The content is published under Creative Commons Attribution 4.0 International license

Reviewed Article:

Bringing Experimental Lithic Technology to Paleoamerican Brazilian Archaeology: Replication Studies on the Rioclarense and Garivaldinense Industries

Experimental archaeology, especially experimental lithic technology, has not yet been established as a line of research in Brazil (or most of South America). This article presents the first systematic experimental research aiming the replication of Paleoamerican (or Paleoindian) lithic industries. Experimental replication of the stemmed points from Rioclarense and Garivaldinense industries were carried out in order to better understand their original technology. This article presents the results of this experiment and the comparison of the technological attributes of the replicated points and flakes to the archaeological ones. The results lead us to a discussion on some important technological aspects of the first lithic industries of Eastern South America.

Introduction

Despite experimental archaeological approaches being well known in Brazilian archaeology since the 1970’s, it has rarely produced studies until the beginning of the 21th century. The first deep debate on the subject of experimental archaeology was provided by Miller Jr. (1975), specifically on the application of the approach to lithic technology using Corumbataí flint - typical raw material from the Rioclarense industry. In that occasion, Miller Jr. carried out flaking experiments with students in order to understand how different techniques could be applied in good quality raw materials. His work was just a first step on the experimental archaeology in Brazil. However, his research is not very well known even among Brazilian archaeologists today – a fact observed in the lack of mentions of his work in Brazilian archaeology research, including the experimental reports.

The few pieces of Brazilian research that did not focus on pottery or lithic artefacts were carried out by Aytai (1970) and Oliveira (2012), and focused on rock art, specifically engraving, while Prous (1990) researched shell-tool making, but none of them were systematic research.

Most experimental archaeology research in Brazil is focused on ceramics and are almost exclusively on the Guarani archaeological culture pottery replication (Meggers and Maranca, 1980; Dutra, 2003; Baco, 2012; Cerezer and Soares, 2013; Baco and Faccio, 2014; Soares, et al., 2015; Mattos, Paniagua and Moraes, 2017; Vidal, 2018), even though many other archaeological pottery traditions are known in the Brazilian territory. The few pieces of research that did not focus on the Guarani tradition was focused on generic pottery production (Alves, 1994), Aratú-Sapucaí culture pottery (Delforge, 2017), and on the Marajoara culture thongs1 (Rodrigues, et al., 2011).

Experimental archaeology focused on lithics is still rare, and is mostly focused on ground-stone tools from Late Holocene cultures (Prous, et al., 2002; Tenório, 2003; Silva Jr., 2005; Garcia and Silva, 2013; Souza and Lima, 2014; Fernandes, Silva and Nascimento, 2015). The few experiments that focused on lithic flaking were carried out by Rodet and Alonso (2004), in an attempt to define flake attributes for hard and soft percussion on raw materials from central Minas Gerais state. Work carried out by Prous and M. Lima (1990), Prous et al. (2010) and Rodet, Duarte-Talim and Fernandes (2013) all aimed to identify anvil percussion (bipolar flaking) features on crystal quartz from central Minas Gerais state. Some few experiments were also carried out for use-wear studies on flakes by M. Lima and Mansur (1990), Alonso (2008), and Clemente-Conte, Farias and Boëda (2017). The most recent research was carried out by Santos Jr. (2017; 2018) trying to understand historical flaked glass in slavery contexts from Northern Brazil. With the exception of Miller Jr.s’ experiments on the Corumbataí flint, no other research focused on understanding the technology of the first human groups to occupy the current Brazilian territory.

In Brazilian archaeology we refer to the period of the first hunter-gatherer cultures on the American continent as the Paleoamerican (or Paleoindian) period. For the period that dates between 11,000 cal. BP to 8000 cal. BP, six Paleoamerican cultures are already known in Eastern South America, with others yet to be defined (See Figure 1).

The Pay Paso lithic industry was defined by Suárez (2003; 2015) and was identified due to the wide presence of ‘Pay Paso points’, which present a triangular body shape with convex or straight edges and a bifurcated stem with bifacial basal reduction. In technological terms, they are only described as bifacially reduced, followed by retouching in order to shape the whole artefact. The Pay Paso industry, that appeared around 11,000 cal. BP, is not the oldest one in the region though, since the Fell Industry (13,000 to 12,000 cal. BP) and the Tigre Industry (12,000 to 11,000 cal. BP) were identified in the same sites from Northwestern Uruguay, but in older archaeological levels (Suárez, 2015).

The Garivaldinense Industry was defined by Moreno de Sousa (2019) due wide presence of ‘Garivaldinense points’, ‘Brochier points’, and a small presence of ‘Montenegro points. The Garivaldinense points are mainly defined by their triangle-shaped body with irregular or straight active edges and straight wings, straight or bifurcated stems. They have three distinct technological methods of production: [a] the bifacial reduced by selective and trespassed percussion or pressure flaking (considering “trespassed” when the flake trespass the middle part of the artefact, reducing its thickness), followed by bifacial retouch by pressure flaking; [b] the bifacial reduced by convergent percussion or pressure flaking, followed by bifacial retouching by pressure flaking; and [c] the thin flakes bifacially retouched by pressure. The Brochier points are mainly defined by having no stem and wings; small size (between 22 and 34 mm long); and tapered or lanceolate shape formed by bifacial or unifacial retouch by pressure flaking. Brochier points rarely present reduction, since agate flakes are used as blanks most of the times. The Montenegro points are defined by its triangle-blade-shaped body with serrated edges, small bifurcate stem, and systematic bifacial parallel reduction that always start from the extremities and are always finished in the middle of the point’s body. The Garivaldinense Industry dates between 11,000 and (at last) 3000 cal. BP.

The Tunas industry was defined by Moreno de Sousa (2019) due the wide presence of ‘Star points’, blade debitage, and lesminas. Lesminas are small scrapers made on blade-shaped flakes by unifacial retouch, and the name is given due the similarity of its morphological concept with ‘lesmas’ and by the fact they are blade-shaped (in Brazilian Portuguese: laminar). Star points are mainly defined by their small size – usually smaller than 36 mm long, the smallest stemmed ones from the Brazilian Paleoamerican period – the triangle-shaped body with straight or concave active edges, a bifurcated stem, and a bifacial reduction by convergent pressure flaking. The Tunas industry dates between 11,000 and 8000 cal. BP.

The Rioclarense industry (former Rio Claro Tradition) was first defined by Miller Jr. (1969; 1972) due the wide presence of stemmed points and lesmas. The lesma is a specific type of unifacial scrapper similar to the European paleolithic limaces (Bordes, 1961), but with a different pattern on its specific technological features. Lesmas are always made on large flakes by unifacial reduction, present ovalate or blade shapes, plano-convex cross-section, multiple active edges (usually one of them is in the distal or proximal extremity), they are usually 7 to 15 cm long, and thickness is smaller or equal to the width (Moreno de Sousa, 2019).

The Rio Claro Tradition concept was abandoned decades later when Brazilian archaeologists decided to associate all archaeological cultures with presence of stemmed points to only one culture known as Umbu Tradition (Prous, 1991; Noelli, 2000), regardless of the cultural diversity on those lithic assemblages.

In a recent publication we discussed the problems with the definition of the Umbu Tradition (Moreno de Sousa and Okumura, 2018) and a doctoral study on the lithic assemblages associated to it revealed a more diverse culture distribution in the Umbu associated coverage area (Moreno de Sousa, 2019). This research defined the Garivaldinense and Tunas Industry, as well as redefined the Rioclarense Industry due the identification of the lesmas and, specially, the wide presence of ‘Rioclarense’ points. The Rioclarense points are mainly defined by the triangle-shaped body with straight edges and wings, ovalate stem, and two technological types of reduction: [a]; the bifacial reduction by selective and trespassed flakes removed by percussion and [b] the bifacial reduction by parallel flaking by pressure and no retouch, followed by retouch of the active edges. The Rioclarense industry dates between 11,000 and 7000 cal. BP.

The Lagoassantense Industry (or Lagoa Santa tradition) was defined by Moreno de Sousa and Araujo (2018) by the wide presence of microliths consisting of barely retouched quartz crystal flakes, produced by diagonal slicing and opposite-platforms debitage (core-flaking) methods, and the early production of ground-axe blades. This industry dates between 12,500 cal. BP and 1,000 cal. BP.

The Itaparica Industry was defined by Schmitz (1980) due the large presence of lesmas in Central Brazil, later revealed to be present in a very wide area of Central to Northeastern Brazil, and for the lack of any kind of bifacial technology.

The presence of lesmas and stemmed points in the Amazon region is also known (Roosevelt, et al., 1996; Costa, 2009) but no studies were ever carried out in order to better understand their technology and cultural associations. In fact, Amazonian archaeology studies, unfortunately, are rarely focused on Paleoamerican cultures.

To better understand the Eastern South American lithic industries technology, our research group from the Human Evolution Studies Laboratory (LEEH), University of São Paulo (USP), has recently started to apply an experimental approach to archaeological research. This article presents the results of the first study which aimed to replicate Paleoamerican stemmed points and lesmas using the same tools (hammers and pressure flakers), methods, and techniques identified in archaeological context. We were able to find and collect the original raw materials of two lithic industries: the Rioclarense and the Garivaldinense Industry.

