The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

An Experimental Exploration of the Earliest Soapmaking

Soap is a substance now taken for granted, but there is uncertainty, myth and misinformation about its development, and little scholarly attention has been paid to the likely circumstances surrounding its discovery. As part of a MSc in Experimental Archaeology, a project collated the earliest mentions of proto-soaps, reassessed previous experimental conclusions, and developed testable scenarios to explore how soap was first discovered, suggesting that the degreasing of fatty cloths after straining perfumed fats and oils may provide the conditions under which soap was first reliably and repeatedly observed. This paper offers a condensed version of this work.

What exactly is soap?

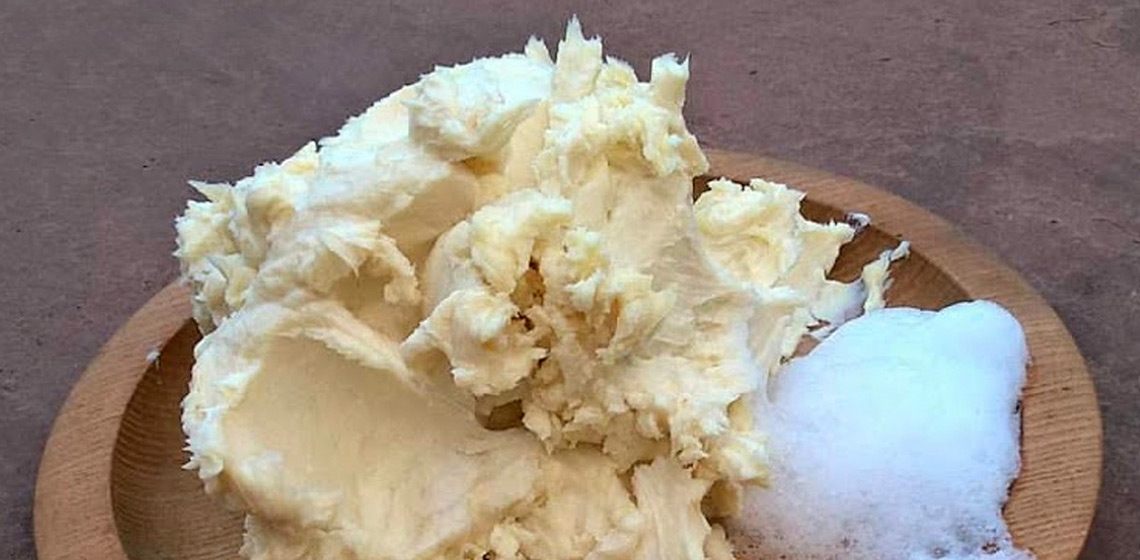

Soap is formed when fats combine with alkali in the right proportions and under the correct conditions. The process is described as saponification and historically, the fats may be animal fat such as tallow or vegetable fat such as olive oil, the alkali may come from wood ash lye, or a mineral alkali such as natron and may be strengthened with lime. If all goes well, the result is soap and glycerine, though an imperfect reaction may leave excess fats or lye in the mixture. Soap formation requires more than just alkali and fat in the right proportion, it also requires time, heat, and usually, agitation. As an analogy, it is like suggesting that a cake is made by combining flour, butter, eggs, and sugar - only when the proportions and conditions are right will a cake be the result (See Figure 2).

Myth and Misinformation

A glance at the internet shows several frequently repeated but erroneous 'facts' about early soapmaking, and these also appear in otherwise well-intentioned publications. From fanciful ideas about ashes blowing into pots of fatty soup, or even fats and ashes from sacrificial alters mingling with rainwater, to a pseudo-Galenical quote that describes the method of making soap, but which was not actually written until the sixteenth century (Everett 2012), to reports that a 'soapmaking factory' which was actually a fullonica (effectively, a Roman laundry) was uncovered at Pompeii (Gusman 1900), or that Phoenicians brought soapmaking to Western Europe (Wilson 1959). All of these can be demonstrated to be inaccurate.

