The content is published under Creative Commons Attribution 4.0 International license

Reviewed Article:

Experiments and Thoughts on Amber Working during the Iron Age

Amber is a fossilized plant resin found in many areas of the world, such as the Baltic Sea coastline, in Central-and South America and, more rarely, in southern Italy.

The following work aims to introduce the reader to some experiments carried out on raw Baltic amber cores, using different techniques and tools with the purpose of verifying how effective these tools can be, and any reaction of the amber. All this should confirm or refute some hypotheses regarding amber working in the Picenian context.

The amber cores used in this work come from Germany, Estonia, and Poland. The tools used have either been self-produced or made by modifying modern tools. In any case, the main guideline regarding the use of tools was to avoid any modern implement for could not be evidenced or hypothesized in a protohistoric context. There is a single exception to this guideline. That is the use of a blowtorch to heat the other tools, when needed, substituting for an open fire due to safety and practicality reasons.

Amber diffusion in the Picenian context

According to some authors (Von Eles, 1995, p.43; Naso, 2000, p.89; Von Eles, 2010, p.167; Montanaro, 2016, p.364; Naso, 2018, p.35), amber reached the Adriatic Sea from the Baltic Sea during the 9th century B.C. One of the most important points of arrival of this material was the village of Verucchio (Emilia Romagna region) (Von Eles, 1995, p.43; 2010, p.167). Here amber was either worked and/or reintroduced on the market.

The Iron Age Picenian culture which occupied the modern regions of Marche and Abruzzo, during the period from the 9th to the 3rd century BC. Negroni Catacchio (2001, pp.100-103) indicates three distinct phases of regional amber work: a rich production of geometrically shaped jewelry, a famous production of figurative ambers and lastly, poorer production localized in Abruzzo.

According to Catacchio, most of the earlier geometric jewels could be the production of local workshops that worked on amber coming from the Baltic Sea. The most ancient of these jewels dates to the 9th century BC (Catacchio, 2001, p.100). This first group includes pieces used to decorate bronze fibulae, such as single cores and discs. It also includes discoid elements that were pierced and could have been used as necklace or earrings elements. In addition to this a wide range of spheroid or cylindrical elements, pendants of various shapes, spacers, bezels, buttons and small plates of geometrical shapes inserted in artefacts of different materials also belong to this first group. There are two elements that are typical of the Picenian context: huge bronze fibulae, up to 65 cm long, decorated on the bow with amber cores that can weigh up to a kilo, and rings with a diameter of ten centimeters (See Figures 1, 2, 3 and 4).

The most ancient figurative ambers can be dated to the end of the 7th century BC (Catacchio, 2001, p.102)and belong to the so-called Orientalizing production. This group includes human figures, birds, monkeys, lions, and rams. Exclusive of the Picenian contexts are the “mascherette” (small masks), schematic representations of human faces that can be dated to the sixth century BC (Catacchio, 2001, p.102) and were probably produced locally. They were used as bezels, as confirmed by ivory winged figures whose faces, now missing, were in the past reproduced with these masks. Similar sphinxes have been found in Germany and a hypothesis of production in the Picenian area, by the hand of Greek artists, has been proposed (Catacchio, 2001, p.102).

The rich repertoire of figurative ambers composed of cores carved into feline shapes is thought to be the work of Magna Greek artists (Catacchio, 2001, pp.102-103). The magnificent amber representing Aphrodite and Anchises, now at the Metropolitan Museum, comes from Taranto and not Falconara Marittima as previously indicated (Landolfi, 2001, p.99).

Amber working started to decline in the 5th century BC, with a single discovery in the Adriatic area represented by eight ram-shaped pendants found in Abruzzo. The area declined economically and production ended in the following century, marked by a limited number of female-shaped pendants. The objects are quite rough and shows no stylistic contact with ancient production. Production can be attributed to local workers with specimens found in Numana (Marche region) and the territory of Pescara and L’Aquila (Abruzzo region).

Hypothesis of working methods and tools

The analysis of finds from the Picenian villages is not as advanced as that on cemeteries and this is preventing scholars from a wide range of data and information regarding tools and other instruments used during daily activities. Still, some research has been conducted on certain specimens.