The flaking learning process and the Paleoamerican replication stages

In order to introduce experimental lithic technology in Brazilian archaeology, international workshops have been carried out by our Paleoamerican research group in Brazil since 2016 (see: Van Veldhuizen and Moreno de Sousa, 2016, for the event first edition review). These workshops have been presented by Professor Bruce Bradley (University of Exeter, UK) and have brought, for the first time, the basic unifacial and bifacial knapping procedures knowledge to many archaeology students and professionals.

During 2017 the author of this study carried out a complete training programme on experimental lithic technology under Dr. Bradley’s supervision at the University of Exeter (UK). It consisted of daily practice of flaking and replication of Paleoamerican and Palaeolithic artefacts for five months. In that training the author was introduced for the first time to the soft percussion and pressure flaking techniques and other technological particularities.

Back in Brazil, replication of artefacts was also carried out, but focusing in the Paleoamerican stemmed points. Considering the propositions of Ascher (1961) and Coles (1973), the following procedures were considered before the start of the Paleoamerican artefacts replication.

- To acquire a minimal level of experience on the activity to be carried out before starting it;

- To define the scope of the experiment before starting it, or else it cannot even be considered a replicant experiment, but only a generic attempt of carrying out an activity the result of which cannot be anticipated;

- To use the same raw materials available in the studied archaeological context, since the raw materials may limit the number of production methods and techniques;

- To apply as many sets of alternative methods and techniques as possible, in a way that it’s possible to eliminate the sets that do not respond as expected and add other sets that may result in something like what is desired;

- To avoid underestimating or overestimating the ability and knowledge of archaeological people at carrying out the replicated activities, since they did not necessarily possess the same knowledge and abilities on such a variety of technologies as the replicator. Additionally we might not be aware of how blind we can be about their abilities and knowledge due the lack of a more accurate (or preserved) archaeological record;

- To avoid using modern tools in the replication process, since past societies did not possess them;

- To carry out the experiment as many times as possible, since failures can be the result of lack of experience, as well as it can be a natural problem with the materials (e.g., internal fractures or intrusion, in the case of lithics);

- To look for corroborative and contradictory evidence in the previously provided technological analysis results from the archaeological assemblages, since they might suggest that the operations carried out by the experimenter are or are not the same as those carried out by archaeological groups.

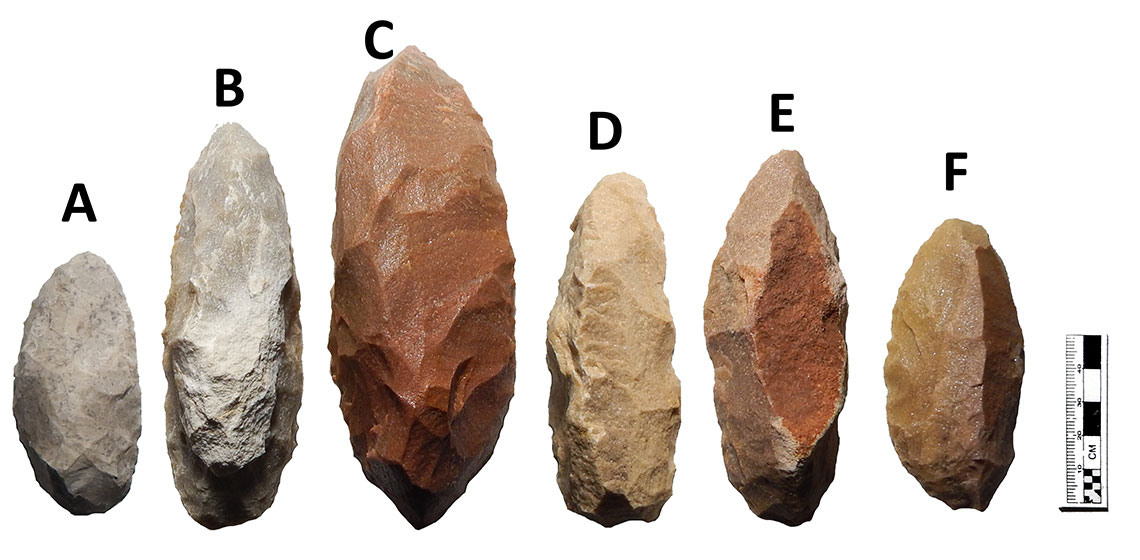

This first stage of the experiment was not systematic, since there was no focus on the use of the original raw material, but only on the perfect imitation of the metric, morphological, and technological features of the lesmas and stemmed points from Rioclarense, Tunas, and Garivaldinense industries. Only after being able to produce some perfect replicas on high quality raw materials (See Figures 2 and 3, for examples), were controlled experiments carried out, since it was certain that the necessary technical knowledge and abilities were learned.

In order to verify the technological pattern presented by the reduction flakes from Paleoamerican stemmed points, the experiment limited the production to seven attempts to produce points of each type and up to three limaces attempts, since the amount of flakes would provide a sample big enough for technological analysis and comparison to the data provided by Moreno de Sousa (2019). Unfortunately, it was not possible to replicate the Star points in the systematic experiment, since a source of the original raw material could not be found. In the case of limaces, they were reduced but not retouched, since the main interest was in comparing only the unifacial reduction flakes to the archaeological ones.

Materials and Methods

Since there is very little information on the taxonomy of the antlers used as hammers and pressure flakers, we speculated on some genus of antlered animals that could be very useful for flaking, like the deer taxa Ozoterus, Mazama and Blastocerus. However, the access to those materials in Brazil is very difficult due to national laws on traffic of wild animal parts. Because of that it was necessary to use some other available antlers that were similar in size and density to replace Ozotocerus and Blastocerus antlers. No hammer made of Brazilian wood was used, since there is no information on what kinds of wood could have been used for those purposes. The main attributes for the hammers and pressure flakers used in the research are presented in tables 1 and 2.

| Tool code | Mass (g) | Dimensions (mm) | Hammer type | Raw material |

| M1 | 114,9 | 179 x 26 x 26 | Soft | Odocoeilus antler |

| M2 | 184,6 | 117 x 49 x 34 | Soft | Moose antler |

| M3 | 172,4 | 147 x 44 x 30 | Soft | Moose antler |

| D1 | 63,6 | 61 x 45 x 16 | Hard | Quartzite pebble |

| D2 | 103,9 | 64 x 34 x 33 | Hard | Sandstone pebble |

| D3 | 119,7 | 49 x 49 x 36 | Hard | Sandstone pebble |

| D4 | 116,7 | 53 x 48 x 33 | Hard | Sandstone pebble |

| D5 | 109,8 | 55 x 53 x 25 | Hard | Quartzite pebble |

Table 1. Main attributes for soft hammers (M) and hard hammers (D) used in the experiment.

| Tool code | Handle area thickness (mm) | Tip thickness (mm) | Pressure flaker raw material | Handle raw material |

| P1 | 22 | 3 and 4 | Cervus antler | - |

| P2 | 14 | 4 | Mazama antler | - |

| P3 | 21 | 5 | Cervus antler | - |

| P4 | 24 | 7 | Cervus antler (handle) | Wood |

| P5 | 22 | 8 | Odocoeilus antler | - |

| P6 | 22 | 3 | Mammal bone | Cervus antler |

Table 2. Main attributes for pressure flakers (P) used in the experiment.

Raw materials for the lithic replicas are the same as the ones used by the studies of the archaeological cultures. Visits to the sites and surrounding areas revealed the location of those raw material sources in the case of Rioclarense and Garivaldinense industries. The Rioclarense industry is known for the high frequency of Corumbataí flint. The Corumbataí flint can be defined as a fossilized oil from Permian-Triassic silicified trunks. Botucatu silicified sandstone was mostly used to produce lesmas. The Botucatu sandstone comes from the Jurassic desert formation in Central and Meridional Brazil.

Since there is no information on the Rioclarense method for blank debitage, generic cores were used for producing some flakes. But some Rioclarense points have clear features of natural blanks – plaque shaped pebbles (Moreno de Sousa, 2019). During the debitage phase (core-flaking), it was very clear that the Rioclarense flint is formed by fossilized oil, since the strong smell of oil appears every time a flake is removed from the core, and some liquid oil was still present in some blocks (See Figure 6).

In the case of the Garivaldinense Industry, the main raw material was the Botucatu silicified sandstone. Both natural and flake blanks were used in the experiment, since no debitage method information is known yet for this industry.