It has been more plausibly theorised that the use of alkali to degrease fleece may be where soap is first observed, (Cassidy 2020). The properties of alkali to clean textiles were undoubtedly known (Levery 1958; Wassermann 2013) however only if a reasonable quantity of fat is fully saponified by the lye would soap form in visible quantities, and wool washing does not produce these conditions.

Little work has been published on very early soapmaking. Hedge (1997) is one of the few researchers to compare the commonly reported beliefs to an experimental approach. His work is amongst the most detailed to date, yet he too repeats some common misconceptions and does not suggest any scenarios for the discovery of true soap. He does highlight that whilst the key ingredients may be combined in several ways, it is time that is critical for the formation of soap (1997, p.3). An often-overlooked condition is that not only does a substance need to form, but an observer needs to notice and be able to investigate further. It is possible that traces of soap formed on many occasions, but only when people recognised its effects and replicated it did it become widely known.

Using documentation to narrow down the possibilities

Sumerian, Babylonian, and Egyptian texts reference "proto-soaps" indicating that the properties of fats and alkali were understood over four millennia ago, although tracing this is complicated by some words being used to interchangeably to describe alkalis, soap-like substances, and cleansing. It is another 2000 years before both Greek (Galen, Method of Medicine, VIII. line 569k) and Roman (Pliny, Natural History, XXVIII.191; Martial, Epigrams, VIII.20; XIV.27 & 27) authors mention soap. This leaves a large tempero-spatial gap between substances that include the right ingredients but are not true soap, and soap being a known if not widespread commodity (See Figure 3).

There is one scenario which contains the right ingredients and conditions present for true soap to form on repeated occasions, and in a setting where its cleansing properties would be observed by people able to recognise the implications and build an understanding that at some point was used to further refine the product. The well documented perfume industries of the ancient world (Forbes 1964; Balasubramanian 2015) were straining relatively small quantities of aromatic oils and fats through woven cloth. Normal rendering of fats does not typically require straining, as the solids float above the rendering liquid and can be skimmed or lifted off, but perfume making starts with purified fat or oil in which aromatics are steeped before filtering through cloth. These cloths are a valuable resource and would need specialist laundering to degrease them for re-use. Evidence indicates that laundering could be a formal profession, often carried out by male workers as well as being a domestic undertaking, and that strong alkali was being used to degrease textiles, often in domestic sized pots or tubs (Waerzeggers, 2006; Wasserman 2013)

Boiling fatty cloths in strong lye in conditions where regular stirring and observation of their progress occurs is exactly the setting in which any formation of soap may be both noticed and remarked upon. It is also likely to occur on repeated occasions.

Testing this experimentally

Experiments were conducted to see whether the laundering of greasy straining cloths in lye could produce observable and repeatable soap foam. Potash, a mixture of water-soluble potassium compounds, including potassium carbonate, potassium hydroxide and potassium chloride, is regularly found in mentions of proto soaps. It can be made by dissolving wood ashes in water, straining the mixture, then used fresh or by evaporating off the liquid to leave potashes. Typical wood ash from hardwood plants will contain around up to 5% potash (Dampier 2020).

A quantity of lye was made by percolating rainwater through a barrel of ashes, drawing, in the absence of earlier examples, on references from the twelfth century Mappae Clavicula which describe the filtering of ashes through sticks and straw. The lye produced had a dark brown colour from tannins in the sticks and wood shavings used as a filter, and this does reflect in the colour of the liquid and foam in the images here. Despite having made lye many times before, an excess head of pressure meant some spillage on tapping the barrel, reinforcing the advisability of gloves and goggles. Universal indicator papers showed the lye was strongly alkali at this stage.