De Marinis (2001, pp.46-47) analyzed five artefacts made from antler foundat the Bronze Age site of Moscosi di Cingoli (Marche region). The analysis produced evidence of the use of at least as many different tools some of which reflected refined technology.

Dr De Marini’s initial analyses of some worked antler simplied that they were shaped by the use of large blades such as bronze axes or knives. In regard to the cuts done to saw off single portions of these antlers, he identifies the use of a saw, moreover affirming that in some cases, the latter could have had a very limited thickness. One of the cuts has a thickness of less than 1 mm, the same as can be obtained today using a modern metalworking hacksaw.

Dr. De Marinis has identified some of the tools used to dig into the antlers and to produce quadrangular openings, using chisels with a flat, horizontal edge and gouges with a concave edge, whose clear traces he found on other artefacts.

Lastly, examining some of the holes and decorative circles on other bone specimens, De Marinis excluded the use of conical points, either made of stone and metal, instead suggesting the use of metal or hard stone hollow punches or points with crown-shaped heads either applied using a bow drill or by hand.

The use of some peculiar tools such as files, to which De Marinis alludes regardless of the lack of traces on the artifacts he analyzed, can be deduced by the typical stripes and scratches these tools left on some specimens, such as a bronze knife found in Sirolo (Fiorentini, 2018b, p.3). A whetstone, that to some extent can be associated with a file, has been found in the same Grave as the latter.

Dr. Patrizia Von Eles suggested a hypothesis on the various technologies used to shape the amber specimen found in Verucchio (Von Eles, 1995, p.44; 2010, p.169). Von Eles speculated on its production, with preliminary planning, probably using templates (Von Eles, 1995, p.44) and hot working for some objects such as fibulae or distaffs inside which decoration can be seen. Hot-working would, however, cause serious issues because it would alter the internal structure of the amber. The very same hot working technique would have been used to empty the interior of amber cores, in which decorated metal sheets would be placed before sealing the object with wax.

Regarding hot-working, other authors stated that amber “can be hot worked” (Orsini, 2010, p.29) and that "Amber processing is mechanical […]. The ability of amber to soften when hot may have been exploited […] to better shape it and to avoid loss of precious material, even if recent experiments didn’t confirm the opportunity of this technique (Caillaud, 2010, p.230)". Von Eles lastly comments on the many examples of pierced amber, although without mentioning any technique. The context having been described and the current hypothesis on amber working exposed, we will now describe the experiments conducted to verify the feasibility, advantages, and disadvantages of working amber with these tools and techniques.

Cutting amber

Two experiments have been conducted to determine how it could be possible to cut raw amber cores in order to obtain smaller semi-finished pieces that could be shaped later.

The first experiment involved a large raw core cut using a hacksaw for metals, a wire hacksaw, and a red-hot iron knife. Since any evidence of the use of vices or similar tools is missing, the amber core was held firm on the workbench with the left hand, operating the tools with the right.

The hacksaw for metals appears to be the best tool for cutting - by applying a moderate force, slowly and with care, a very precise cut is obtained. This in turn produces very few waste pieces of amber and as seen on either surface of the amber pieces, the stripes in the picture (See Figure 5). The cut was measured before detachment of the pieces, and its dimensions can be compared to the millimetric cut analyzed by De Marinis (See Figure 6).

The wire hacksaw results were less satisfactory and more problematic. The reduced dimensions of the wire, even when maneuvered with the same care as above, would not permit a cut as precise (See Figure 7). A remedy proved to be changing the position of the amber core and cutting away small portions sequentially. This may confirm the previously stated hypothesis that a template was needed for planning, e.g., a simple groove incised on the amber to use as a reference for the following cut. It is possible that rough shaping was done first, for example, to obtain a flat surface to rest the piece on before any precision cuts. Even the wire hacksaw left visible marks on the inner surfaces of the cut pieces (See Figure 8).

Cutting with a red-hot knife proved the most disappointing, to the point that it has been impossible to carry it out due to the risk of breaking the core. The iron knife was forged by Fiorentini using techniques that can be supposed in the protohistory (Fiorentini, 2013, p.4; 2018a, pp.41-43; 2020, pp.70-73). It was heated on the blowtorch to a brilliant orange and then been passed over the amber until it cooled down; then it was re-heated and the whole process was repeated.