Flakes from replicas were sampled in order to identify the attributes from different techniques (soft percussion, hard percussion, pressure) and to verify if they are technologically similar to the archaeological flakes found in Caetetuba and Alice Boer, two Rioclarense associated sites, and Garivaldino, a Garivaldinense associated site (Moreno de Sousa, 2019). Table 3 presents the typical features of reduction flakes from those sites during the period they were occupied. Both the Alice Boer and Garivaldino sites were occupied simultaneously, between 9000 and 7000 cal. BP. The Caetetuba site flakes correspond to dates between 11,000 and 9000 cal. BP, since this is the only period when points and lesmas were identified. It is important to notice that both Caetetuba and Alice Boer sites are associated to Rioclarense Industry due the presence of the same artefact types (lesmas and Rioclarense Points). However, there is an inversion on the frequency of those artefacts in each site. Caetetuba site presents 10 lesmas and 5 points, while Alice Boer presents 6 lesmas and 23 points. Caetetuba has more lesmas and Alice Boer has more points, what could explain the difference seen in the main flake features (See Table 3).

| Attributes | Caetetuba site 11,000 – 9000 cal BP (Rioclarense) | Alice Boer site 8500 – 7000 cal BP (Rioclarense) | Garivaldino site 9000-8000 cal BP (Garivaldinense) |

| Mass | 1 – 16,6 g | 0,6 – 11,6 g | 0,9 – 2,3 g |

| Total length | 11 – 25 mm | 24 – 46 mm | 16 – 26 mm |

| Maximum width | 11 – 25 mm | 19 – 39 mm | 17 – 27 mm |

| Maximum thickness | 2 – 4 mm | 3 – 11 mm | 3 – 5 mm |

| Platform shape | Round (68%) | Round (23%) Straight (20%) | Straight (44%) |

| Platform surface | Flat (68%) | Flat (73%) | Faceted (69%) Flat (22%) |

| Platform width | 4 – 10 mm | 4 – 18 mm | 5 – 13 mm |

| Platform thickness | 1 – 3 mm | 1 – 7 mm | 1 – 5 mm |

| Platform/ventral face angles | 111 – 133º | 106 – 128° | 103 – 127 º |

| Platform lip | No lip (42%) Low pro. lip (36%) | No lip (84%) | No lip (82%) |

| Bulb | One pro. bulb (63%) | One pro. bulb (66%) | One pro. bulb (84%) |

| Flake shape | Square (47%) Round (29%) | Square (38%) | Square (42%) Round (24%) |

| Flake side-view | Concave (63%) Straight (35%) | Concave (47%) Straight (42%) | Concave (82%) |

| No. of negatives | 3 – 5 | 3 – 7 | 3 - 5 |

| Dorsal face negatives organization | No standard feature | Convergent (24%) 1 vertical rib (20%) 2 vertical ribs (20%) | Convergent (38%) |

| Cortex | Absent (85%) | Absent (73%) | Absent (87%) |

Table 3. Typical metrical, morphological, and technological features in reductions flakes from a Rioclarense and a Garivaldinense associated site, according to Moreno de Sousa (2019). The range corresponds to standard deviation. Typical features for qualitative attributes were considered when the percentage is larger than 20%.

The selection of the flakes for analysis followed the same procedures of Moreno de Sousa’s (2019) proposal, selecting flakes that are equal or smaller than the reduction negatives maximum length. To seek the technological pattern of the replica’s flakes, descriptive statistics were applied. Statistic tests were not carried out in order to compare the results of the replicated flakes to the archaeological flakes, since these are only the results of a preliminary experiment on Paleoamerican artefacts replication. We will consider the features as ‘similar’ in the following cases:

- When the mass presents a difference of 5 g or less;

- When the length and width present a difference of 5 mm or less;

- When the thickness presents a difference of 1 mm or less;

- When the angles present a difference of 5º or less;

- When the frequency of categories presents a difference of 20% or less;

- When the number of negatives present a difference of 2 or less.

The Rioclarense lesmas replication

Tables 4 and 5 present the blank (See Figure 7) and product (See Figure 8) main features of the replicated lesmas.

| Code | Blank type | Raw material | Mass (g) | Dimensions (mm) | Result |

| RC.Si.8 | Flake | Corumbataí flint | ~ 500 | 135 x 75 x 56 | Successful |

| RC.Si.9 | Flake | Corumbataí flint | ~ 500 | 112 x 93 x 45 | Successful |

| RC.Ar.1 | Flake | Botucatu silicified sandstone | ~ 650 | 143 x 122 x 50 | Successful |

Table 4. Main features of the lesma blanks used in the experiment.

| Attributes | Lesmas features | ||

| RC.Si.8 | RC.Si.9 | RC. Ar.1 | |

| Mass (g) | 114,3 | 209,8 | 257,1 |

| Total length (mm) | 110 | 97 | 135 |

| Maximum width (mm) | 49 | 63 | 60 |

| Maximum thickness (mm) | 24 | 37 | 35 |

| Width/thickness proportions | 2/1 | 1,7/1 | 1,7/1 |

| Reduction negatives organization | Selective and trespassed | Parallels (shaping a vertical central rib) | Parallels (shaping a vertical central rib) |

| Reduction negatives maximum length (mm) | 36 | 43 | 48 |

Table 5. Main features of the replicated lesmas. Selective = No defined order. Trespassed = the negative passes the middle of the artefact.

The reduction flakes from the Corumbataí flint lesmas

The total number of flakes produced during the production of the two flint lesmas is shown in table 6. An interesting thing to notice is that, during the production of the lesmas, there was a false perception that the soft percussion was more used than the hard percussion. The number of the flakes surprised the author.

| Hard percussion | Soft percussion | Total |

| 32 | 32 | 64 |

Table 6. Quantification of flakes produced by each technique.

From the 64 flakes, 12 (19%) of them are bigger than 43 mm (reduction flakes negatives maximum length). The biggest flakes had 65 mm length, indicating that the sampling method proposed by Moreno de Sousa (2019) is a good method for identifying lesmas flakes when no reference collection is available, since more than 80% present the expected size. A total of 15 flakes for each technique were selected, analysed, and compared to the Rioclarense flakes. Tables 7 to 17 present the descriptive statistics for each analysed attribute of the flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 15 | 1,1 | 23,4 | 8,0 | 7,0 |

| Length | 15 | 18 | 43 | 31 | 8 |

| Width | 15 | 16 | 61 | 35 | 13 |

| Thickness | 14 | 4 | 16 | 8 | 4 |

| Platform width | 14 | 5,0 | 27,0 | 14 | 7 |

| Platform thickness | 15 | 1,0 | 10,0 | 5 | 3 |

| Platform/ventral face angle | 15 | 95 | 125 | 110 | 8 |

| Number of negatives in dorsal face | 15 | 0 | 7 | 4 | 2 |

Table 7. Central tendency values of replicated lesmas flakes (hard percussion) quantitative attributes. Cases where n < 15 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 15 | 1,5 | 20,8 | 8,8 | 6,6 |

| Length | 12 | 24 | 50 | 35 | 7 |

| Width | 15 | 20 | 49 | 34 | 10 |

| Thickness | 15 | 3 | 14 | 7 | 3 |

| Platform width | 14 | 3,0 | 17 | 12 | 4 |

| Platform thickness | 15 | 0,1 | 9 | 4 | 2 |

| Platform/ventral face angle | 13 | 100 | 130 | 117 | 10 |

| Number of negatives in dorsal face | 15 | 3 | 10 | 6 | 2 |

Table 8. Central tendency values of replicated lesmas flakes (soft percussion) quantitative attributes. Cases where n < 15 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 30 | 1,1 | 23,4 | 8,4 | 6,7 |

| Length | 27 | 18 | 50 | 33 | 8 |

| Width | 30 | 16 | 61 | 34 | 12 |

| Thickness | 29 | 3 | 16 | 8 | 3 |

| Platform width | 28 | 3 | 27 | 13 | 6 |

| Platform thickness | 30 | 0,1 | 10 | 5 | 3 |

| Platform/ventral face angle | 28 | 95 | 130 | 113 | 10 |

| Number of negatives in dorsal face | 30 | 0 | 10 | 5 | 2 |

Table 9. Central tendency values of replicated lesmas flakes (hard and soft percussion) quantitative attributes. Cases where n < 30 correspond to atypical values (outliers) and broken flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Round | 5 | 33,3 | 3 | 20,0 | 8 | 26,7 |

| Straight | 4 | 26,7 | 3 | 20,0 | 7 | 23,3 |

| Triangle | 2 | 13,3 | 4 | 26,7 | 6 | 20,0 |

| Wing | 2 | 13,3 | 3 | 20,0 | 5 | 16,7 |

| Coma | 2 | 13,3 | 1 | 6,7 | 3 | 10,0 |

| Linear | - | - | 1 | 6,7 | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 10. Frequency (count and percentage) of platform shape categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Faceted | 5 | 33,3 | 11 | 73,3 | 16 | 53,3 |

| Flat | 8 | 53,3 | 3 | 20,0 | 11 | 36,7 |

| Soft cortex | 1 | 6,7 | - | - | 1 | 3,3 |

| Diedral | 1 | 6,7 | - | - | 1 | 3,3 |

| Undefined | - | - | 1 | 6,7 | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 11. Frequency (count and percentage) of platform surface categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| No lip | 13 | 86,7 | 5 | 33,3 | 18 | 60,0 |

| Low prominent lip | 2 | 13,3 | 7 | 46,7 | 9 | 30,0 |

| High prominent lip | - | - | 3 | 20,0 | 3 | 10,0 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 12. Frequency (count and percentage) of platform lip categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| One prominent bulb | 11 | 73,3 | 8 | 53,3 | 19 | 63,3 |

| Non prominent bulb | 2 | 13,3 | 5 | 33,3 | 7 | 23,3 |

| Bulbar flaking | 2 | 13,3 | 2 | 13,3 | 4 | 13,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 13. Frequency (count and percentage) of bulb categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Square | 6 | 40,0 | 6 | 40,0 | 12 | 40,0 |

| Round | 3 | 20,0 | 2 | 13,3 | 5 | 16,7 |

| Undefined | 1 | 6,7 | 3 | 20,0 | 4 | 13,3 |

| Blade | - | - | 3 | 20,0 | 3 | 10,0 |

| Pentagonal | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Triangle | 2 | 13,3 | - | - | 2 | 6,7 |

| Inverse triangle | 2 | 13,3 | - | - | 2 | 6,7 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 14. Frequency (count and percentage) of flake shape categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Concave | 9 | 60,0 | 11 | 73,3 | 20 | 66,7 |

| Straight | 5 | 33,3 | 3 | 20,0 | 8 | 26,7 |

| Convex | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 15. Frequency (count and percentage) of flake side-view categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Convergent | 2 | 13,3 | 7 | 46,7 | 9 | 30,0 |

| 1 vertical rib | 5 | 33,3 | 4 | 26,7 | 9 | 30,0 |

| Y shape | 2 | 13,3 | 1 | 6,7 | 3 | 10,0 |

| Flat | 2 | 13,3 | - | - | 2 | 6,7 |

| 2 vertical ribs | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| 2 vertical + 1 horizontal rib | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Invers Y shape | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| V shape | 1 | 6,7 | - | - | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 16. Frequency (count and percentage) of organization of dorsal face negatives categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Absent | 14 | 93,3 | 14 | 93,3 | 28 | 93,3 |

| Less than 50% | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 17. Frequency (count and percentage) of cortex presence categories in replicated lesmas flakes. Table 18 presents the general features of the lesmas flakes replicas.

