The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

Birch Bark Glue and its Potential Use in Neanderthal Clothing: A Pilot Study

Evidence that Neanderthals had mastered the production of birch bark tar as an adhesive has generated important and timely debate concerning behavioural complexity. Increased resolution of the data on palaeo-climatic conditions has also brought into sharp focus the need for hominins living in high latitudes to possess complex cultural mechanisms to deal with cold environments. Whilst evidence for fire is readily available for Neanderthals, evidence for clothing remains obscure. Due to taphonomic constraints only indirect evidence for clothing can be examined. The recovery of eyed needles only from sites related to Homo sapiens, along with a longstanding presumption that Neanderthals were less culturally adaptive has resulted in a belief that Neanderthals lacked complex, tailored clothing. However, if hominins in high latitude, glacial environments needed complex clothing for survival, and other technologies might serve in place of the eyed needle, it is possible to re-focus the debate on Neanderthal clothing and cognition. In this paper we present an experimental pilot study which suggests that birch bark glue was a possible component of the Neanderthal technological repertoire for making tailored and, perhaps more importantly, waterproof garments.

Introduction

Homo neanderthalensis (Neanderthals) are known to have occupied Eurasia from as early as 430 ka (Arsuaga et al., 2014) until their eventual extinction circa. 40 ka (Higham et al., 2014). Recognition of the considerable challenges associated with life in the mid to high latitudes occupied by these people has grown considerably in recent years. Research (Hosfield 2016; Rodríguez et al., 2021) has highlighted the effects of increased seasonal contrast, heightened day-night temperature contrasts, and the problem of cold exposure for early hominins in these latitudes.

The modern human susceptibility to dangers posed by the cold, with hypothermia induced if an individual’s core temperature drops just 1.5 °C from 37.5 °C to 35 °C (Parsons, 2003), has demonstrated that modern humans are unable to survive in high latitudes without the assistance of tailored clothing – clothing that is constructed from multiple separate parts that provides protection from the elements as well as insulation through an “air-capture system” (White, 2006: 559) of sealed seams (Ewing and Darwent, 2018; Gilligan, 2010). However, only recently has the possibility of Neanderthals utilising similar technology been seriously considered in the archaeological literature (Hosfield 2016). Detailed reconstructions of Neanderthal mobility and thermo-regulatory capacities have indicated that Neanderthals frequently suffered extreme cold (Aiello and Wheeler, 2003). Many scholars now consider it highly likely that survival during these periods was only possible with the addition of some type of clothing (Hosfield, 2016; Rodríguez et al., 2021; Sørensen, 2009; White, 2006). Despite this, the exact technologies employed for clothing construction during this time are unknown. Recognisable sewing technology is absent from the archaeological record until 50 ka (Shunkov et al., 2020), and is never found in contexts associated with Neanderthals. The current lack of identifiable sewing technology presents an interesting opportunity to explore other possible clothing construction methods. This study will provide a preliminary examination of the potential of birch (Betula sp.) bark tar as an alternative technology for the creation of complex tailored clothing and to assess its strength as a prehistoric fabric glue.

A Cousin in the Cold

The past decades have seen a revolution in our understanding of palaeoclimates. A combination of ocean floor sediment cores and Greenland ice cores have allowed for palaeoclimatic reconstruction setting out not only warm and cold periods, known as Marine Isotope stages (MIS), but also periods of rapid, millennial-scale climate change within such stages and an estimation of broad temperature ranges. While Neanderthals are known to have been present in Europe from MIS 13 to MIS 3, the period of interest for this research is the time when Neanderthals were manufacturing and using adhesives in the form of birch bark tar. Currently the earliest evidence for the use of birch bark tar is confined to the period from MIS 6 onwards (Mazza et al., 2006). Table 1, below, gives an overview of the relevant climate conditions which Neanderthals would have encountered in these periods.

| MIS Stage | Date (ka) | Description |

| 6 | c. 191-130 | An intense glacial period with extended and long-lasting ice sheets covering all of northern Europe (Churchill, 2014). Temperatures in central France likely to have been 13 °C cooler than at present, with 600-800 mm less precipitation. Difficult to reconstruct seasonal temperatures due to lack of suitable data. |

| 5 | 130-71 | Usually subdivided into five stages (Shackleton, 1969). The first of these is MIS 5e, 128-116 ka, an intensely studied interglacial period generally thought to have been wet and warmer than present conditions (Salonen et al., 2018). MIS 5 phases d-a are believed to have alternated between warm and cold periods, beginning the gradual descent into full glacial conditions, with MIS 5c almost returning to MIS 5e conditions, and MIS 5a in turn rising almost to the conditions of MIS 5c. |

| 4 | c. 71-57 | Glacial period seeing expansion of the northern ice sheets to almost same extent as during MIS 6 (Churchill, 2014). Van Andel and Tzedakis (1996) suggests that temperatures in France during this period were between 12-13 °C cooler than at present, and that rainfall was 650-800 mm less than current. |

| 3 | c. 57-29 | Categorised as a warm period but climatic instability at this point was high. Unlikely to have reached high temperatures of MIS 5e and the present day (Churchill, 2014) |

| 2 | c. 29-14 | Glacial period. Climate stabilised more than in MIS 3 with cold conditions. |

Table 1. Overview of climatic conditions for MIS-6-2. All dates taken from Lisiecki and Raymo (2005).

During MIS 6 and MIS 4, Neanderthals would have experienced extreme climatic oscillations, and extreme low temperatures estimated to have been 12-13 °C cooler than the present (Van Andel and Tzedakis, 1996). Although it is clear that cold periods had a profound influence on Neanderthal distribution (Hublin and Roebroeks, 2009; Skrzypek et al., 2011; Wales, 2012), including a decrease in site numbers and greater use of southern refugia, such as at Pech de L’Aze IV and Roc de Marsal in south-western France (Hodgkins et al., 2016), evidence for the presence of Neanderthals in higher latitudes such as in Norfolk, UK and near Cologne, Germany demonstrates that they were able to cope with extreme low temperatures (Uthmeier et al., 2011).

Historically, several aspects of Neanderthal anatomy have been interpreted as adaptations to cold weather. A robust stature combined with shorter relative limbs has been interpreted within the context of Bergmann (1847) and Allen’s (1877) rules; the reduction in relative surface area presenting smaller radiative surfaces by which to lose heat. An enlarged Neanderthal nasal cavity has also been proposed as adaptation for heating cold air prior to deep inhalation (Churchill 1998; Cf. Rae et al., 2011).

While some biological adaptations to cold are no doubt present in Neanderthals, Aiello and Wheeler (2003) argue that these advantages may have been small and insufficient for survival, especially when the effects of windchill are considered. Further biological responses in the form of winter fur cover or regulation of metabolism, as suggested by MacDonald (2018), also present significant problems to an individual’s thermoregulation, especially during periods where basal metabolic rate (BMR) is reduced, such as at rest (Sørensen, 2009), or alternatively because of overheating during energetic activity. In this context, additional biological solutions seem unlikely and, in many ways, echo the common trope of viewing Neanderthals as more biologically than culturally adapted (Moser 2018). With biological adaptation rejected, we must consider what cultural adaptations Neanderthals needed to deal with cold and changeable environments and what archaeological evidence exists for such cultural adaptations.