Even if the knife sank in the amber quite easily at the beginning, this technique quickly proved disadvantageous. The first and most important point is that as the red-hot knife touched the surface of the resin, loud creaks could be heard coming from the inside of the core, which led to intuitively confirming Von Eles’s thesis (1995, p.44) that hot working of amber would alter its internal composition.

Another disadvantage was that cutting amber this way produced, on both sides of the cut, dark swellings of molten resin (See Figure 9). Those should then be removed, causing either an unnecessary waste of material and the need of a following extra work of cleaning and polishing. It is noticeable that no material was wasted during the first attempt; very little during the second. The last disadvantage was that, due to the V-section of the knife blade, cutting amber with it would produce two halves with inclined surfaces.

The second experiment was conducted on a semi-worked cylindrical amber piece from which some discs have been cut using the hacksaw for metals. Typical traces on the surfaces were left where it was worked (See Figure 10).

As a conclusion of these attempts, it can be affirmed that the hacksaw for metals was the tool giving the best results.

Piercing

Experiments on piercing were carried out firstly on the second portion of amber obtained from the first core described above. It was the core cut with the metal hacksaw on one side and the wire hacksaw on the opposite. Then piercing has been experimented on a semi-worked core and a smaller raw core. Four pendants and four duck-shaped figurines have been used for these tests too. Two instruments are used for piercing, alternating from time to time. The first was an industrial metal point for piercing wood that has been modified, reducing its diameter and mounting it on a hand drill. The second was an iron awl produced by Fiorentini that has been heated on the blowtorch to bright orange. To use the hand drill, amber pieces are held in position on the workbench, while the iron awl was held in the left hand, pushing the amber using the right hand.

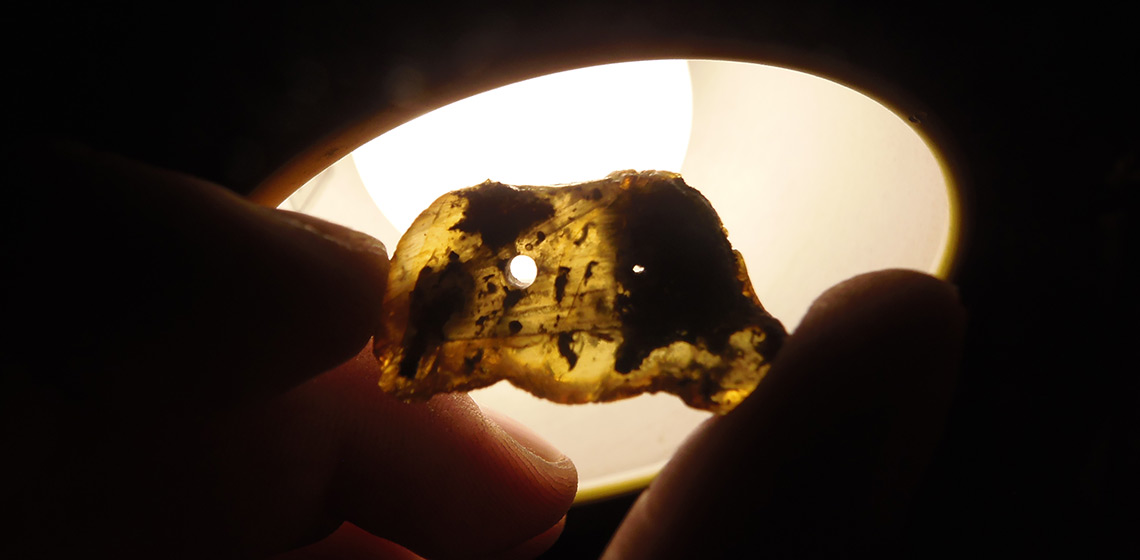

The first test was carried out on the amber “slice” obtained by the two cuts described above. This piece is also the only one pierced using both instruments, which allows closely observed similarities and differences between the two holes, e.g., different diameters, etc. (See Figures 11, 12 and 13).

