 2016. Pesi da telaio romani della Venetia tra archeologia, epigrafia. In Giovannini, A. (Ed.) Made in Roma and Aquileia. Marchi di produzione e di possesso nella società antica. Catalogo della Mostra, Roma, Aquileia, 13 Maggio 2016-31 Maggio 2017.

Beck, H.C. 1928. Classification and Nomenclature of Beads and Pendants. Archaeologia, Volume 77: 1–76 DOI: < https://doi.org/10.1017/S0261340900013345 >

Bergamini, S. 2009. Le figurazioni impresse sui pesi da telaio romani del Basso Po: note e ipotesi di uno studio. In Quaderni della Bassa Modenese, 23, 1(55) : 5–40.

Bisconti, F. 2011. Ipogeo degli Aureli: alcune riflessioni e qualche piccola scoperta. In Bisconti, F. (Ed.) Le pitture delle catacombe romane. Restauri e interpretazioni, Todi : 47–58.

Boertien, J.H. 2009. A Simulation Experiment in the Context of a Technological Study of Levantine Iron Age Clay Loom Weights. Leiden Journal of Pottery Studies, 25, 31–45.

Boertien, J.H. 2012. Weaving at Tell Mazar. The Loom Weights. In Yasmine, K. & Van der Steen, E., Tell el-Mazar II. Excavations on the Mound 1977-1981, Field 1. BAR International Series 2430. Oxford: Archeopress, 59–72.

Boertien, J.H. 2017. Loom weights as a research tool. In BAF-Online: Proceedings of the Berner Altorientalisches Forum 2016. [online] Available at < http://ancientworldonline.blogspot.nl/2017/02/new-open-access-journal-bad-online.html > [Accessed 20 March 2019]

Bonetto, J. 2012. Agricoltura e allevamento ovino: orizzonti mediterranei e territori cisalpini. In Busana, M.S. & Basso, P. (Eds) La lana nella Cisalpina Romana. Economia e società. Atti del convegno Padova-Verona 18-20 Maggio 2011, 27, Padova: University Press. pp. 107-126.

Broudy, E. 1993. The Book of Looms: A History of the Handloom from Ancient Times to the Present, UNPE.

Busana, M., Cottica, D. and Basso, P. 2012. La lavorazione della lana nella Venetia. In La lana nella Cisalpina romana. Economia e società. Atti del Convegno Padova-Verona 18-20 maggio 2011, Antenor Quaderni 27, Padova University Press, pp.383–433.

COLVMELLA, Lucio Giunio, De Rustica. Loeb Classical Library, vol. 361, Harvard University Press, Cambridge, Mass., 1941.

Cumbo, C. 2015. Ulisse e le sirene. Confronti figurativi e tematiche nella prima arte cristiana tra scultura, pittura, mosaici e arti minori", in De Medio Aevo, vol. 8, n. 2 pp. 45–64

Cuomo di Caprio, N. 2007. Ceramica in Archeologia 2. Antiche tecniche di lavorazione e moderni metodi di indagine. Roma.

Friend, G. 1998. Tell Taannek 1963-1969, III/2. The Loom weights. Publications of the Palestine Institute of Archaeology Excavations and Survey. Birzeit University.

Garanzini, F. 2015., V.6 Varia, I pesi da telaio. In E. Destefanis (Ed.) Il priorato cluniacense dei Santi Pietro e Paolo a Castelletto Cervo. Scavi e ricerche 2006-2014, 678–682.

Gleba, M. 2012. Lo sviluppo delle fibre di lana nell’Italia Preromana. In Busana, M.S. & Basso, P. (Eds) La lana nella Cisalpina Romana. Economia e società. Atti del convegno Padova-Verona 18-20 Maggio 2011, 27, Padova: University Press.

Gostenčnik, K. 2012. Austria: Roman Period. In Gleba, M and Mannering, U. (Eds) Textiles and textile production in Europe from Prehistory to AD 400, Ancient Textiles Series 11, Oxford 2012, 65–90.

Gostenčnik, K. 2014. Textileproduktion in der Austria Romana. In Grömer, K. (Ed), Römische Textilien in Noricum und Westpannonien im Kontest archäologischer Gewebefunde 2000 V. Chr. bis 500 n. Chr. in Österreich, Austria Antiqua 5, Uni Press Graz Verlag, 57–109.

Grömer, K. 2016. The Art of Prehistoric Textile Making. The development of craft traditions and clothing in Central Europe, Wien: Naturhistorisches Museum Wien.

Karavidović, T. and Sekelj Ivanćan, T. 2016. A loom from Virje. In Prilozi instituta za arheologiju, 33, 171–237.

Karavidović, T. and Sekelj Ivanćan, T. 2018. Understending the archaeological records: reconstructing a Warp-weighted loom. in EXARC Journal [online] Available at < https://exarc.net/issue-2018-2/ea/understanding-archaeological-record-r… > [Accessed 10 February 2019].