The most important cultural adaptation needed in cold environments is the control of fire (Clark and Harris 1985). Archaeological evidence for the control of fire pre-dates Neanderthals with hearth features dated to 500 ka at Boxgrove, in the UK (Gowlett et al., 2005), and 700 ka at Gesher Benot Ya’ aqov, in Israel (Alperson-Afil 2008). For Neanderthals, there is both direct evidence (Albert et al., 2012; Aldeias et al., 2012; Roebroeks and Villa 2011) and indirect evidence (Aranguren et al., 2018; Sorensen et al., 2018) to suggest that their pyro-technological expertise was an advanced and crucial part of their cultural adaptation.

Fire, however, cannot keep an individual warm when away from camp. Staying warm without fire or fixed shelter represents a significant challenge and in effect requires humans to create a portable insulated environment in the form of clothing (Gilligan, 2010; White, 2006). Using computational modelling to assess the minimum clothing coverage needed by Neanderthals from MIS 5e to the Holocene, Wales (2012) estimated that Neanderthals would have required up to 80 % coverage in the coldest European regions, and 25 % in warmer areas during cold seasons, implying that some level of clothing use was obligatory for most Neanderthals. Sørensen (2009) goes further, arguing that coverage during sleep equivalent to a large mammoth skin would have been essential almost all year round even during the relatively warmer Eemian interglacial (MIS 5e).

Neanderthal in a three-piece suit

Given that almost all Palaeolithic age clothing will have been manufactured from organic material, surviving archaeological evidence for clothing is currently unknown. We must therefore focus on the indirect evidence for clothing that might be preserved. Commonly examined in studies of early clothing is the evidence for personal adornment and the arrangement of ornaments including ivory beads and armlets found in the excavated burials of modern humans, such as the Prince at Arene Candide (Pettitt et al., 2003) or the three individuals at Sunghir (Trinkaus and Buzhilova 2018), have been argued to suggest the existence of a well-developed, decorated and tailored clothing by 35 ka, with the distribution of beading found in these funerary arrangements implying that they may have originally been stitched onto cloth and worn as fitted clothing. As yet, there is no evidence for this type of behaviour before this date. However, evidence for Neanderthals processing hides, both with stone tools (Kimball et al., 2017; Rots, 2009), and bone tools (Baumann et al., 2020; Soressi et al. 2013) is well documented. The process of scraping hides indicates an important use of the skins, with the most logical use being the preparation of animal skins with insulative properties (Gilligan, 2010).

With good evidence for Neanderthals exploiting animal hides for some form of insulation the focus shifts to asking how such fabrics might have been put together. Eyed needles have never been found associated with Neanderthals, which has been interpreted by Gilligan (2007) as indicative of a limitation in tailoring skills and the production of nothing more than simple, draped (cape-like) clothing. In the same vein, Wales (2012), despite presenting evidence that Neanderthals needed to cover 70-80 % of their body during cold periods, presumes that this could be achieved without any specialised tailoring.

In contrast to Gilligan (2007) and Wales (2012), White (2006), has argued that the only way for hominins to survive in Doggerland during MIS 3 was to create a portable insulative environment in the form of tailored garments. Sørensen (2009) echoes these findings, with both studies highlighting that an absence of needles does not mean an absence of piercing technology as stone or bone splinters were likely to have been widely available. White (2006) also draws attention to the fact that simple draped clothing, such as that proposed by Gilligan (2007), was unlikely to have been suitable for undertaking physical activity, a key aspect of Neanderthal life.

Collard et al. (2016) have approached this same problem through a comparison of faunal data from Neanderthal and Homo sapiens sites. Although species associated with clothing production are associated with both groups of hominins, frequencies of leporid, canid and mustelid bones were found to be higher at H. sapiens sites. Ethnographic data from modern groups living in cold conditions suggest that the fur of these animals is often used as fur trim (Oakes et al., 1995) due to its superior insulative properties offering enhanced protection for the extremities and face (Cotel et al., 2004). The differential frequencies of faunal remains at Neanderthal and H. sapiens sites are interpreted by Collard et al. (2016) as indicative of increased fur usage by modern humans. Whilst the authors argue that this supports the idea that Neanderthals were unable to create complex clothing, some modern Inuit groups do not use fur trim on their clothing (Birket-Smith, 1929; Oakes, 1991; Cotel et al., 2004). To discount the possibility that Neanderthals made tailored clothing based solely on a more limited presence of animals associated with fur trims is not justified.

In summary, while there is agreement that Neanderthals needed clothing for survival in mid to high latitudes, there is disagreement on the complexity of this clothing, how well tailored it might have been and the practical techniques used in manufacture. Whilst White (2006) and Sørensen (2009) correctly note that Neanderthals had easy access to piercing implements other than needles, no consideration has yet been given in the archaeological literature to alternative technologies for early seam construction. For example, today, fabric glues are popular for those without access to sewing equipment or expertise as well as being used by outdoor clothing manufactures as a means of waterproofing seams (Radhakrishnan and Kumari, 2017). Looking for analogues in the Neanderthal archaeological record opens a new avenue of research and new hypotheses concerning the manufacture of Neanderthal material culture and systems for thermoregulation.

Neanderthals in a sticky situation

Neanderthals are known to have used at least three types of natural adhesive, pine resin (sometimes mixed with beeswax; (Degano et al., 2019), bitumen (Boëda et al., 1996, Cârciumaru et al., 2012) and a tar extracted from birch bark (Mazza et al., 2006). Birch bark tar is both the most commonly found archaeologically and from significantly earlier in the archaeological record.

The earliest evidence for birch bark tar comes from the Italian MIS 6 site of Campitello, where two flakes have their entire proximal half covered in tar (Mazza et al., 2006). Other examples have also been found from MIS 5e and MIS 5a sites in Germany (Pawlik and Thissen, 2011; Wragg Sykes, 2015), and at 50 ka (MIS 3) in the Netherlands (Niekus et al., 2016). Given these factors of abundance and age, and the likely ease of access to birch in Palaeolithic environments, the experiments here focus on birch bark tar.

Birch bark pitch/ tar is a sticky adhesive made through the anaerobic distillation of birch bark to approximately 340-400 °C (Wragg Sykes 2015). Like other primitive adhesives it has usually been associated with hafting technologies (Barham 2013; Mazza et al., 2006). As well as research on its use in hafting and the cognitive requirements for its creation and use (Schmidt et al., 2019), research into birch bark tar has considered its physical properties (Kozowyk et al., 2017a; Kozowyk and Poulis, 2019), manufacture methods (Kozowyk et al., 2017b; Schenck and Groom, 2018), chemical make-up (Koller et al., 2001), conditions of archaeological preservation (Kozowyk et al., 2020), and its performance when used as an adhesive on wood and stone (Kozowyk et al., 2017a).