Piercing by hand drill required that the amber be firmly held on the workbench, above all during the initial phases of the process when the point still had to enter the amber. Once the first tiny portion was pierced the drill could be aligned correctly. With rotation, slowly (half turn at a time), it was possible to create a hole whose borders were well defined, such as that identified in the antler artefacts studied by De Marinis.

To make the second hole, the iron awl was heated, and the amber pushed against it. As soon as the resin made contact with the red-hot metal, it punctured rather quickly and without cracks. The borders of either the entry and the exit holes obtained in this way are characterized by the presence of the lumps of dark molten amber, as described above. In a time comparison, almost ten minutes were needed to pierce the five millimeters thick amber piece by hand drill, whereas it only took one and a half minutes using the other method (See Figure 14).

The first amber core, the semi-worked one, was used to decorate the arch of a bronze fibula. It was pierced throughout its length, and while this text is being written, it is not yet finished. The red-hot iron awl was the only tool being used to pierce it. Given the amber’s length, it was pierced from the top and from the opposite end, creating two holes connecting in the middle (See Figure 15). This required preventive planning culminated in drawing a line on the external surface of the core. Piercing this piece required extra time and it is interesting to note that, now almost finished, every time the red-hot iron is applied, cracks are heard from the inside. During one of the last piercing sessions a subtle slit has been noted opening in correspondence to the entry hole, going across a portion of the core’s surface (See Figure 16).

The second amber core was pierced by mixing the two techniques; the red-hot iron awl first and then trying to finish the piercing with the hand drill. The first operation was completed without damaging the amber, except for creating molten lumps. However, while using the hand drill, the core broke just when the hole was almost finished (See Figure 17).

The four pendants can be divided into two categories: one is the replica, although smaller in size, of the “jar” pendant found in Grave 108 at Crocifisso, Matelica. The other three replicate the pendants with holes and central knot found in the same Grave (Biocco, 2008, pp.70-71,80).

All pendants were machined from solid amber using the technique described later. All of them were pierced first, using the hand drill that allowed regular holes and avoided slits.

The duck-shaped pendants were obtained from discs cut from the cylindrical semi-worked core described above, using a mixed technique that will be described below. Piercing these pendants has been carried out using the hand drill and was quite easy and fast, without damaging the amber in any way (Fiorentini, 2018b, p.3).

Some interesting conclusions can be made from these tests. The red-hot iron awl proved a useful tool to pierce the amber quickly but was also the cause of molten amber lumps, which required extra work to be removed. This is not necessary using the hand drill. Moreover, of the three pieces pierced with the iron awl, one produced the cracks and a slit, confirming Von Eles’ hypothesis that hot working could modify the inner structure of the amber.

It should still be noted that breaking happened while piercing the piece with the hand drill. On the other hand, this tool allowed for well-defined holes, also apparently submitting the material to very little mechanical stress.

It would seem possible to affirm that using red-hot tools to pierce the amber would lead to good results but also to a certain amount of extra work, that is, the need to remove the molten amber and to clean and polish the edges of the holes, plus a possibility to cause slits and inner breaks. On the other hand, the characteristics of the hand drill are quite obvious, clean, precise holes in spite of a longer operational time and the possibility of breaking the piece.

Shaping

The last experiment concerns shaping the semi-worked pieces into finished products. In this case, the objective was to replicate an archaeological specimen. This produced copies that, in case of future needs, can be used in comparison with the originals, to look for any working traces left on the latter and to evaluate the validity of these techniques.

The original specimens were found in Matelica, the four pendants in Grave 108 in Crocifisso and the four ducks decorating the polymaterial cloak clasp in Grave 1 in Villa Clara (Biocco, 2008, pp.70-71,80; Fiorentini, 2018b, p.3). The reproductions have been shaped using two techniques, that is once again testing hot working with a knife blade and working them with an iron file.

The first specimen replicated is the “jar” pendant (inventory nr. 80836, Museo Civico Archeologico in Matelica). As described above, the reconstruction began by roughly shaping an amber core with a file and then piercing with the hand drill. The shaping continued by removing the extra material using a red-hot knife blade, heating the knife and pressing it on the core’s surface tightly held in the left hand, giving it the correct shape by removing material.