| Attributes | Hard percussion | Soft percussion | Both techniques |

| Mass | 1,0 – 15,0 g | 2,2 – 15,4 | 1,7 – 15,1 g |

| Total length | 23 – 39 mm | 28 – 32 mm | 25 – 41 mm |

| Maximum width | 27 – 48 mm | 24 – 44 mm | 22 – 46 mm |

| Maximum thickness | 4 – 12 mm | 4 – 10 mm | 5 – 11 mm |

| Platform shape | Round (33%) Straight (27%) | Triangle (27%) Round (20%) Straight (20%) Wing (20%) | Round (27%) Straight (23%) Triangle (20%) |

| Platform surface | Flat (53%) Faceted (33%) | Faceted (73%) | Faceted (53%) Flat (37%) |

| Platform width | 7 – 21 mm | 8 – 16 mm | 7 – 19 mm |

| Platform thickness | 2 – 8 mm | 2 – 6 mm | 2 – 8 mm |

| Platform/ventral face angles | 102 – 118º | 107 – 128º | 103 – 123º |

| Platform lip | No lip (87%) | Low pro. lip (47%) No lip (33%) High pro. lip. (20%) | No lip (63%) High pro. lip (23%) |

| Bulb | One pro. bulb (73%) | One pro. bulb (73%) Non pro. bulb (33%) | One pro. bulb (63%) Non pro. bulb (23%) |

| Flake shape | Square (40%) Round (20%) | Square (40%) Undefined (20%) | Square (40%) |

| Flake side-view | Concave (60%) Straight (33%) | Concave (73%) Straight (20%) | Concave (67%) Straight (27%) |

| No. of negatives | 2 – 6 | 4 – 8 | 3 – 7 |

| Dorsal face negatives organization | 1 vert. rib. (33%) | Convergent (47%) 1 vert. rib. (27%) | Convergent (30%) 1 vert. rib. (30%) |

| Cortex | Absent (93%) | Absent (93%) | Absent (93%) |

Table 18. Typical metrical, morphological, and technological features in reduction flakes of Rioclarense lesmas flakes and replicas (divided by technique category). The range corresponds to standard deviation. Typical features for qualitative attributes were considered when percentage is bigger than 20%. Replicas’ features presenting the typical Alice Boer flake features are bolded, while the ones presenting Caetetuba flake features are underlined.

Compared to the Rioclarense typical flakes from Alice Boer site, where flint is the most frequent raw material for lesmas, the lesmas reduction flakes present several similarities. However, similarities with the Caetetuba flakes are also observable, but less frequent.

The reduction flakes from the Botucatu silicified sandstone lesmas

The total number of flakes produced during the production of the silicified sandstone lesma is shown in table 19. Unlike what happened with the flint lesmas production, the sandstone lesma production had much more soft percussion application, and it is confirmed in the flake counts.

| Hard percussion | Soft percussion | Total |

| 8 | 31 | 39 |

Table 19. Quantification of flakes produced by each technique.

Similar to what happened to the flint lesmas flakes, only 18% of the flakes are bigger than expected when compared to the lesmas maximum negatives length, corresponding to 7 soft percussion flakes. All the 8 hard percussion flakes and 15 of the soft percussion flakes were analyzed. Tables 20 to 30 present the descriptive statistics for each analyzed attribute of the silicified sandstone flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 8 | 1,9 | 7,1 | 3,9 | 1,9 |

| Length | 8 | 16 | 36 | 26 | 6 |

| Width | 8 | 20 | 35 | 27 | 5 |

| Thickness | 8 | 6 | 12 | 8 | 2 |

| Platform width | 8 | 0,1 | 27 | 17 | 8 |

| Platform thickness | 7 | 0,1 | 7 | 5 | 2 |

| Platform/ventral face angle | 6 | 100 | 115 | 108 | 5 |

| Number of negatives in dorsal face | 8 | 2 | 6 | 3 | 1 |

Table 20. Central tendency values of replicated lesmas flakes (hard percussion) quantitative attributes. Cases where n < 8 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 12 | 1,1 | 11,5 | 4,9 | 3,4 |

| Length | 13 | 16 | 48 | 30 | 9 |

| Width | 12 | 18 | 42 | 30 | 6 |

| Thickness | 15 | 3 | 13 | 8 | 3 |

| Platform width | 15 | 7 | 25 | 13 | 6 |

| Platform thickness | 15 | 2 | 7 | 4 | 2 |

| Platform/ventral face angle | 15 | 100 | 135 | 119 | 9 |

| Number of negatives in dorsal face | 14 | 3 | 7 | 4 | 1 |

Table 21. Central tendency values of replicated lesmas flakes (soft percussion) quantitative attributes. Cases where n < 8 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 20 | 1,1 | 11,5 | 4,5 | 2,9 |

| Length | 21 | 16 | 48 | 29 | 8 |

| Width | 20 | 18 | 42 | 29 | 6 |

| Thickness | 23 | 3 | 13 | 8 | 3 |

| Platform width | 23 | 0,1 | 27 | 14 | 7 |

| Platform thickness | 22 | 0,1 | 7 | 4 | 2 |

| Platform/ventral face angle | 21 | 100 | 135 | 115 | 10 |

| Number of negatives in dorsal face | 22 | 2 | 7 | 4 | 1 |

Table 22. Central tendency values of replicated lesmas flakes (both techniques) quantitative attributes. Cases where n < 23 correspond to atypical values (outliers) and broken flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Straight | 1 | 12,5 | 6 | 40,0 | 7 | 30,4 |

| Round | 3 | 37,5 | 2 | 13,3 | 5 | 21,7 |

| Coma | 1 | 12,5 | 3 | 20,0 | 4 | 17,4 |

| Wing | - | - | 3 | 20,0 | 3 | 13,0 |

| Triangle | 1 | 12,5 | 1 | 6,7 | 2 | 8,7 |

| Linear | 1 | 12,5 | - | - | 1 | 4,3 |

| Dot | 1 | 12,5 | - | - | 1 | 4,3 |

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 23. Frequency (count and percentage) of platform shape categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Faceted | 3 | 37,5 | 8 | 53,3 | 11 | 47,8 |

| Flat | 3 | 37,5 | 7 | 46,7 | 10 | 43,5 |

| Diedral | 2 | 25,0 | - | - | 2 | 8,7 |

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 24. Frequency (count and percentage) of platform surface categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| No lip | 7 | 87,5 | 12 | 80,0 | 19 | 82,6 |

| High prominent lip | 1 | 12,5 | 1 | 6,7 | 2 | 8,7 |

| Low prominent lip | - | - | 2 | 13,3 | 2 | 8,7 |

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 25. Frequency (count and percentage) of platform lip categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| One prominent lip | 6 | 75,0 | 11 | 73,3 | 17 | 73,9 |

| Non prominent bulb | 1 | 12,5 | 3 | 20,0 | 4 | 17,4 |

| Double bulb | - | - | 1 | 6,7 | 1 | 4,3 |

| Bulbar flaking | 1 | 12,5 | 1 | 4,3 | ||

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 26. Frequency (count and percentage) of bulb categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Square | 1 | 12,5 | 7 | 46,7 | 8 | 34,8 |

| Pentagonal | - | - | 7 | 46,7 | 7 | 30,4 |

| Round | 5 | 62,5 | - | - | 5 | 21,7 |

| Inverse triangle | 1 | 12,5 | - | - | 2 | 8,7 |

| Triangle | 1 | 12,5 | 1 | 6,7 | 1 | 4,3 |

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 27. Frequency (count and percentage) of flake shape categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Concave | 6 | 75,0 | 11 | 73,3 | 17 | 73,9 |

| Convex | 1 | 12,5 | 2 | 13,3 | 3 | 13,0 |

| Straight | 1 | 12,5 | 2 | 13,3 | 3 | 13,0 |

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 28. Frequency (count and percentage) of flake side-view categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| 2 vertical ribs | 2 | 25,0 | 3 | 20,0 | 5 | 21,7 |

| Inverse Y shape | 2 | 25,0 | 3 | 20,0 | 5 | 21,7 |

| 1 vertical rib | 1 | 12,5 | 3 | 20,0 | 4 | 17,4 |

| Y shape | 1 | 12,5 | 2 | 13,3 | 3 | 13,0 |

| Convergent | - | - | 2 | 13,3 | 2 | 8,7 |

| 2 horizontal ribs | - | - | 1 | 6,7 | 1 | 4,3 |

| Flat | 1 | 12,5 | - | - | 1 | 4,3 |

| T shape | - | - | 1 | 6,7 | 1 | 4,3 |

| X shape | 1 | 12,5 | - | - | 1 | 4,3 |

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 29. Frequency (count and percentage) of organization of the dorsal face negatives categories in replicated lesmas flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Absent | 8 | 100,0 | 15 | 100,0 | 23 | 100,0 |

| Total | 8 | 100 | 15 | 100 | 23 | 100 |

Table 29. Frequency (count and percentage) of cortex presence categories in replicated lesmas flakes.