Larsson Lovén, L. 2013. Female Work and Identity in Roman Textile Production and Trade: a Methodological discussion. In Gleba, M. & Pásztókai-Szeöke, J. (Eds) Making Textiles in Pre-Roman and Roman Times. People, Places, Identities, Ancient Textiles Series 13, Oxbow Books, 109–125.

Levi, S.T. 2010. Dal coccio al vasaio. Manifattura tecnologia e classificazione della ceramica, Bologna.

Liu, J. 2012. Trade, traders and Guildes(?) in Textiles: the case of Southern Gaul and Nothern Italy (1st – 3rd Century AD). In Gleba, M. and Pásztókai-Szeöke, J., Making Textiles in Pre-Roman and Roman Times. People, Places, Identities, Ancient Textiles Series 13, Oxford and Oakville, Oxbow Books, 126–141.

Mannoni, T. 1994. Archeometria-geoarcheologia dei manufatti. Venticinque anni di archeologia globale, 5, Genova.

Mårtensson, L., Andersson, E., Nosch, M.L. and Batzer A. 2007. Technical Report, Experimental Archaeology,Part 3 Loom weights, 2007. Tools and Textiles – Text and Contexts. Research programme, The Danish National Research Foundation’s, Centre for Textile Research, University of Copenhagen.

Mårtensson, L., Nosch, M.-L. & Andersson Strand, B. 2009. Shape of Things: understanding a Loom Weight. In Oxford Journal of Archaeology, 28/4, 373–398.

Martuscelli, E. 2003. La fibra naturale che ha segnato la storia di popoli e nazioni. L’arte della lana dalla Preistoria alla Rivoluzione Industraile. Roma: Consiglio Nazionale delle Ricerche.

Melis, M.G. 2014. Lo strumentario tessile della Preistoria. I pesi da telaio della Sardegna. In Quaderni Lapairs 1, Sassari. pp. 75-126.

Mennella, G. 2000. Un negotiator vestiarius cisalpinus et transalpinus a Fara Novarese, In Epighaphica, 62, 125–136.

Mennella, G. 2003. Percorsi e percorrenze dei mercanti romani tra il Po e il mondo transalpino: tre tipologie a confronto. In Cresci Marrone G. and Tirelli M. (Eds), Produzioni, merci e commerci in Altino pre romana e romana. Atti del convegno, Venezia, 12-14 Dicembre 2001, Roma, 389–399.

Nice, A. 2009.Tissage et archéologie à Goudelancourt-Les-Pierrepont (Aisne). In Revue Archéologique de Picardie, 1/2, 55–61.

Panella, S. 1998. Anelli di grandi dimensioni. In Adige ridente 1998, 371–376.

Pertegato, F. 2019. Vestiarium. Le vesti per la liturgia nella storia della Chiesa. Antichità e Medioevo. eBook Goware 2019.

Quercia, A. 2019. Purpurae Vestes 2019, Abstract Poster in Conference [online] Available at < https://purpureaevestes.weebly.com/uploads/5/7/8/0/57809013/abstractsv13.pdf > [Accessed 7 October 2019]

Ricci, F. (Ed.). 2009. La civiltà del cotto. Arte della terracotta nell’area Fiorentina dal XV al XX secolo, Firenze.

Ricci, F. 2018. Le tecniche artigianali del cotto. Collezione Terracotta Impruneta. [online] Available at < https://www.youtube.com/watch?v=Af2-xYJFTFk&ab_channel=StoriediAlternan… > [Accessed 17 November 2020].

Rottoli, M. 2005. Tessuti e intrecci dalla Preistoria al Medioevo: recupero, conservazione e analisi. Le esperienze del laboratorio di archeologia dei Musei Civici di Como. In Atti del Convegno: Intrecci vegetali e fibre tessili da ambiente umido. Analisi conservazione e restauro, Trento-Riva del Garda 28-30 maggio 2003, 62–92.

Spagnolo Garzoli G. and Gambari F.M. (Eds). 2004. Tra terra e acque. Carta Archeologica della Provincia di Novara, Provincia di Novara Editore.

Spagnolo Garzoli, G. and Gabutti, A. 2015. Fara Novarese (scavi 2013), S.P. 299 variante a nord dell’abitato (maggio e ottobre) a margine della S.P. della Valsesia. In Notiziario, Quaderni della Soprintendenza Archeologica del Piemonte, n. 30, Torino, 345–348.

Valentino, M. 1997. La Montagnola di Marineo. Pesi da telaio e Oscilla. In Archeologia e territorio. Palermo: Palumbo, 197–207.

Wood J. 2003. The Orkney Hood an Ancient Re-cycled textile. In Downes J. & Ritchie A. (Eds) Sea change: Orkney and Northern Europe in the Later Iron Age AD 300-800, Balgavies, Angus: The Pinkfoot Press, 171–175.