The results have been quite surprising, the amber detaching in regular flakes without any visible trace or blemish on the surface. The whole process has been fast, easy, very accurate and apparently left no structural damage to the core. This method allowed the desired pendant shape to be created in a short time. At the end of the process, the file was used very lightly, just to give a more detailed finish to the pendant. (See Figure 18).

The three pendants with eyes and central knots (inventory nr. 80837, Museo Civico Archeologico in Matelica) were shaped with the same technique. The only difference was holding the knife still and moving the pieces on the red-hot blade to remove material. The process to create the central knots consisted in rotating each pendant on the red-hot blade until it dug in the furrows that define each knot, almost a turning work (See Figure 19). In this case it has been deemed unnecessary to finish the pendants with the file.

The four ducks (inventory nr. 80890, Museo Civico Archeologico in Matelica) were obtained from the discs cut from the cylindrical semi-worked core previously described. Two discs have been cut, each one mm thick and measuring 1.5cm in diameter. The surface of each disc has been engraved with the profile of two ducks.

The knife tip has then been slightly heated and used to carve the profile more deeply. Once a groove deep enough was obtained, by pushing the disc’s edges and pulling them on the opposite way, the disc broke exactly along the grove, thus obtaining two roughly shaped ducks (See Figure 20).

The next step was to pierce each duck and finish it with a file (See Figure 21). The hardest part was to produce the tiny amber nails that would have held the ducks in place on their bone support while reproducing the duck’s eyes. None of the nails are longer than five mm, and the maximum circumference is two millimeters. In order to obtain all four nails, it has been necessary to hot work a piece of solid amber, removing material (See Figure 22).

These four ducks have then been mounted on a cloack clasp (Fiorentini, 2018b); more recently two more ducks have been produced with the same technique, for didactic reasons (Fiorentini, 2021).

These experiments proved to be interesting and led to the conclusion that whenever it is necessary to work amber by removing material, a red-hot tool is by far the most practical and safe way to accomplish the task. Keeping in mind that the file can be used for finish, a red-hot knife can be used to easily carve amber, shaping it into the desired form apparently without structural damages, whereas the above described cracks and slits seem to develop when cutting and piercing.

Conclusion

As stated above these experiments had the objective of verifying the hypothesis formulated by Dr. Von Eles, especially regarding hot working.

The results obtained are interesting and various and, even if limited to a smaller number of reproductions, they can provide a starting point for further analysis.

It is clear that cold working is preferable to hot working for cutting since a hacksaw allows for clean and precise cuts. Piercing can be carried out with either technique. Cold working grants better control for the hole direction, fewer blemishes, and greater general cleanliness. It is not completely clear if hot working could cause more breaks than cold working while piercing.

Where hot working gives exceptional results is in shaping since a red-hot knife allows for quickly carving the pieces with great precision and apparently without damage to the amber. The very same results can be obtained with a file, taking longer, the work is more uncomfortable and leaves traces on the piece’s surface – traces that will have to be removed by polishing, meaning extra work.

A last note concerns the possibility of emptying entire cores, possibly in order to insert decorated metal sheets. On the face of the experiments conducted, it appears quite feasible to empty a core using a red-hot tool, maybe one of curved shape allowing to comfortably remove the material (e.g. a tiny spoon-like instrument). This could be one way to proceed; another could be to make different parallel holes with the hand drill and then remove the amber between them with a red-hot tool or a simple file.

The author is currently conducting experiments aiming to verify the feasibility of these methods and, even if it is still far from being finished and from drawing conclusions, it can be already affirmed that in order to successfully empty an amber core without breaking it needs to be solid and without internal foreign materials or breaks.

Acknowledgements

I would like to thank all EXARC editors and reviewers who worked on my article for their tireless efforts in helping me make this article understandable.

Country

- Italy

Bibliography

Biocco, E., 2008. Catalogo dei reperti n.ri 46, 48 e 71. In: M. Silvestrini and T. Sabbatini, eds. Potere e splendore – Gli antichi Piceni a Matelica, L’Erma di Bretschneider: Torino.

Caillaud, F., 2010. Conservazione e restauro dell’ambra. In: B. Orsini, ed. Le lacrime delle ninfe – Tesori d’ambra nei musei dell’Emilia-Romagna, Editrice Compositori: Bologna.