| Attributes | Hard percussion | Soft percussion | Both techniques | ||

| Mass | 2,0 – 5,8 g | 1,5 – 8,3 g | 1,6 – 7,4 g | ||

| Total length | 20 – 32 mm | 21 – 39 mm | 21 – 37 mm | ||

| Maximum width | 22 – 32 mm | 24 – 36 mm | 23 – 35 mm | ||

| Maximum thickness | 6 – 10 mm | 5 – 12 mm | 5 – 11 mm | ||

| Platform shape | Round (38%) | Straight (40%) Coma (20%) Wing (20%) | Straight (20%) Round (22%) | ||

| Platform surface | Faceted (38%) Flat (38%) Diedral (25%) | Faceted (53%) Flat (47%) | Faceted (48%) Flat (44%) | ||

| Platform width | 9 – 25 mm | 7 – 19 mm | 7 – 21 mm | ||

| Platform thickness | 3 – 7 mm | 2 – 6 | 2 – 6 mm | ||

| Platform/ventral face angles | 103 – 113º | 110 – 128º | 105 – 125 º | ||

| Platform lip | No lip (88%) | No lip (80%) | No lip (83%) | ||

| Bulb | One pro. bulb (75%) | One pro. bulb. (74%) No pro. bulb. (20%) | One pro. bulb (74%) | ||

| Flake shape | Round (62%) | Square (47%) Pentagonal (47%) | Square (35%) Pentagonal (30%) Round (22%) | ||

| Flake side-view | Concave (75%) | Concave (73%) | Concave (74%) | ||

| No. of negatives | 2 – 3 | 3 – 5 | 3 – 5 | ||

| Dorsal face negatives organization | 2 vert. ribs (25%) Inverse Y shape (25%) | 2 vert. ribs (20%) Inverse Y shape (20%) 1 vert. rib (20%) | 2 vert. ribs (22%) Inverse Y shape (22%) | ||

| Cortex | Absent (100%) | Absent (100%) | Absent (100%) | ||

Table 31. Typical metrical, morphological, and technological features in reduction flakes of Rioclarense lesmas flakes and replicas (divided by technique category). The range corresponds to standard deviation. Typical features for qualitative attributes were considered when percentage is larger than 20%. Replicas’ features presenting the typical Alice Boer flake features are bolded, while the ones presenting Caetetuba flake features are underlined.

When compared to the Caetetuba site flakes, where most lesmas are made of Botucatu silicified sandstone, very few similarities are found. But when compared to the Alice Boer site flint flakes, many similarities were found. It was expected that sandstone replicas would be similar to sandstone archaeological flakes, but instead they are similar to the flint ones. This led to questioning if this was caused by the major application of hard percussion. But more systematic experiments must be carried out before any conclusions on what technical difference caused this difference can be made.

The Rioclarense points replication

The Corumbataí flint points

Tables 32 and 33 present the blank (See Figure 9) and product (See Figure 10) main features of the replicated Rioclarense points. In the cases the replicas were not finished, the reasons for interruption were described.

| Code | Blank type | Mass (g) | Dimensions (mm) | Result |

| RC.Si.1 | Flake fragment | 28,8 | 69 x 43 x 12 | Successful |

| RC.Si.2 | Flake | 173,6 | 96 x 95 x 15 | Successful |

| RC.Si.3 | Natural | 145,9 | 90 x 46 x 23 | Broken preform |

| RC.Si.4 | Flake | 194,9 | 86 x 112 x 30 | Successful |

| RC.Si.5 | Natural | 69,1 | 66 x 47 x 14 | Successful |

| RC.Si.6 | Natural | 89,5 | 73 x 55 x 15 | Broken preform |

| RC.Si.7 | Natural | 137,6 | 95 x 70 x 14 | Successful |

Table 32. Main features of the Rioclarense point blanks used in the experiment.

| Attributes | Rioclarense point replicas features | ||||

| RC.Si.1 | RC.Si.2 | RC.Si.4 | RC.Si.5 | RC.Si.7 | |

| Mass | 6,1 g | 7,9 g | 5,3 g | 5,1 g | 4,4 g |

| Total length (mm) | 39 mm | 50 mm | 41 mm | 43 mm | 46 mm |

| Max. width (mm) | 22 mm | 28 mm | 23 mm | 23 mm | 19 mm |

| Max. thickness (mm) | 8 mm | 8 mm | 7 mm | 7 mm | 6 mm |

| Width/thick. prop. | 2,7/1 | 3,5/1 | 3,3/1 | 3,3/1 | 3,2/1 |

| Body Length | 22 mm | 31 mm | 30 mm | 33 mm | 26 mm |

| Stem Length | 17 mm | 19 mm | 11 mm | 10 mm | 20 mm |

| Active Edges Length | 25 mm | 33 mm | 32 mm | 35 mm | 29 mm |

| Wings Width | 22 mm | 28 mm | 23 mm | 23 mm | 28 mm |

| Neck Width | 15 mm | 14 mm | 11 mm | 12 mm | 11 mm |

| Stem Width | 14 mm | 13 mm | 10 mm | 11 mm | 10 mm |

| Body Thickness | 6 mm | 5 mm | 7 mm | 5 mm | 6 mm |

| Neck Thickness | 8 mm | 8 mm | 7 mm | 7 mm | 6 mm |

| Stem Thickness | 6 mm | 6 mm | 5 mm | 5 mm | 5 mm |

| Active edges angle | 60 º | 60 º | 60º | 45º | 60º |

| Body shape | Triangle | Triangle | Triangle | Triangle | Triangle |

| Active Edges Lineation | Straight | Straight | Straight | Straight | Straight |

| Wings Shape | Straight | Straight | Straight | Straight | Straight |

| Neck lineation | Obtuse | Obtuse | Obtuse | Obtuse | Obtuse |

| Stem shape | Ovalate | Ovalate | Ovalate | Ovalate | Ovalate |

| Body section shape | Elliptical | Elliptical | Elliptical | Elliptical | Elliptical |

| Stem section shape | Elliptical | Elliptical | Elliptical | Elliptical | Elliptical |

| Blank type | Not definable | Not definable | Not definable | Not definable | Not definable |

| Reduction method | Bifacial | Bifacial | Bifacial | Bifacial | Bifacial |

| Reduction technique | Percussion | Percussion | Percussion | Percussion | Percussion + pressure |

| Retouch method | Bifacial | Bifacial | Bifacial | Bifacial | Bifacial |

| Retouch technique | Pressure | Pressure | Pressure | Pressure | Pressure |

| Body negatives organization | Selective and trespassed | Selective and trespassed | Parallels (shaping a vert. rib) | Selective and trespassed | Parallels (shaping a vert. rib) |

| Stem negatives organization | Parallels (shaping a vert. rib) | Parallels (shaping a vert. rib) | Parallels (shaping a vert. rib) | Parallels (shaping a vert. rib) | Parallels (shaping a vert. rib) |

Table 33. Main features of the replicated Rioclarense points. Underlined features do not correspond to accurate Rioclarense point feature patterns. Selective = No defined order. Trespassed = the negative passes the middle of the artefact.

All the natural blanks were plaque shaped pebbles. Curiously, the fossilized oil in these plaques present a glassier configuration, with a higher quality for knapping and especially, pressure flaking. The production of RC.Si.3 and RC.Si.6 replicas was interrupted due internal fractures of the blanks that expanded after a percussion, breaking the preform apart. The RC.Si.5 blank broke in the first knap, so the biggest part was used to finish the point.

The few metric differences between the Rioclarense points and the replicas are not significant, since they are only 1 mm bigger. In general, the replicas are very accurate, and the replicated flakes are expected to be very similar to the archaeological ones.

The reduction flakes from the Rioclarense points

The total amount of flakes produced during the Rioclarense point production is shown in table 34. Flakes with broken platforms were excluded from the counting and discarded due the impossibility of platform, lip, and bulb analysis.

| Hard percussion | Soft percussion | Pressure | Undefined | Total |

| 113 | 176 | 59 | 23 | 371 |

Table 34. Quantification of flakes produced by each technique. Undefined = flakes that were not collected in the moment of their removal.

Even though the volume of flakes is bigger than the detritus, detritus are more numerous. However, it is not possible to accurate quantify them, since the small size of several pieces of detritus make it hard to control quantification.