The numerous examples of Neanderthal birch bark tar imply that it may have been a developed technology used by Neanderthals from approximately 200 ka (MIS 6) onwards. As noted above, climatic reconstructions show that the use of birch bark tar coincided with a cold stadial period, and that such harsh climatic conditions would have generated significant selective pressure for complex tailored clothing. Here we advance and test the hypothesis that birch bark tar offered a suitable fabric glue that could have been employed by Neanderthals in the manufacture of tailored clothing.

Introduction to experimentation

Modified lap-shear tests have been chosen to test the potential use of birch tar in primitive clothing seam construction. Across repeated trials, different birch tar recipes were used to bond two pieces of leather together. After a period of drying (7 days), the glued leather strips were loaded to failure to generate an experimentally determined strength for that specific glue recipe.

The modified lap-shear test

Figure 1 shows how the samples were prepared prior to loading. Commercial goat leather from offcuts was used, which, whilst not being directly comparable to hides which Neanderthals may have used, provided a uniform set of fabric samples in sufficient quantity for this pilot study. The limitations presented by the use of these modern commercial offcuts meant that tests were restricted to only exploring leather sides which did not include hair. The presence of hair within the bonded area may affect the strength of the bond, an idea which should be explored in future work. The use of a metal grommet, whilst again a contemporary element, prevents the leather samples from ripping and helps to generate a controlled, even loading on the seam that is consistent across experiments.

To test the strength of the adhesive bond, one piece of leather (side A) was secured horizontally in a vice. A mechanical weight gauge (kg) was then placed into the metal grommet at one end with the other end secured to a lever (See Figure 2). The lever was then drawn back at a steady, constant rate until the seam failed. Each test was videoed so that the exact breaking strain could be obtained.

Making the birch bark tar

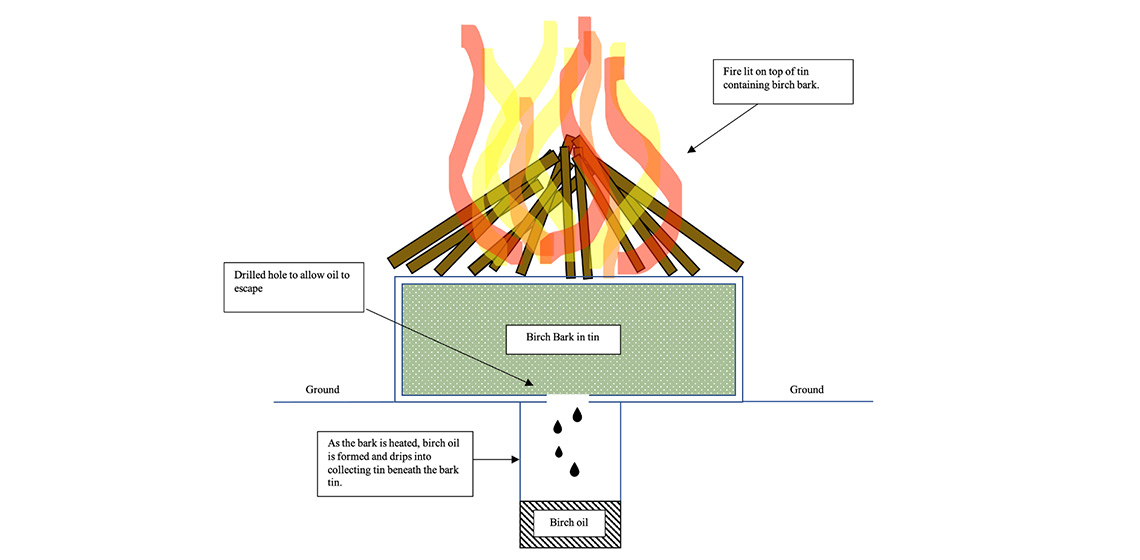

A mixed birch oil was manufactured using the double pot method (using metal pots), with bark harvested from a number of birch trees (Betula pendula, Betula papyrifera) during November – March 2020-21 (See Figure 3). This method produces a refined birch oil which can then be reduced to usable tar by heating to between 105-120 °C to drive off excess water and other volatiles (Kozowyk et al., 2020). While this method was not available to Neanderthals, who are thought to have used methods which bypass the oil stage in directly producing a tar (Kozowyk et al., 2017b), the double pot method offers a reliable method of creating a large homogeneous sample needed for controlled experimentation (Rageot et al., 2019). Producing the tar using more authentic and primitive methods might generate different results and this will require further experimentation in future. As with the use of goat leather, the focus here has been on the production of a large sample of comparable experimental data to establish some form of baseline.

Birch tar recipes

While birch tar on its own may offer sufficient functional properties, the knowledge that other primitive adhesives both require and contained other elements (Niekus et al., 2019; Barham, 2013; Van Gijn and Boon, 2006) motivated an exploratory phase of testing different recipes.

The additives chosen for research in this phase were beeswax, holly ash and rosin. Beeswax is known to have plasticising effects when added to natural adhesives such as resin and gum glues, making them less brittle (Kozowyk et al., 2020; Wadley et al., 2009). Holly (Ilex aquifolium) ash was chosen because of its strongly alkaline properties which was known from previous undescribed experiments by the authors of this study to set birch tar into a hard compound. Rosin is a refined, non-volatile form of resin (Kozowyk et al., 2020). When used alone, it is extremely brittle, but when added in small quantities is theorised to help the tar to set more solidly as well as potentially acting as a form of temper.

| Additive | Percentage Added |

| 100% Tar | N/A |

| Holly Ash | 20% |

| Beeswax | 20% |

| Rosin | 20% |

| Beeswax and Holly Ash | 10 %, 10 % |

| Beeswax and Rosin | 10 %, 10 % |

| Rosin | 100 % (No Tar) |

Table 2. Combination and percentage of materials added to the tar during the exploratory phase.

| Additive | Force of pull (N) |

| 100 % tar | 3,43 |

| Holly ash | 62,27 |

| Beeswax | 13,73 |

| Rosin | 2,45 |

| Beeswax and Holly Ash | 39,72 |

| Beeswax and Rosin | 34,32 |

Table 3. Results of the exploratory tests.

To explore the potential effects of different additives on the birch tar, several one-off exploratory recipes (See Table 2) were mixed using an electric hot plate to produce a low viscosity tar to aid mixture. Kozowyk et al. (2017a) found that when performing lap shear tests with plywood, adding 30 wt% charcoal to pine tar resulted in immediate failure. With this as a guide, approximately 1g of tar, 20 % (approx. 0.2 g, 16 wt%) of each additive was added. It was hoped that this proportion would affect significant chemical or structural changes needed to compare the different recipes and not result in immediate failure.

Results (See Table 3) indicate that the mixture containing holly ash was noticeably stronger than the other combinations. The combination of holly ash and beeswax is the second strongest recipe, suggesting more clearly that holly ash is the additive providing the strongest bond. As a result, holly ash was chosen as the additive for further examination.