Catacchio, N. N., 2001. L’ambra. In: G. Colonna and S. Agostini, eds. Eroi e Regine – Piceni popolo d’Europa, Edizioni De Luca: Roma.

De Marinis, G., 2001. L’industria su corno di cervo e la produzione bronzistica: considerazioni tecnologiche. In: G. Colonna and S. Agostini, eds. Eroi e Regine – Piceni popolo d’Europa, Edizioni De Luca: Roma.

Fiorentini, M. A. 2013. Picenian Warrior Who Lived in the Eight Century BC: A Hypothethical Reconstruction, EXARC Journal, 2013/2, Available at: < https://exarc.net/ark:/88735/10115 > [Accessed 29 December 2021].

Fiorentini, M., 2018a. I guerrieri Piceni – Tattiche, equipaggiamento e tecnologie, Edizioni Chillemi: Roma.

Fiorentini, M., 2018b. A Seventh Century BC Picenian Cloack Clasp made of Iron, Bone, Bronze and Amber: Reconstruction of a Masterpiece. EXARC Journal Digest, 2018/2.

Fiorentini, M., 2020. Armamenti e tattiche military nella battaglia del Sentino, All’Insegna del Giglio: Sesto Fiorentino.

Fiorentini, M., 2021. Novilara dei Piceni, walk like a Picenian…, EXARC Journal, 2021/4, Available at: < https://exarc.net/ark:/88735/10612 > [Accessed 29 December 2021]

Landolfi, M., 2001. Beni di lusso, In: G. Colonna and S. Agostini, eds. Eroi e Regine – Piceni popolo d’Europa, Edizioni De Luca: Roma.

Montanaro, A.C., 2016. Le ambre figurate in area adriatica tra l’orientalizzante e l’età arcaica. Note sui centri di produzione e sulla diffusione di alcune tipologie di manufatti. In: P.L. Cellarosi, R. Chellini, F. Martini, A.C. Montanaro, L. Sarti and R.M. Capozzi, eds. The amber roads – The ancient cultural and commercial communication between the peoples, CNR Edizioni: Roma.

Naso, A., 2000. I Piceni – Storia e archeologia delle Marche in epoca preromana, Longanesi & C.: Milano.

Naso, A., 2018. Per una storia della cultura picena. In: G. Postrioti and D. Voltolini, eds. Il prestigio oltre la morte – Le necropoli picene di Contrada Cugnolo a Torre di Palme, AndreaLivi Editore: Fermo.

Negroni Catacchio N., 2001, L'ambra. In: L. Franche dell’Orto, ed. Eroi e Regine—Piceni popolo d’Europa, Galleria Nazionale d’Arte Antica, Palazzo Barberini, Rome, 12 April–1 July 2001. [Exhibition catalogue] Rome: Edizioni De Luca.

Orsini, B., 2010. Ambra: le origini, il mito e il commercio nell’antichità. In: B. Orsini, ed. Le lacrime delle ninfe – Tesori d’ambra nei musei dell’Emilia-Romagna, Editrice Compositori: Bologna.

Weidig, J., 2020. Cofanetto in avorio e ambra, mito greco a Belmonte Piceno. In: Vv. Aa., ed. Belmonte Piceno prezioso scrigno della Marca Fermana, Volume I, Albero Niro Editore, Roma.

Weidig, J., 2017. Ambra e avorio. In: J. Weidig, ed. Il ritorno dei tesori piceni a Belmonte. La riscoperta a un secolo dalla scoperta, ASTRA Edizioni, Belmonte Piceno.

Von Eles, P., 1995. L’ambra: il mito, la provenienza, le tecniche. In: P. Von Eles, Verucchio, Museo Civico Archeologico – Guida alla visita, Provincia di Rimini. pp. 43-45.

Von Eles, P., 2010. Il ruolo di Verucchio nella circolazione e nella lavorazione dell’ambra durante la prima Età del Ferro in Italia. In: B. Orsini, ed. Le lacrime delle ninfe – Tesori d’ambra nei musei dell’Emilia-Romagna, Editrice Compositori: Bologna.