The lye was tested for strength using a traditional method of floating an egg in it. In plain water a fresh egg will sink, in lye of soapmaking strength it will float with a portion above the liquid. A 'feel and taste' test was also carried out, the lye felt soapy on the fingers, indicating that it was actively degreasing, and had 'bite' on the tip of the tongue indicating alkalinity. This batch whilst alkaline, was not yet at soapmaking strength as the egg still sank, and this was confirmed by using a homebrew hydrometer to compare the specific gravity of this lye, a control lye of known soapmaking strength and plain water (See Figure 4).

Experiment one

Degreasing fatty cloths using lye

This aimed to clarify what is needed to degrease greasy fabric and to observe whether any soap formation may be observed. Three tests were set up using uniform samples of linen cloth through which beef tallow had been strained:

- Commercial Potassium Hydroxide. A lye calculator (MMSLye) confirmed precisely how much alkali was necessary to fully saponify the amount of fat. This lye was used in extreme dilution, to see whether the right amount of alkali was enough to allow saponification to happen (See Figure 5a).

- Wood ash lye straight from the barrel. While not at traditional soapmaking strength, would it be strong enough to efficiently degrease textiles? (See Figure 5b)

- Wood ash lye concentrated by boiling to 'strong enough to float an egg' ('Strong Lye'). (See Figure 5c)

Initially 500ml of liquid was used in each pan, but after 45 minutes simmering an additional 500ml was added to each to maintain a good level of liquid (See Figures 5 and 6).

Results

- Enough alkali is theoretically present to fully saponify the fat and clean the fabric with 0.04g fat remaining behind, but in such dilution the reaction is invisible to an observer beyond the creation of a trace of foam. Concentration is therefore important to observe soap formation.

- The fabric was efficiently degreased with only 0.02g fat remaining in fabric after rinsing. Light foam when stirring might be observed but is not at remarkable levels. The lye could be topped up and reused after skimming off solidified fat the next day.

- The creation of foam at every stage is sufficient to be noticed, and the strong lye probably represents enough of an investment of effort to warrant reusing it. The fabric, slightly stained by the lye, ended up fractionally lighter in weight than at the start. When washing up, an impressive head of good-quality soap foam formed which could not have failed to be commented on in antiquity.

Experiment two

A second experiment of two samples using larger amounts (50g) of fat in strong lye (See Figure 7), and lye causticized by the addition of lime water confirm that whilst full saponification did not quickly occur, enough of the visible changes are present for repeated observation of the processes in action.

Other investigations were made using lye concentrated to the point where crystallisation occurred but were inconclusive as to their practicality.

Conclusion

In this scenario, using strong wood ash lye (optionally with a little mineral-based alkali such as slaked lime) to degrease fatty cloths, saponification will occur and in a form that would be observable and repeatable. This is consistent with resources, activities and references identified within the Mesopotamian area over four thousand years ago, and plausible across the wider Ancient World, supporting the ideas that at a time when the cleansing properties of alkali were known, an understanding of the factors necessary to properly saponify fats and alkali was developing and could be observed across any culture that needed to degrease oily cloths.

Several observations were standard to all methods where the conditions allowed saponification to occur:

- Foaming happens immediately the lye and fats are combined. This may represent small amounts of potassium hydroxide combining easily with fat, the other alkali compounds taking longer to work.

- Even when fat globules remain on the surface, degreasing textiles is efficient and reliable in all tested alkali solutions.

- Strength is important. If the lye is too dilute, even containing enough alkali needed to convert a given amount of fat, no visible reaction will occur although cloth is largely degreased.

- Heat is important. The best samples were warmed either over a long period or were reheated several times.

- Agitation is important. Passive mixtures of fat and lye only saponify at the point that they touch, and little change is observable. The stirring of cloths or deliberate mixing brings fat and lye into more complete contact giving better saponification.

- Time is critical. Although initial foam may be observed, any visual change in the nature of the fat globules into something that may be remarked upon takes at least an hour and more often overnight.