Birch bark tar mixed with holly ash and beech ash

With the holly ash recipe identified as most suitable, we have tested a series of different percentages of holly ash additive to determine the strongest and most reliable bond. Using the same experimental procedures as the exploratory phase, we prepared and tested fifteen samples of 10 wt%, 20 wt%, 30 wt% and 40 wt% holly ash, and four samples of 50 wt% and 60 wt% holly ash. Each recipe using 17g were made for the samples of 15 and 4.5 g for the samples of four. Once applied to the leather, samples were allowed to dry for seven days, at room temperature.

Beech (Fagus sylvatica) ash was also selected as a possible additive due to its known and observable alkaline properties, forming a soap when mixed with fat and water. Four samples were made at 20 wt%, and two at 40 wt% and 60 wt% and tested following the same procedure as described above. These Beech ash experiments were exploratory in nature and designed only to provide a point of comparison to the holly ash samples.

In total, 68 holly ash and eight beech ash samples were lap-shear tested. Three of the holly ash samples (two of the 30 wt% and one of the 40 wt% group), experienced leather failure (due to variability in the leather) before the adhesive bond broke despite not reaching the maximum force achieved by others within their sample group. These samples were therefore excluded from analysis as this implies a fault with the leather rather than any extreme bond strength.

Bond strength of holly ash and birch tar

Table 4 below provides the breaking force data for each sample along with summaries of each recipe. Comparisons of the mean force (N), shows the 10 wt% group was the weakest, x = 36.41 N (sd. 11.02) and the 20 wt% was the strongest, x = 112.09 N (sd. 34.06). Interestingly, the average strength decreased with the 30 wt% group, x = 91 N (sd. 27.79), but then increased with the 40 wt% recipe to x = 104.79 N, (sd. 41.21).

With a normal distribution demonstrated (Shapiro-Wilk test: 10 wt%, p = 0.9982; 20 wt%, p = 0.4079; 30 wt%, p = 0.8582; 40 wt%, p = 0.07748), unpaired t-tests were used to compare the different recipes. These revealed a significant statistical difference between the 10 wt% and 20 wt% groups (p = <0.005) with no strong statistical difference demonstrated between the 20 wt% and 30 wt% groups (p = 0.08288) or 30 wt% and 40 wt% groups (p = 0.3155).

| Wt % Holly Ash | Force of Pull (N) | Wt % Holly Ash2 | Force of Pull (N)3 | Wt % Holly Ash4 | Force of Pull (N)5 | Wt % Holly Ash6 | Force of Pull (N)7 | Wt % Holly Ash8 | Force of Pull (N)9 | Wt % Holly Ash10 | Force of Pull (N)11 |

| 10 | 41,19 | 20 | 100,52 | 30 | 137,3 | 40 | 87,77 | 50 | 165,74 | 60 | 110,33 |

| 10 | 36,78 | 20 | 70,61 | 30 | 48,84 | 40 | 83,36 | 50 | 147,6 | 60 | 34,81 |

| 10 | 25,5 | 20 | 112,29 | 30 | 83,36 | 40 | 100,03 | 50 | 33,34 | 60 | 16,67 |

| 10 | 38,25 | 20 | 120,14 | 30 | 107,39 | 40 | 26,48 | 50 | 38,25 | 60 | 93,17 |

| 10 | 43,64 | 20 | 57,86 | 30 | 38,74 | 40 | 20,1 | ||||

| 10 | 33,83 | 20 | 86,3 | 30 | 100,52 | 40 | 116,7 | ||||

| 10 | 29,91 | 20 | 72,57 | 30 | 76,98 | 40 | 135,34 | ||||

| 10 | 32,85 | 20 | 158,87 | 30 | 127,98 | 40 | 144,16 | ||||

| 10 | 58,35 | 20 | 145,14 | 30 | 75,02 | 40 | 154,46 | ||||

| 10 | 15,69 | 20 | 147,11 | 30 | 85,32 | 40 | 138,77 | ||||

| 10 | 42,17 | 20 | 124,55 | 30 | 93,66 | 40 | 109,84 | ||||

| 10 | 50,51 | 20 | 75,02 | 30 | 103,46 | 40 | 146,12 | ||||

| 10 | 25,99 | 20 | 110,33 | 30 | 104,44 | 40 | 102,48 | ||||

| 10 | 45,5 | 20 | 160,83 | 40 | 101,5 | ||||||

| 10 | 25,99 | 20 | 139,26 | ||||||||

| Min. | 15,69 | Min. | 57,86 | Min. | 48,84 | Min. | 20,1 | Min. | 33,34 | Min. | 16,67 |

| Max. | 58,35 | Max. | 160,83 | Max. | 137,3 | Max. | 154,46 | Max. | 165,74 | Max. | 110,33 |

| Mean | 36,41 | Mean | 112,09 | Mean | 91 | Mean | 104,79 | Mean | 96,2 | Mean | 63,75 |

Table 4. Force of pull (N) for each successful holly ash sample tested. Minimum, maximum and mean values are provided for each sample group.

While there appears to be no strong statistical difference between the recipes over 20 wt% it is notable that there is a drop in mean strength and that, in the case of the 40 wt% group, this is accompanied by a greater standard deviation (See Figure 4). This leads us to hypothesise that a recipe mix in excess of approximately 20 wt%, while still capable of producing some strong seams, produces a less reliable glue overall. The limited data from the 50 wt% and 60 wt% samples also support this (See Figure 5), with the largest range of readings observed in the 50 wt% group and one of the lowest breaking forces recorded in the 60 wt% group. Whilst this hypothesis concerning variance and reliability may be refuted with larger samples, we expect that the increase in strength observed between the 10 wt% and 20 wt% will remain statistically meaningful.

Bond strength of beech ash and birch tar

Although there has been an insufficient number of experiments conducted on recipes using beech ash to allow for statistical analysis, the results (See Figure 6 and Table 5) suggest a similar situation to that observed with holly ash. A large increase in strength was recorded with the 40 wt% recipe, followed by a significant drop in strength with the 60 wt% recipes.

| Wt % Beech Ash | Force of Pull (N) | Wt % Beech Ash2 | Force of Pull (N)3 | Wt % Holly Ash | Force of Pull (N)4 |

| 20 | 16,18 | 40 | 102,09 | 60 | 30,89 |

| 20 | 15,2 | 40 | 118,66 | 60 | 25,99 |

| 20 | 15,69 | ||||

| 20 | 22,07 | ||||

| Min. | 15,2 | Min. | 102,09 | Min. | 25,99 |

| Max. | 22,07 | Max. | 118,66 | Max. | 30,89 |

| Mean | 17,29 | Mean | 110,38 | Mean | 28,44 |

Table 5. Force of pull (N) for each successful beech ash sample tested. Minimum, maximum and mean values are provided for each sample group.

Chemical analysis of results

Controlled experiments using reagent grade sodium hydroxide have previously revealed that strong alkalis have the ability to alter the physical properties of birch tar, changing it from a viscous liquid into an extremely tough solid. Chemical analysis of both holly and beech ash, using SEM EDS, revealed that these compounds contained significant quantities of potassium, which is highly likely to be present as an oxide (See Appendix 1 and 2 for full elemental breakdown). When potassium oxide is exposed to moisture it will form the strong alkaline potassium hydroxide. Compositionally the holly ash exhibited approximately 26 % potassium, whilst the beech ash exhibited approximately 15 % potassium by mass. This equates to the holly ash containing almost 43 % more potassium than the beech ash, which may explain why the beech ash sample strength appeared to peak with roughly twice as much ash by mass when compared to holly ash.