Flakes of less than 15 mm were not considered for analysis, since this was the smallest flake size in Rioclarense analysed flakes by Moreno de Sousa (2019). Flakes of more than 50 mm were not analysed, since this was the maximum length of the Rioclarense artefact negatives. No flake obtained by pressure flaking was bigger than 15 mm. 15 flakes were selected from each percussion technique. Tables 35 to 45 present the descriptive statistics for each analysed attribute of the flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 13 | 0,6 | 5,4 | 2,1 | 1,4 |

| Length | 15 | 17 | 42 | 25 | 8 |

| Width | 15 | 18 | 50 | 29 | 10 |

| Thickness | 13 | 2 | 8 | 4 | 2 |

| Platform width | 15 | 0,1 | 26,0 | 13 | 8 |

| Platform thickness | 15 | 0,1 | 7,0 | 4 | 2 |

| Platform/ventral face angle | 14 | 95 | 125 | 107 | 10 |

| Number of negatives in dorsal face | 15 | 0 | 6 | 3 | 2 |

Table 35. Central tendency values of replicated Rioclarense points flakes (hard percussion) quantitative attributes. Cases where n < 15 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 14 | 0,6 | 6,5 | 2,1 | 1,5 |

| Length | 14 | 19 | 43 | 27 | 7 |

| Width | 15 | 19 | 41 | 27 | 7 |

| Thickness | 14 | 2 | 7 | 4 | 1 |

| Platform width | 14 | 5 | 17 | 9 | 3 |

| Platform thickness | 14 | 1 | 5 | 2 | 1 |

| Platform/ventral face angle | 15 | 100 | 125 | 112 | 8 |

| Number of negatives in dorsal face | 15 | 0 | 8 | 4 | 2 |

Table 36. Central tendency values of replicated Rioclarense points flakes (soft percussion) quantitative attributes. Cases where n < 15 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 27 | 0,6 | 6,5 | 2,1 | 1,4 |

| Length | 29 | 17 | 43 | 26 | 7 |

| Width | 30 | 18 | 50 | 28 | 8 |

| Thickness | 27 | 2 | 8 | 4 | 1 |

| Platform width | 29 | 0,1 | 26 | 11 | 7 |

| Platform thickness | 29 | 0,1 | 7 | 3 | 2 |

| Platform/ventral face angle | 29 | 95 | 125 | 110 | 9 |

| Number of negatives in dorsal face | 30 | 0 | 8 | 4 | 2 |

Table 37. Central tendency values of replicated Rioclarense points flakes (hard and soft percussion) quantitative attributes. Cases where n < 30 correspond to atypical values (outliers) and broken flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Straight | 4 | 26,7 | 6 | 40,0 | 10 | 33,3 |

| Wing | 5 | 33,3 | 3 | 20,0 | 8 | 26,7 |

| Coma | 2 | 13,3 | 4 | 26,7 | 6 | 20,0 |

| Triangle | 2 | 13,3 | 1 | 6,7 | 3 | 10,0 |

| Round | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Dot | 1 | 6,7 | - | - | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 38. Frequency (count and percentage) of platform shape categories in replicated Rioclarense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Faceted | 3 | 20,0 | 12 | 80,0 | 15 | 50,0 |

| Flat | 4 | 26,7 | 3 | 20,0 | 7 | 23,3 |

| Cortical | 5 | 33,3 | - | - | 5 | 16,7 |

| Diedral | 2 | 13,3 | - | - | 2 | 6,7 |

| Undefined | 1 | 6,7 | - | - | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 39. Frequency (count and percentage) of platform surface categories in replicated Rioclarense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| No lip | 14 | 93,3 | 7 | 46,7 | 21 | 70,0 |

| Low prominent lip | 1 | 6,7 | 8 | 53,3 | 9 | 30,0 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 40. Frequency (count and percentage) of platform lip categories in replicated Rioclarense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| One prominent bulb | 13 | 86,7 | 10 | 66,7 | 23 | 76,7 |

| Low prominent bulb | 1 | 6,7 | 3 | 20,0 | 4 | 13,3 |

| Bulbar flaking | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Double bulb | - | - | 1 | 6,7 | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 41. Frequency (count and percentage) of bulb categories in replicated Rioclarense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Square | 6 | 40,0 | 7 | 46,7 | 13 | 43,3 |

| Inverse triangle | 5 | 33,3 | 3 | 20,0 | 8 | 26,7 |

| Lozenge | 1 | 6,7 | 2 | 13,3 | 3 | 10,0 |

| Triangle | 1 | 6,7 | 2 | 13,3 | 3 | 10,0 |

| Round | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Undefined | 1 | 6,7 | - | - | 1 | 6,7 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 42. Frequency (count and percentage) of flake shape categories in replicated Rioclarense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Concave | 9 | 60,0 | 12 | 80,0 | 21 | 70,0 |

| Straight | 6 | 40,0 | 3 | 20,0 | 9 | 30,0 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 43. Frequency (count and percentage) of flake side-view categories in replicated Rioclarense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Convergent | 4 | 26,7 | 6 | 40,0 | 10 | 33,3 |

| 2 vertical ribs | 3 | 20,0 | - | - | 3 | 10,0 |

| 1 horizontal rib | 2 | 13,3 | 3 | 20,0 | 5 | 16,7 |

| 1 vertical rib | 2 | 13,3 | 2 | 13,3 | 4 | 13,3 |

| 2 horizontal rib | - | - | 1 | 6,7 | 1 | 3,3 |

| 3 horizontal rib | - | - | 1 | 6,7 | 1 | 3,3 |

| 2 vertical + 1 horizontal ribs | 1 | 6,7 | - | - | 1 | 3,3 |

| V shape | 1 | 6,7 | - | - | 1 | 3,3 |

| Y shape | 1 | 6,7 | 1 | 6,7 | 2 | 6,7 |

| Inverse Y shape | - | - | 1 | 6,7 | 1 | 3,3 |

| Flat | 1 | 6,7 | - | - | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 44. Frequency (count and percentage) of organization of dorsal face negatives categories in replicated Rioclarense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Absent | 10 | 66,7 | 10 | 66,7 | 20 | 66,7 |

| > 50% | 3 | 20,0 | 1 | 6,7 | 4 | 13,3 |

| < 50% | 1 | 6,7 | 4 | 26,7 | 5 | 16,7 |

| Complete | 1 | 6,7 | - | - | 1 | 3,3 |

| Total | 15 | 100 | 15 | 100 | 30 | 100 |

Table 45. Frequency (count and percentage) of cortex presence categories in replicated Rioclarense point flakes.

| Attributes | Hard percussion | Soft percussion | Both techniques |

| Mass | 0,7 – 3,5 g | 0,6 – 3,6 mm | 0,7 – 3,5 mm |

| Total length | 17 – 33 mm | 20 – 34 mm | 19 – 33 mm |

| Maximum width | 19 – 39 mm | 20 – 34 mm | 20 – 36 mm |

| Maximum thickness | 2 – 6 mm | 3 – 5 mm | 3 – 5 mm |

| Platform shape | Wing (33%) Straight (27%) | Straight (40%) Coma (27%) Wing (20%) | Straight (33%) Wing (27%) Coma (20%) |

| Platform surface | Cortical (33%) Flat (27%) Faceted (20%) | Faceted (80%) Flat (20%) | Faceted (50%) Flat (23%) |

| Platform width | 5 – 21 mm | 6 – 12 mm | 4 – 18 mm |

| Platform thickness | 2 – 6 mm | 1 – 3 mm | 1 – 5 mm |

| Platform/ventral face angles | 97 – 117º | 104 – 120º | 101 – 119º |

| Platform lip | No lip (93%) | Low pro. lip (53%) No lip (47%) | No lip (70%) Low pro. lip (30%) |

| Bulb | One pro. bulb (87%) | One pro. bulb (67%) Non pro. bulb (20%) | One pro. bulb (77%) |

| Flake shape | Square (40%) Inverse triangle (33%) | Square (47%) Inverse triangle (20%) | Square (43%) Inverse triangle (27%) |

| Flake side-view | Concave (60%) Straight (40%) | Concave (80%) Straight (20%) | Concave (70%) Straight (30%) |

| No. of negatives | 1 – 5 | 2 – 6 | 2 – 6 |

| Dorsal face negatives organization | Convergent (27%) 2 vertical ribs (20%) | Convergent (40%) One vertical rib (20%) | Convergent (33%) |

| Cortex | Absent (67%) > 50% (20%) | Absent (67%) < 50% (27%) | Absent (67%) |

Table 46. presents the standard features of the replicated Rioclarense point flakes. Table 46. Typical metrical, morphological, and technological features in reduction flakes of Rioclarense lesmas flakes and replicas (divided by technique category). The range corresponds to standard deviation. Typical features for qualitative attributes were considered when percentage is bigger than 20%. Replicas’ features presenting the typical Alice Boer flake features are bolded, while the ones presenting Caetetuba flake features are underlined.

In comparison to the Alice Boer site flakes, few similarities were found. The same can be said when comparing to the Caetetuba site flakes.