For any observation to be significant, it must also be noted by someone who considers and elaborates on their discovery. It seems likely that the empirical principles of soapmaking were known for centuries before someone experimented with concentrating the product and separating it from the free lye.

That this occurred by the first century AD is indicated by Roman references, but we do not know exactly when the shift from soap being an imperfect mixture of ingredients used as a cleansing paste, then an observed by-product of degreasing, to finally becoming a commodity occurs. The linguistic difficulties of having one-word cover several variants of potash, alkali and soap contributes to the challenges in tracing its history. If development happened in regions without a written history, this becomes very difficult to trace.

Further work

Further work using replica pots and heating sources is planned to compare observations using modern pans to historical conditions. There are several alkali sources available to the Mesopotamian world (Levey 1958) and more complex lye made using more than one alkali source may be even more efficient. Using cloths from more specific perfume recipes that use named fats or oils may also give different results.

An EXARC Podcast 'The Meaning of Cleaning' published 2/2/2024 features a discussion between Sally Pointer, Dr Sara Robb, and Jess Shaw exploring this topic and soapmaking in more detail.

Bibliography

Balasubramanian, N., 2015 Scented Oils and Perfumes. Chemical Technology in Antiquity, pp. 219-244.

Cassidy, C., 2020. Who Discovered Soap? What to Know About the Origins of the Life-Saving Substance. Time. [online] Available at: https://time.com/5831828/soap-origins/.[Accessed 13 August 2024]

Dampier, J., 2020. [SU1] Using Wood Ash in the Home Garden. Wisconsin Horticulture. [online] Available at: https://hort.extension.wisc.edu/articles/using-wood-ash-in-the-home-garden/. [Accessed 13 August 2024]

Everett, N., 2012. The alphabet of Galen: pharmacy from antiquity to the Middle Ages: a critical edition of the Latin text with English translation and commentary. Toronto: University of Toronto Press.

Forbes. R.J., 1964. Studies in Ancient Technology. Volume IV. Leiden: E.J. Brill.

Galen. Method of Medicine, Volume II: Books 5-9. Johnston, I. and Horsley, G.H.R., eds. 2011. Translated by I. Johnston and G.H.R. Horsley. Loeb Classical Library 517. Cambridge, MA: Harvard University Press.

Gusman, P., 1900. Pompei, the City, Its Life & Art. W. Heinemann.

Hedge, R.W., 1997. The Discovery and Prehistory of Soap: A historical perspective and banausic interpretation, Monograph Series No.2, Butser: Butser Ancient Farm.

Levey, M.,1958. Gypsum, salt, and soda in ancient Mesopotamian chemical technology. Isis, 49(3), pp.336-342.

Martial. Epigrams, Volume 2: Books VIII & VIV. Shackleton-Bailey, D.R., ed. 1993. Translated by D.R. Shackleton-Bailey. Loeb Classical Library. Cambridge, MA: Harvard University Press.

MMSLye: Majestic Mountain Sage, Inc., n.d. Lye Calculator - TheSage.com. [online] Available at: https://www.the-sage.com/lyecalc/. [Accessed 13 August 2024]

Pliny. Natural History, Volume VIII: Books 28-32. Translated by W. H. S. Jones. Loeb Classical Library 418. Cambridge, MA: Harvard University Press, 1963

The Electronic Text Corpus of Sumerian Literature, n.d. Faculty of Oriental Studies, University of Oxford. Available at: https://etcsl.orinst.ox.ac.uk/cgi-bin/etcsl.cgi?text=t.2.1.7# [Accessed 14 December 2021].

Waerzeggers, C., 2006, Neo-Babylonian laundry. Revue d'assyriologie et d'archéologie orientale, 100 (1), pp.83-96.

Wasserman, N. 2013. Treating Garments in the Old Babylonian Period: "At the Cleaners", A Comparative View Iraq, 75, pp.255-277.

Wilson, R.L., 1959. Soap through the Ages. London: Unilever Educational Publications.