Discussion

The experimental results clearly demonstrate that birch tar, when mixed with selected high alkaline wood ash, has potential as an effective leather glue as might be required in the manufacture of tailored complex clothing. The complexities of aceramic birch tar production (Kozowyk et al. 2017b), along with the mixing of specific wood ash needed to produce a functional fabric glue presents it as a relatively complex technology similar to those known from certain African Middle Stone Age sites (Wadley et al., 2009).

Whilst is it clear that holly ash has a profound impact on the bond strength of birch tar when used as a leather glue, with an increase of over 75 N between the mean averages for the 10 wt% and 20 wt% groups, the plateau and increased variance in strength exhibited by higher ash percentages was unexpected. Previous studies of prehistoric compound adhesives such as those by Kozowyk et al. (2016) and Kozowyk et al. (2017a) demonstrated that a high degree of precision is needed to produce the optimum ratio between additives in both rosin-based and pine tar adhesives: additives negatively affect bond strength if incorporated in too great a quantity. Indeed, the addition of charcoal to pine tar has been found to cause an adhesive bond to fail before testing at 30 wt%, with the strongest bond forming at only 10 wt% (Kozowyk et al., 2017a). The comparatively lower levels of precision needed with the holly ash and birch tar recipe potentially offers a simpler technology.

The results of the limited beech ash experiments seem to follow Kozowyk et al.’s (2017a) pine tar strength tests more closely, with the addition of 40 wt% ash significantly improving the adhesive strength followed by a sharp drop in strength with 60 wt% recipes. The 60 wt% beech ash samples were still marginally stronger than the 20 wt% group, implying that the addition of too much beech ash, while appearing to negatively affect the structure of the adhesive, does provide the required alkalinity to increase its strength. Further testing of the beech ash recipes is needed to ascertain whether the current observations are accurate.

Comparing the holly and beech ash recipes demonstrates that both can produce relatively strong bonds, although the beech ash results are limited in number. The 40 wt% mean averages for both ash types (104.79 N for the holly ash and 110.38 N for the beech ash) demonstrates clear similarities in strength between the two recipe groups, suggesting that Neanderthals would not necessarily have had to select for one specific species of tree to transform into ash. However, the significant difference between the strength of 20 wt% recipes for holy and beech ash (an average of 112.09 N for holly ash compared to 17.29 N for beech ash) suggests that holly ash might have been a more appealing additive because it reaches a stronger bond earlier and because this strong bond is sustained over more wt% groups than the beech ash.

There is clear archaeological evidence to show that Neanderthals were capable of selecting for materials with specific properties. The Schöningen spears (dated to circa 350 ka) provide a good example with Neanderthals systematically manufacturing the point of these spears from the root of a 50–60-year-old spruce tree, perhaps the hardest part of the tree (Schoch et al., 2015). At the 171 ka site of Pogetti Vecchi in Italy, Neanderthals were also using fire as a tool to make working the extremely hard boxwood easier (Aranguren et al., 2018). It is entirely plausible that, along with the required knowledge for the production of birch bark tar, Neanderthals possessed both the pyro-technological skill and knowledge of the properties of different tree species to selectively burn holly for its ash.

The discovery of the transformative properties of ash when added to birch tar could easily have occurred by accident with ash from the fire used to make birch tar added as an attempt to increase the volume of a precious resource. Alternatively, the addition of ash could have occurred simply due to an accident during manufacture. Holly wood may have been particularly desirable to Middle Palaeolithic mobile hunters as it can be burnt green, producing a fierce, long-lasting heat. For mobile hunters, such as Neanderthals, not having to cache wood to season would be advantageous, allowing a group to move around without concerns over access to suitable firewood. The affordances of holly as a firewood increase the chances of Neanderthals encountering the transformative properties of its ash. Indeed, the alkaline nature of fresh holly ash is notable through the effect of saponification, with any moisture on the hands reacting with fats from the skin to form a weak soap. While this would not betray the specific nature of any transformative effect it may have marked the ash as something different in the mind of the Neanderthal.

Birch bar tar and clothing manufacture

As discussed, birch tar clearly changes its properties when holly ash is added, increasing significantly in strength until it reaches a plateau after 20 wt% ash is added. As such, this birch bark tar recipe seems to demonstrate evidence of some potential use as a small-scale fabric glue. Inferences about the real-world capacity of birch tar to be used in clothing manufacture can be made if we compare the results of this small-scale experiment to more traditional methods of seam construction.

Ethnographic analysis of nineteenth century Inuit clothing has determined that stress-bearing seams in these garments were generally constructed using overcast stitches (Ewing and Darwent, 2018). Seams constructed using this method not only conserve material well but show a remarkable degree of consistency in high level strength across a wide variety of thread types (Ewing and Darwent, 2018). The similarity in methods used for strength testing by Ewing and Darwent (2018) allow us to compare the strength of seams constructed using our birch tar recipe and sewn seams. As shown in Figure 7, there is a clear divergence in effectiveness between the two methods. While birch tar demonstrates impressive strengths, it underperforms when compared to the overcast stitches. There is no overlap between the two groups, with the highest performing birch tar samples unable to reach the strengths of even the lowest performing stitched samples. The implication is that whilst birch tar clearly has some potential as a fabric glue, with it occasionally requiring more than 165 N of force to pull the leather samples apart, the superiority of the overcast stitches demonstrates that it is a better strength option than birch tar for seam construction if this technology is available.

Alongside strength, there is a difference in the variability of the strength of the bonds. Although some of the sewn groups have high outliers, these samples are far less variable than the birch tar samples tested here (See Figure 3). The variable strength of a birch tar bond is potentially its most significant limiting factor. Reliability of seam strength is an integral element of any effective garment and is likely to pose significant problems to people living highly active lifestyles if absent (Hosfield, 2016; Niven et al., 2012; White, 2006). It may be that factors in our manufacture process resulted in the increased variance and in doing so demonstrate a lack of expertise which might reasonably be expected to be present in a group with cultural knowledge of the process. One variable of interest was drying time. Our samples were dried at room temperature and in some cases took a week to dry. It is possible that drying the samples faster, for example by a fire, could produce different results.

The Potential for Birch Bark Tar as a Fabric Glue

Comparisons between sewn seams and birch tar glued seams appear to show that birch tar recipes may have been an unsuitable and potentially overly complicated method for clothing construction. This does not mean, however, that birch tar was not used on textiles or in the manufacture of clothing at all. Numerous potential avenues for use remain open.