The Garivaldinense points replication

The Botucatu silicified sandstone points

Tables 47 and 48 present the blank (See Figure 11) and product (See Figure 12) main features of the replicated Rioclarense points. In the cases the replicas where not finished, the reasons for interruption were described.

| Code | Blank type | Mass (g) | Dimensions (mm) | Result | ||

| Ga.Ar.1 | Flake | 51,9 | 55 x 66 x 17 | Successful | ||

| Ga.Ar.2 | Flake | 41,2 | 49 x 72 x 14 | Broken preform | ||

| Ga.Ar.3 | Flake | 73,7 | 77 x 64 x 14 | Preform | ||

| Ga.Ar.4 | Flake | 39,7 | 42 x 61 x 15 | Successful | ||

| Ga.Ar.5 | Flake | 16,2 | 37 x 52 x 06 | Successful | ||

Table 47. Main features of the Garivaldinense point blanks used in the experiment.

| Attributes | Garivaldinense point replicas features | ||

| Ga.Ar.1 | Ga.Ar.4 | Ga.Ar.5 | |

| Mass | 6,4 g | 7,2 g | 5,3 g |

| Total length (mm) | 44 mm | 44 mm | 35 mm |

| Max. width (mm) | 24 mm | 25 mm | 21 mm |

| Max. thickness (mm) | 7 mm | 7 mm | 8 mm |

| Width/thick. prop. | 3,4/1 | 3,6/1 | 2,6/1 |

| Body Length | 27 mm | 28 mm | 21 mm |

| Stem Length | 17 mm | 16 mm | 14 mm |

| Active Edges Length | 29 mm | 30 mm | 24 mm |

| Wings Width | 24 mm | 25 mm | 21 mm |

| Neck Width | 15 mm | 17 mm | 12 mm |

| Stem Width | 15 mm | 16 mm | 14 mm |

| Body Thickness | 5 mm | 6 mm | 7 mm |

| Neck Thickness | 6 mm | 7 mm | 8 mm |

| Stem Thickness | 7 mm | 5 mm | 6 mm |

| Active edges angle | 55º | 60º | 65º |

| Body shape | Triangle | Triangle | Triangle |

| Active Edges Lineation | Straight | Straight | Straight |

| Wings Shape | Straight | Straight | Straight |

| Neck lineation | Obtuse | Obtuse | Obtuse |

| Stem shape | Straight | Bifurcate | Straight |

| Body section shape | Elliptical | Elliptical | Elliptical |

| Stem section shape | Elliptical | Bielliptical | Elliptical |

| Blank type | Flake | Undefined | Flake |

| Reduction method | Bifacial | Bifacial | Absent |

| Reduction technique | Percussion | Percussion | Absent |

| Retouch method | Bifacial | Bifacial | Bifacial |

| Retouch technique | Pressure | Pressure | Pressure |

| Body negatives organization | Selective and trespassed | Selective and trespassed | Only retouches |

| Stem negatives organization | Only retouches | Only retouches | Only retouches |

Table 48. Main features of the replicated Garivaldinense points. Underlined features do not correspond to accurate Garivaldinense points features pattern. Selective = No defined order. Trespassed = the negative passes the middle of the artefact.

All blanks were flakes produced by generic debitage. The Ga.Ar.2 piece could not be finished, since it broke during the bifacial reduction. The Ga.Ar.3 preform was abandoned due its excessive thickness and several negatives that ended with step fractures that did not allow preform thinning reduction. The Ga.Ar.5 point would have been considered a successful replication, but one of the stem edges couldn’t be retouched, since the angle for pressure flaking was lost. This did not affect the sampling of flakes for analysis. The few features that were not accurately replicated are metrical. Two replicas got too thin for Garivaldinense standards.

The reduction flakes from the Garivaldinense points

An interesting factor on the flakes from the Garivaldinense experiment is that a lot of flakes broke during the knapping process. Even though they were successfully removed, they were broken in two parts (distal and proximal). This phenomenon was not observed during the replication of the Botucatu silicified sandstone lesma. This suggests that, even though the raw material is from the same geological formation, there is a huge diversity in their constitution in different areas which certainly reflects on the flaking quality.

The total amount of flakes produced during the Rioclarense point production is shown in table 49. Flakes with broken platforms were excluded from the counting and discarded due the impossibility of platform, lip, and bulb analyses. It was not possible to refit all broken flakes, so these specimens were discarded from the analysed sample.

| Hard percussion | Soft percussion | Pressure | Total |

| 15 | 63 | 58 | 136 |

Table 49. Quantification of flakes produced by each technique. Undefined = flakes that were not collected in the moment of their removal.

Only one flake exceeded the maximum size of the points, and was not considered for analysis. No flake of less than 10 mm was analysed, since they were also not analysed by Moreno de Sousa (2019) and cannot be compared. This excludes all pressure flakes, since they are all smaller than 10 mm. From the flakes measuring 10 to 44 mm, 15 of each knapping technique were randomly selected and analysed. Tables 50 to 60 present the descriptive statistics for each analysed attribute of the flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 11 | 0,1 | 1,2 | 0,6 | 0,3 |

| Length | 11 | 8 | 15 | 12 | 2 |

| Width | 11 | 11 | 24 | 17 | 4 |

| Thickness | 11 | 1 | 7 | 4 | 2 |

| Platform width | 10 | 3 | 15 | 9 | 4 |

| Platform thickness | 11 | 1 | 7 | 3 | 2 |

| Platform/ventral face angle | 11 | 90 | 125 | 109 | 11 |

| Number of negatives in dorsal face | 11 | 1 | 3 | 2 | 1 |

Table 50. Central tendency values of replicated Garivaldinense point flakes (hard percussion) quantitative attributes. Cases where n < 15 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 13 | 0,3 | 1,4 | 0,8 | 0,4 |

| Length | 14 | 13 | 27 | 18 | 4 |

| Width | 15 | 10 | 26 | 17 | 4 |

| Thickness | 15 | 2 | 5 | 4 | 1 |

| Platform width | 15 | 4 | 15 | 10 | 3 |

| Platform thickness | 15 | 1 | 5 | 3 | 1 |

| Platform/ventral face angle | 15 | 95 | 135 | 119 | 15 |

| Number of negatives in dorsal face | 15 | 1 | 4 | 3 | 1 |

Table 51. Central tendency values of replicated Garivaldinense point flakes (soft percussion) quantitative attributes. Cases where n < 15 correspond to atypical values (outliers) and broken flakes.

| Quantitative attributes | n | Minimum | Maximum | Mean | Standard deviation |

| Mass | 24 | 0,1 | 1,4 | 0,7 | 0,4 |

| Length | 25 | 8 | 27 | 16 | 5 |

| Width | 26 | 10 | 26 | 17 | 4 |

| Thickness | 26 | 1 | 7 | 4 | 1 |

| Platform width | 25 | 3 | 15 | 9 | 4 |

| Platform thickness | 26 | 1 | 7 | 3 | 2 |

| Platform/ventral face angle | 26 | 90 | 135 | 114 | 14 |

| Number of negatives in dorsal face | 26 | 1 | 4 | 3 | 1 |

Table 52. Central tendency values of replicated Garivaldinense point flakes (hard and soft percussion) quantitative attributes. Cases where n < 15 correspond to atypical values (outliers) and broken flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Straight | 4 | 36,4 | 6 | 40,0 | 10 | 38,5 |

| Round | 3 | 27,3 | 5 | 33,3 | 8 | 30,8 |

| Triangle | 2 | 18,2 | 1 | 6,7 | 3 | 11,5 |

| Wing | - | - | 2 | 13,3 | 2 | 7,7 |

| Coma | 2 | 18,2 | - | - | 2 | 7,7 |

| Pentagonal | - | - | 1 | 6,7 | 1 | 3,8 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 53. Frequency (count and percentage) of platform shape categories in replicated Garivaldinense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Faceted | - | - | 13 | 86,7 | 13 | 50,0 |

| Cortical | 6 | 54,5 | 1 | 6,7 | 7 | 26,9 |

| Flat | 4 | 36,4 | 1 | 6,7 | 5 | 19,2 |

| Diedral | 1 | 9,1 | - | - | 1 | 3,8 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 54. Frequency (count and percentage) of platform surface categories in replicated Garivaldinense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| No lip | 10 | 90,9 | 6 | 40,0 | 16 | 61,5 |

| High prominent lip | 1 | 9,1 | 6 | 40,0 | 7 | 26,9 |

| Low prominent lip | - | - | 3 | 20,0 | 3 | 11,5 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 55. Frequency (count and percentage) of platform lip categories in replicated Garivaldinense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| No prominent bulb | 6 | 54,5 | 10 | 66,7 | 13 | 50,0 |

| One prominent bulb | 4 | 36,4 | 5 | 33,3 | 12 | 45,2 |

| Bulbar flaking | 1 | 9,1 | - | - | 1 | 3,8 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 56. Frequency (count and percentage) of bulb categories in replicated Garivaldinense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Square | 5 | 45,5 | 6 | 40,0 | 11 | 42,3 |

| Round | 4 | 36,4 | 1 | 6,7 | 5 | 19,2 |

| Triangle | - | - | 4 | 26,7 | 4 | 15,4 |

| Irregular | - | - | 2 | 13,3 | 2 | 7,7 |

| Horizontal blade | 1 | 9,1 | - | - | 1 | 3,8 |

| Lozenge | - | - | 1 | 6,7 | 1 | 3,8 |

| Pentagonal | - | - | 1 | 6,7 | 1 | 3,8 |

| Inverse triangle | 1 | 9,1 | - | - | 1 | 3,8 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 57. Frequency (count and percentage) of flake shape categories in replicated Garivaldinense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Concave | 4 | 36,4 | 11 | 73,3 | 15 | 57,7 |

| Straight | 6 | 54,5 | 4 | 26,7 | 10 | 38,5 |

| Convex | 1 | 9,1 | - | - | 1 | 3,8 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 58. Frequency (count and percentage) of flake side-view categories in replicated Garivaldinense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Flat | 5 | 45,5 | - | - | 5 | 19,2 |

| 1 vertical rib | 1 | 9,1 | 4 | 26,7 | 5 | 19,2 |

| 2 vertical ribs | - | - | 4 | 26,7 | 4 | 15,4 |

| 1 horizontal rib | 3 | 27,3 | - | - | 3 | 11,5 |

| Inverse Y shape | - | - | 3 | 20,0 | 3 | 11,5 |

| Convergent | - | - | 2 | 13,3 | 2 | 7,7 |

| Y shape | 1 | 9,1 | 1 | 6,7 | 2 | 7,7 |

| 2 vertical + 1 horizontal ribs | - | - | 1 | 6,7 | 1 | 3,8 |

| T shape | 1 | 9,1 | - | - | 1 | 3,8 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 59. Frequency (count and percentage) of organization of dorsal face negatives categories in replicated Garivaldinense point flakes.