In cool conditions, the bodily extremities, such as hands and feet, are the parts most at risk of cold damage such as frostbite (Gilligan, 2010). Mapping by Wales (2012) indicates that Neanderthals were frequently living in areas that had a >75 % likelihood that their hands and feet would need to have been covered. The tar recipe trialled here may have been more appropriate for the smaller pieces of clothing needed to cover these body parts. Whilst Inuit groups have developed highly sophisticated sewing techniques, to achieve waterproofing in which the epidermis of the leather is not pierced on both sides (Pharand, 2012), waterproofing any stitched seam represents both a significant advantage as well as a significant challenge. It could be that a birch tar seam offers a solution to this challenge. It is perhaps more likely that a stitched seam might be sealed using birch tar, much like modern outdoor clothing’s use of pliable waterproof seam tape (Radhakrishnan and Kumari, 2017). The addition of birch tar to a sewn seam would simultaneously seal the stitching holes, waterproof the seam, and protect the stitching from rotting (Rots 2013). As noted, eyed needle technology is currently unknown for Neanderthals, and that while other technology is more than possible it may result in larger holes in the fabric being joined. This would potentially produce both a weaker sewn seam and also creates more need for a seam sealant such as birch tar to provide waterproofing. With high quality waterproof clothing conferring a significant advantage to any hunter gathers experiencing the climatic conditions experienced by Neanderthals, we believe that hypothesising that such a technological innovation existed is warranted and deserves further consideration.

Conclusions

Discussions and research concerning Palaeolithic clothing are only just beginning. Whilst the degree of complexity of clothing has been discussed by numerous authors (Collard et al., 2016; Gilligan, 2010; Sørensen, 2009; White, 2006), an acute lack of archaeological evidence to inform researchers of how such clothing might have been constructed has meant that any discussion of the techniques of Neanderthal clothing construction remains limited and largely determined by our assumptions about the necessity for sewing techniques.

Experimental investigations into potential alternative techniques for seam construction can therefore provide exciting new insights into the Palaeolithic world. The results of this study shows that birch bark tar does have the capacity to increase considerably in strength when 20 wt% or more holly ash is combined with liquid tar. Moreover, whilst comparison to experimental overcast stitches indicate that the tar does not reach the strengths of more traditional sewn seams, the increase in strength raises possibilities that need investigation. Future research may flow in multiple directions; examining a wider range of birch tar ‘recipes’ will help to establish whether there are refinements that could be made to improve the strength of the tar even further. Ultimately, experimental reconstructions of garments using the strongest birch bark tar combination as a seam adhesive will provide the best data on how the seams hold up to more realistic use. Additionally, whilst pine tar appears highly sensitive to contamination (Kozowyk et al., 2017a), birch tar is less sensitive an adhesive when holly ash is added. Should more testing of beech ash samples support this finding, we might infer that Neanderthals deliberately chose to make birch bark tar over pine tar, for which we have limited Neanderthal examples of, because of its decreased sensitivity.

Recognition of the importance of coping with thermal stress is becoming more prevalent in the archaeological literature, with widespread acknowledgement that clothing was likely a necessity to survive in the changeable climatic environment of Palaeolithic Eurasia (Macdonald, 2018; Rodríguez et al., 2021; White, 2006). Although this study does not claim that birch bark tar in this form can withstand the stresses of daily wear, its possibilities for use in seam construction clearly suggest that we should understand that early adhesive use may not have been restricted to hafting alone.

Keywords

Bibliography

Aiello, L. C. and P. Wheeler 2003. Neanderthal Thermoregulation and the Glacial Climate. In: T. H. van Andel and W. Davies eds. Neanderthals and Modern Humans in the European Landscape During the Last Glaciation.. Cambridge, McDonald Institute for Archaeological Research: pp. 147-166.

Albert, R. M., F. Berna and P. Goldberg 2012. Insights on Neanderthal fire use at Kebara Cave (Israel) through high resolution study of prehistoric combustion features: Evidence from phytoliths and thin sections Quaternary International, 247, pp.278-293.

Aldeias, V., P. Goldberg, D. Sandgathe, F. Berna, H. L. Dibble, S. P. McPherron, A. Turq and Z. Rezek 2012. Evidence for Neandertal use of fire at Roc de Marsal (France). Journal of Archaeological Science, 39(7), pp.2414-2423.

Allen, J. A. 1877. The influence of physical conditions in the genesis of species. Radical Review, 1, pp. 108-140.

Alperson-Afil, N. 2008. Continual fire-making by Hominins at Gesher Benot Ya'aqov, Israel. Quaternary Science Reviews, 27(17-18), pp.1733-1739.

Aranguren, B., A. Revedin, N. Amico, F. Cavulli, G. Giachi, S. Grimaldi, N. Macchioni and F. Santaniello 2018. Wooden tools and fire technology in the early Neanderthal site of Poggetti Vecchi (Italy). Proceedings of the National Academy of Sciences of the United States of America, 115(9), pp.2054-2059.

Arsuaga, J. L., I. Martinez, L. J. Arnold, A. Aranburu, A. Gracia-Tellez, W. D. Sharp, R. M. Quam, C. Falgueres, A. Pantoja-Perez, J. Bischoff, E. Poza-Rey, J. M. Pares, J. M. Carretero, M. Demuro, C. Lorenzo, N. Sala, M. Martinon-Torres, N. Garcia, A. A. de Velasco, G. Cuenca-Bescos, A. Gomez-Olivencia, D. Moreno, A. Pablos, C. C. Shen, L. Rodriguez, A. I. Ortega, R. Garcia, A. Bonmati, J. M. B. de Castro and E. Carbonell 2014. Neandertal roots: Cranial and chronological evidence from Sima de los Huesos. Science, 344(6190), pp. 1358-1363.

Barham, L. 2013. From Hand to Handle: The First Industrial Revolution. Oxford, Oxford University Press.

Baumann, M., H. Plisson, W. Rendu, S. Maury, K. Kolobova and A. Krivoshapkin 2020. "The Neandertal bone industry at Chagyrskaya cave, Altai Region, Russia." Quaternary International, 559, pp. 68-88.

Bergmann, C. 1847. Uber die verhaltnisse der warmeokonomie der thiere zu ihrer grosse. Göttinger Studien.: pp.595-708.

Birket-Smith, K. 1929. The Caribou Eskimos: Material and Social Life and Their Cultural Position. Report of the Fifth Thule Expedition 1921-24, 5, pp. 1-2.

Boëda, E., J. Connan, D. Dessort, S. Muhesen, N. Mercier, H. Valladas and N. Tisnerat 1996. Bitumen as a hafting material on Middle Palaeolithic artefacts. Nature, 380(6572), pp. 336-338.

Cârciumaru, M., R. M. Ion, E. C. Nitu and R. Stefanescu 2012. New evidence of adhesive as hafting material on Middle and Upper Palaeolithic artefacts from Gura Cheii-Rasnov Cave (Romania). Journal of Archaeological Science, 39(7), pp. 1942-1950.

Churchill, S. E. 2014. Thin on the Ground: Neandertal Biology, Archaeology, and Ecology. Iowa, John Wiley & Sons Inc.

Clark, J. and J. Harris 1985. Fire and its Roles in Early Hominid Lifeways. African Archaeology Review, 3(1), pp. 3-27.

Collard, M., L. Tarle, D. Sandgathe and A. Allan 2016. Faunal evidence for a difference in clothing use between Neanderthals and early modern humans in Europe. Journal of Anthropological Archaeology, 44, pp.235-246.

Cotel, A. J., R. Golingo, J. E. Oakes and R. R. Riewe 2004. Effect of ancient Inuit fur parka ruffs on facial heat transfer. Climate Research, 26(1), pp.77-84.

Degano, I., S. Soriano, P. Villa, L. Pollarolo, J. J. Lucejko and Z. Jacobs 2019. Hafting of Middle Paleolithic tools in Latium (central Italy): New data from Fossellone and Sant'Agostino caves (vol 14, e0213473, 2019). Plos One, 14(10), e0223714

Ewing, D. R. and C. M. Darwent 2018. Sinew thread production and stitch properties in Arctic Alaskan clothing construction. Alaskan Journal of Anthropology, 16, pp. 1-23.

Gilligan, I. 2007. Neanderthal extinction and modern human behaviour: the role of climate change and clothing. World Archaeology, 39(4), pp. 499-514.

Gilligan, I. 2010. The Prehistoric Development of Clothing: Archaeological Implications of a Thermal Model. Journal of Archaeological Method and Theory, 17(1), pp. 15-80.

Gowlett, J. A., J. Hallos, S. Hounsell, V. Brant and N. C. Debenham 2005. Beeches Pit: Archaeology, Assemblage dynamics and Early Fire History of a Middle Pleistocene Site in East Anglia, UK. Eurasian Prehistory, 3(2), pp.3-38.

Higham, T., K. Douka, R. Wood, C. B. Ramsey, F. Brock, L. Basell, M. Camps, A. Arrizabalaga, J. Baena, C. Barroso-Ruiz, C. Bergman, C. Boitard, P. Boscato, M. Caparros, N. J. Conard, C. Draily, A. Froment, B. Galvan, P. Gambassini, A. Garcia-Moreno, S. Grimaldi, P. Haesaerts, B. Holt, M. J. Iriarte-Chiapusso, A. Jelinek, J. F. J. Pardo, J. M. Maillo-Fernandez, A. Marom, J. Maroto, M. Menendez, L. Metz, E. Morin, A. Moroni, F. Negrino, E. Panagopoulou, M. Peresani, S. Pirson, M. de la Rasilla, J. Riel-Salvatore, A. Ronchitelli, D. Santamaria, P. Semal, L. Slimak, J. Soler, N. Soler, A. Villaluenga, R. Pinhasi and R. Jacobi 2014. The timing and spatiotemporal patterning of Neanderthal disappearance. Nature, 512(7514), 306-309.

Hodgkins, J., C. W. Marean, A. Turq, D. Sandgathe, S. J. P. McPherron and H. Dibble 2016. Climate-mediated shifts in Neandertal subsistence behaviors at Pech de l'Aze IV and Roc de Marsal (Dordogne Valley, France). Journal of Human Evolution, 96, pp. 1-18.

Hosfield, R. 2016. Walking in a Winter Wonderland? Strategies for Early and Middle Pleistocene Survival in Midlatitude Europe. Current Anthropology, 57(5), pp. 653-682.

Hublin, J. J. and W. Roebroeks 2009. Ebb and flow or regional extinctions? On the character of Neandertal occupation of northern environments. Comptes Rendus Palevol, 8(5), pp. 503-509.

Kimball, L. R., T. S. Coffey, N. R. Faulks, S. E. Dellinger, N. M. Karas and N. Hidjrati 2017. A Multi-instrument Study of Microwear Polishes on Mousterian Tools from Weasel Cave (Myshtulagty Lagat), Russia. Lithic Technology,42(2-3), pp. 61-76.

Koller, J., U. Baumer and D. Mania 2001. High-tech in the middle Palaeolithic: Neanderthal manufactured pitch identified. European Journal of Archaeology, 4(3), pp. 385-397.

Kozowyk, P. R. B., G. H. J. Langejans and J. A. Poulis 2016. Lap Shear and Impact Testing of Ochre and Beeswax in Experimental Middle Stone Age Compound Adhesives. Plos One, 11(3), e0150436.

Kozowyk, P. R. B., J. A. Poulis and G. H. J. Langejans 2017a. Laboratory strength testing of pine wood and birch bark adhesives: A first study of the material properties of pitch. Journal of Archaeological Science-Reports, 13, pp. 49-59.

Kozowyk, P. R. B., M. Soressi, D. Pomstra and G. H. J. Langejans 2017b. Experimental methods for the Palaeolithic dry distillation of birch bark: implications for the origin and development of Neandertal adhesive technology. Scientific Reports, 7(1), pp. 8033.

Kozowyk, P. R. B. and J. A. Poulis 2019. A new experimental methodology for assessing adhesive properties shows that Neandertals used the most suitable material available. Journal of Human Evolution, 137, 102664.

Kozowyk, P. R. B., A. L. van Gijn and G. H. J. Langejans 2020. Understanding preservation and identification biases of ancient adhesives through experimentation. Archaeological and Anthropological Sciences, 12, 209.

Lisiecki, L. E. and M. E. Raymo 2005. A Pliocene-Pleistocene stack of 57 globally distributed benthic delta O-18 records. Paleoceanography, 20(2), PA1003.

MacDonald, K. 2018. Fire-free hominin strategies for coping with cool winter temperatures in North-Western Europe from before 800,000 to circa 400,000 years ago. PaleoAnthropology, 2018, pp.7 -26.

Mazza, P. P. A., F. Martini, B. Sala, M. Magi, M. P. Colombini, G. Giachi, F. Landucci, C. Lemorini, F. Modugno and E. Ribechini 2006. A new Palaeolithic discovery: tar-hafted stone tools in a European Mid-Pleistocene bone-bearing bed. Journal of Archaeological Science, 33(9), pp. 1310-1318.

Moser, S. 2018. Ancestral Images: The Iconography of Human Origins. New York, Cornell University Press.

Niekus, M. J. L. T., P. R. B. Kozowyk, G. H. J. Langejans, D. Ngan-Tillard, H. van Keulen, J. van der Plicht, K. M. Cohen, W. van Wingerden, B. van Os, B. I. Smit, L. W. S. W. Amkreutz L. Johansen, A. Verbaas and G. L. Dusseldorp 2019. Middle Paleolithic complex technology and a Neandertal tar-backed tool from the Dutch North Sea. Proceedings of the National Academy of Sciences of the United States of America, 116(44), pp.22081-22087.

Niven, L., T. E. Steele, W. Rendu, J. B. Mallye, S. P. McPherron, M. Soressi, J. Jaubert and J. J. Hublin 2012. Neandertal mobility and large-game hunting: The exploitation of reindeer during the Quina Mousterian at Chez-Pinaud Jonzac (Charente-Maritime, France). Journal of Human Evolution, 63(4), pp. 624-635.

Oakes, J. E. 1991. Copper and Caribou Inuit skin clothing production. Hull, Quebec: University of Ottowa Press.