| Categories | Hard percussion | Soft percussion | Both techniques | |||

| n | % | n | % | n | % | |

| Absent | 5 | 45,5 | 14 | 93,3 | 19 | 73,1 |

| < 50% | 5 | 45,5 | 1 | 6,7 | 5 | 19,2 |

| > 50% | 1 | 9,1 | - | - | 2 | 7,7 |

| Total | 11 | 100 | 15 | 100 | 26 | 100 |

Table 60. Frequency (count and percentage) of cortex presence categories in replicated Garivaldinense point flakes.

| Attributes | Hard percussion | Soft percussion | Both techniques | ||

| Mass | 0,3 – 0,9 g | 0,4 – 1,2 g | 0,3 – 1,1 g | ||

| Total length | 10 – 14 mm | 14 – 22 mm | 11 – 19 mm | ||

| Maximum width | 13 – 21 mm | 13 – 21 mm | 13 – 21 mm | ||

| Maximum thickness | 2 – 6 mm | 3 – 5 mm | 3 – 5 mm | ||

| Platform shape | Straight (36%) Round (27%) | Straight (40%) Round (33%) | Straight (38%) Round (31%) | ||

| Platform surface | Cortical (54%) Flat (36%) | Faceted (87%) | Faceted (50%) Cortical (27%) | ||

| Platform width | 5 – 13 mm | 7 – 13 mm | 5 – 13 mm | ||

| Platform thickness | 1 – 5 mm | 2 – 4 mm | 1 – 5 mm | ||

| Platform/ventral face angles | 98 – 120 º | 104 – 134º | 100 – 128º | ||

| Platform lip | No lip (91%) | No lip (40%) High pro. lip (40%) Low pro. lip (20%) | No lip (61%) High pro. lip (27%) | ||

| Bulb | No pro. bulb (54%) One pro. bulb (36%) | No pro. bulb (67%) One pro. bulb (33%) | No pro. bulb (50%) One pro. bulb (45%) | ||

| Flake shape | Square (45%) Round (36%) | Square (40%) Round (27%) | Square (42%) | ||

| Flake side-view | Straight (54%) Concave (36%) | Concave (73%) Straight (27%) | Concave (58%) Straight (38%) | ||

| No. of negatives | 1 – 3 | 1 – 3 | 1 – 3 | ||

| Dorsal face negatives organization | Flat (45%) 1 horizontal rib (27%) | 1 vertical rib (27%) 2 vertical ribs (27%) Inverse Y shape (20%) | No standard feature | ||

| Cortex | Absent (45%) < 50% (45%) | Absent (93%) | Absent (73%) | ||

Table 61 presents the standard features of the replicated Garivaldinense point flakes. Table 61. Typical metrical, morphological, and technological features in reduction flakes of Rioclarense lesmas flakes and replicas (divided by technique category). The range corresponds to standard deviation. Typical features for qualitative attributes were considered when percentage is larger than 20%. Replicas’ features presenting the typical Garivaldinense flake features are bolded.

Not many similarities are observable between the archaeological flake and the replicas.

Discussion

The analysis of the Rioclarense and Garivaldinense associated assemblages carried out by Moreno de Sousa (2019) provided a very good technological description of the main technological features of their lesmas, stemmed points and flakes. This article presented the technological features of very accurate replicas of lesmas, Rioclarense points, and Garivaldinense points from those industries, as well as the features of their reduction flakes.

The replicated lesmas reduction flakes presented many similar features to the ones from the Alice Boer site, but few from the Caetetuba site. The replicated Rioclarense points flakes, however, did not present many similarities with any of those sites’ assemblages. It was already expected that the flakes from the points would not be similar to the Caetetuba site, since most flakes of that site were not from stemmed point production. The fact that the flakes from the replicas were similar to the Alice Boer ones in the lesmas replicas cases probably means that the analysed flakes for that site by Moreno de Sousa (2019) were mostly from lesmas production, and not from Rioclarense points production. The difference on the Caetetuba and Alice Boer archaeological flakes, however, is still unclear, but may be the result of different technological strategies of lesmas production.

There are no other sites associated with the Rioclarense Industry that have had their flakes analysed in that same systematic protocol. The Itaparica Industry, also known by the large presence of limaces, never had its flakes analysed in a similar technological protocol, except for a study on the Gruta das Araras site provided by Moreno de Sousa (2016). However, the data provided in that study reveals almost no similarities with those presented in this article. It seems that this experiment replicated in a very accurate way the lesmas technology from Alice Boer site, but not from other currently recognized archaeological sites. It is suggested that more flakes from Itaparica and Rioclarense associated sites need to be analysed in order to better understand the technological diversity of lesmas production that cannot be observed by the final product analysis.

In the Garivaldinense replication, few similarities between the replicated and the archaeological flakes were found. Some technological differences could be related to the raw material constitution (that presents local variation), like the bulb and the lip. But other features, like the negatives in the dorsal face of the flakes, are probably different due the reduction sequence strategies – possibly because the author has more familiarity at working with better quality raw materials for flaking, like flint, and tried to apply similar technological strategies in a more difficult raw material. Even though the replicated points are very similar to the archaeological ones, the comparison between the archaeological flakes and the replicated ones indicate that different production strategies may lead to identical products. These results also indicate that the technological analysis of the artefacts is not enough to describe the lithic industries technology.

Experimental archaeology is not a consolidated research line in Brazil (and most of South America). There are few studies that tried to understand lithic industries through replication experiments. It is suggested (and expected) that more research like this is carried out in the near future, combining lithic technology and experimental archaeology – or as Nami (2018) suggested, ‘experimental lithic technology’ research. Even though this is a first attempt to better understand the Brazilian Paleoamerican cultures, the obtained results provided very interesting information that lead us to important discussions on lithic technology.

The experiments indicate that there are few direct relationships between artefact shapes and technology. One set of flaking methods and techniques makes it possible to produce stemmed points with different morphological aspects. And very similar artefacts can be produced by different sets of production methods and techniques. The Garivaldinense industry is a good example that morphological and technological choices are not necessarily related due the technological diversity presented in the Garivaldinense type points.

A more coherent relation is the one between technology and raw material flaking quality. More than 90% of Brazilian Paleoamerican lithic assemblages are defined by the use of silicified sandstone (Morais, 1983; Araujo and Pugliese Jr., 2009), due its good quality and abundance in Eastern South America. It is notable that flint is the preferable raw material for stemmed points, especially the thinner ones, even in sites where no flint sources are known (Moreno de Sousa, 2019). The experiments demonstrated that South American silicified sandstones are rarely as good for bifacial thinning reduction as most South American flints. This could be a reason for Garivaldinense points being relatively thicker (considering the maximum width and thickness proportion in points) than the other Eastern South American Paleoamerican points. However, the results of this experiment proved that they could be thinner.

This experiment also demonstrated that the replication of lithic artefacts may provide not only artefact replicas to be used as reference collection, but provide good flakes for the same purpose, but only in the cases where there is evidence supporting the replicated flakes as being similar to the archaeological ones. In this study the experiments on the Rioclarense Industry provided a good flakes reference collection, while the Garivaldinense experiments did not. But Garivaldinense flakes can still be provided after more repetitions of the experiment.

The ideal scenario would be the one where we already have reference collections of flakes, or reference tables, that we could access in order to identify the flake categories in different lithic assemblages. This suggests that the analysis of the flakes would only be carried out after the analysis and replication of the artefacts (products) is carried out.

We noticed that the soft percussion has a bigger tendency to create prominent lips in the flakes of Corumbataí flint and Botucatu silicified sandstone than hard percussion. Still, only in half of the cases of soft percussion was the prominent lip is created. The prominence of the bulb, however, seems to be related to the raw material constitution, and not to the percussion technique, since most of the Corumbataí flint produced prominent bulbs in both techniques, while the Botucatu silicified sandstone flakes from both techniques did not present prominent bulbs.

One final point that needs discussion is related to the similarity between the lesmas and bifacial points flakes technological features. When we look to the replicated flakes from the Rioclarense Industry, we can find similarities in the standard features of both points (bifacial technology) and lesmas (unifacial technology), like the platform, flake side-view and the negatives organization in the dorsal face. It might seem logical to associate flakes that present faceted platforms (platforms that present small bulb scars), concave side-views, and convergent negatives to bifaces. However, these features may also be all simultaneously present in lesmas reduction flakes. These features are especially common when the lesma reduction is characterized by the removal of long flakes that trespass the middle of the artefact in order to make it thinner. When this is the case, more obtuse angles between the platform and the flaking surface are needed in order to obtain long flakes. These angles are created by the facetage – that creates faceted platforms. The flakes will be mainly concave in these cases. It is important to remember that the plano-convex cross-section shape is one of the main attributes for lesmas definition. And the few negatives that might be identified in the planar face are only related to the facetage process – this is important to consider before interpreting these small scars in the planar face as retouching.