Oakes, J., H. Wilkins, R. Riewe, D. Kelker and T. Forest 1995. Comparison of Traditional and Manufactured Cold Weather Ensembles. Climate Research, 5(1), pp.83-90.

Parsons, K. C. 2003. Human Thermal Environments. London, Taylor & Francis.

Pawlik, A. F. and J. P. Thissen 2011. Hafted armatures and multi-component tool design at the Micoquian site of Inden-Altdorf, Germany. Journal of Archaeological Science, 38(7), pp. 1699-1708.

Pettitt, P. B., M. Richards, R. Maggi and V. Formicola 2003. The Gravettian burial known as the Prince ('IL-Principe'): New evidence for his age and diet. Antiquity, 77(295), pp.15-19.

Pharand, S. 2012. Caribou skin clothing of the Igloolik Inuit. Iqaliut: Inhabit Media.

Radhakrishnan, S. and K. D. 2017. Seams for Protective Clothing-An Overview. World Journal of Textile Engineering and Technology, (3), pp.16-23.

Rae, T. C., T. Koppe and C. B. Stringer 2011. The Neanderthal face is not cold adapted."Journal of Human Evolution, 60(2), pp.234-239.

Rageot, M., I. Thery-Parisot, S. Beyries, C. Lepere, A. Carre, A. Mazuy, J. J. Filippi, X. Fernandez, D. Binder and M. Regert 2019. Birch Bark Tar Production: Experimental and Biomolecular Approaches to the Study of a Common and Widely Used Prehistoric Adhesive. Journal of Archaeological Method and Theory, 26(1), pp. 276-312.

Rodriguez, J., C. Willmes and A. Mateos 2021. Shivering in the Pleistocene. Human adaptations to cold exposure in Western Europe from MIS 14 to MIS 11. Journal of Human Evolution, 153, 102966.

Roebroeks, W. and P. Villa 2011. On the earliest evidence for habitual use of fire in Europe. Proceedings of the National Academy of Sciences of the United States of America, 108(13), pp.5209-5214.

Rots, V. 2009. The functional analysis of the Mousterian and Micoquian assemblages of Sesselfesgrotte, Germany: Aspects of tool use and hafting in the European Late Middle Palaeolithic. Quartär, 56, pp.37-66.

Rots, V. 2013. Insights into early Middle Palaeolithic tool use and hafting in Western Europe. The functional analysis of level IIa of the early Middle Palaeolithic site of Biache-Saint-Vaast (France). Journal of Archaeological Science, 40, pp.497-506.

Salonen, J. S., K. F. Helmens, J. Brendryen, N. Kuosmanen, M. Valiranta, S. Goring, M. Korpela, M. Kylander, A. Philip, A. Plikk, H. Renssen and M. Luoto 2018. Abrupt high-latitude climate events and decoupled seasonal trends during the Eemian. Nature Communications 9, 2851.

Schenck, T. and P. Groom 2018. The aceramic production of Betula pubescens (downy birch) bark tar using simple raised structures. A viable Neanderthal technique? Archaeological and Anthropological Sciences, 10(1). Pp.19-29.

Schmidt, P., M. Blessing, M. Rageot, R. Iovita, J. Pfleging, K. G. Nickel, L. Righetti and C. Tennie 2019. Birch tar production does not prove Neanderthal behavioral complexity. Proceedings of the National Academy of Sciences of the United States of America, 116(36) pp.17707-17711.

Schoch, W. H., G. Bigga, U. Bohner, P. Richter and T. Terberger 2015. New insights on the wooden weapons from the Paleolithic site of Schoningen. Journal of Human Evolution, 89, pp.214-225.

Shackleton, N. J. 1969. Last Interglacial in Marine and Terrestrial Records. Proceedings of the Royal Society Series B-Biological Sciences, 174(1034), pp.135-154.

Shunkov, M. V., A. Y. Fedorchenko, M. B. Kozlikin and A. P. Derevianko 2020. Initial

Upper Palaeolithic ornaments and formal bone tools from the East Chamber of Denisova Cave in the Russian Altai. Quaternary International, 559, pp.47-67.

Skrzypek, G., A. Wisniewski and P. F. Grierson 2011. How cold was it for Neanderthals moving to Central Europe during warm phases of the last glaciation? Quaternary Science Reviews, 30(5-6), pp.481-487.

Sørensen, B. 2009. Energy use by Eem Neanderthals. Journal of Archaeological Science, 36(10), pp.2201-2205.

Sorensen, A. C., E. Claud and M. Soressi 2018. Neandertal fire-making technology inferred from microwear analysis. Scientific Reports, 8, 10065.

Soressi, M., S. P. McPherron, M. Lenoir, T. Dogandzic, P. Goldberg, Z. Jacobs, Y. Maigrot, N. L. Martisius, C. E. Miller, W. Rendu, M. Richards, M. M. Skinner, T. E. Steele, S. Talamo and J. P. Texier 2013. Neandertals made the first specialized bone tools in Europe.Proceedings of the National Academy of Sciences of the United States of America, 110(35), pp.14186-14190.

Trinkaus, E. and A. P. Buzhilova 2018. Diversity and differential disposal of the dead at Sunghir. Antiquity, 92(361), pp.7-21.

Uthmeier, T., H. Kels, W. Schirmer and U. Böhner 2011. Neanderthals in the Cold: Middle Paleolithic Sites from the Open-Cast Mine of Garzweiler, Nordrhein-Westfalen (Germany). In: N. J. Conard and J. Richter eds. (). Neanderthal Lifeways, Subsistence and Technology. Dordrecht, Springer. Pp.

Van Andel, T. H. and P. C. Tzedakis 1996. Palaeolithic landscapes of Europe and environs, 150,000-25,000 years ago: An overview. Quaternary Science Reviews, 15(5-6), pp.481-500.

Van Gijn, A. L. and J. J. Boon 2006. Birch bark tar. In L. P. Louwe Koojimans, and P. Jongste, eds. Schipluiden: Neolithic Settlement on the Dutch North Sea Coast C. 3500 Cal BC, 261-266, Leiden, Leiden University. Pp. 261-266

Wadley, L., T. Hodgskiss and M. Grant 2009. Implications for complex cognition from the hafting of tools with compound adhesives in the Middle Stone Age, South Africa. Proceedings of the National Academy of Sciences of the United States of America, 106(24), pp.9590-9594.

Wales, N. 2012. Modeling Neanderthal clothing using ethnographic analogues. Journal of Human Evolution, 63(6), pp.781-795.

White, M. J. 2006. Things to do in Doggerland when you're dead: surviving OIS3 at the northwestern-most fringe of Middle Palaeolithic Europe. World Archaeology, 38(4), pp.547-575.

Wragg Sykes, R. M. 2015. To see a world in a hafted tool: Birch pitch composite technology, cognition and memory in Neanderthals. In: F. Webnan-Smith, M. Pope and R. Hosfield, eds. Settlement, Society and Cognition in Human Evolution: Landscapes in Mind. Cambridge, Cambridge University Press. Pp.117-137