The content is published under Creative Commons Attribution 4.0 International license.

Reviewed Article:

Technical Elements for Etruscan-Padan Kilns Firing and Female Labour Connected to These Tools

This article presents work connected to the GestiRitrovati project, the association that performs archaeological experiments at the Forcello Archaeological Park (Mn). The aim is to recover archaic customs of Etruscan-Padan pottery production...

The aim is to recover archaic customs of Etruscan-Padan pottery production1 . In particular this essay tries to solve the problems found during experiments to recreate PadanBucchero2 . The research method used to solve the problems is experimental archaeology.

Problem

Since 2006, at the Forcello Archaeological Park (Mn), GestiRitrovati has performed several experiments to recreate PadanBucchero in Etruscan-Padan kilns3 . During firing tests in highly reducing atmosphere4 , performed in May 2007 (Deriu 2009, 40-42), there was a problem with the colour of the bowls, which were a reddish colour in places, instead of the peculiar black colouring typical of Bucchero. Reddish tones appeared near the stacked bowls contact points, where there was not a free circulation of carbon monoxide, which usually gives the black colour. Moreover, a characteristic red circle on the bottom of the bowls feet, called a ‘stacking disk’ appeared (Cuomo di Caprio 2007, 528-529) (See Figure 1), as artefacts that were directly in contact with the slotted platform experienced excessively high temperatures. There is no trace of this irregular colouring in the original Bucchero bowls5 .

Archaeological experiments aimed to reproduce, performed at Forcello Archaeological Park, show that it is necessary that warmth spreads in a uniform way inside the firing chamber to avoid irregular colouring. Moreover, mainly for Bucchero, uniform circulation of reducing gas must take place so that the artefacts can develop the typical black colouring. Both requirements find a solution in properly stacking the bowls inside the firing chamber.

Archaeological sources

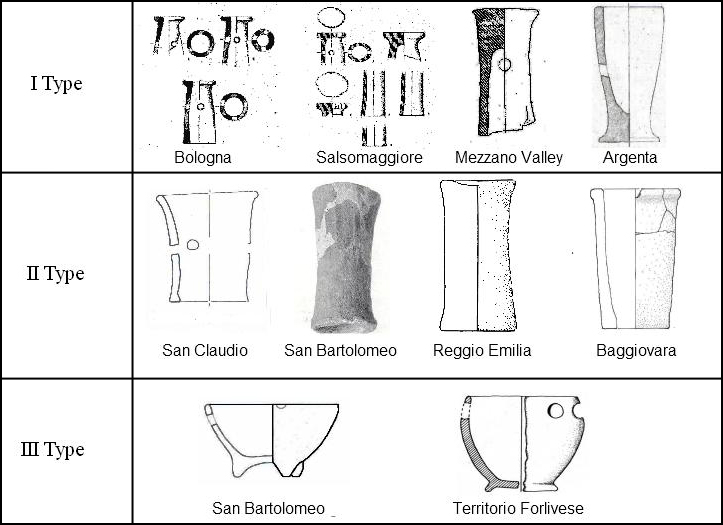

To avoid excessive local temperatures over the slotted platform, where flames, smoke, ashes and hot gases rise, we believe that supports were used to separate artefacts from the platform (this supposition in based on archaeological records). Either in Greece6 or in the West7 , from the Archaic Age to later periods, we record unturned wedge and stirrup shaped supports and big, turned ring shaped supports that were insert between the slotted platform and the artefacts to increase the stability of stacks or to separate the artefacts from the platform. Ethnographic analogy suggests two other possible solutions: first one is to put pottery fragments on the slotted platform in order to avoid the direct contact between the artefacts and the fire; second is to place tiles or bricks between the platform and the bowls. Both these solutions were used until recently by the potter CosimoVestita from Grottaglie (Cuomo di Caprio1982, 165-180). In Etruscan-Padan plain, the archaeological analysis of the technical elements called ‘supports’ contributed to a primary and temporary classification based on empirical analysis (See Table 1).

Table 1. Supports

The first type, including technical elements found in the San Vitale necropolis in Bologna (Taglioni 1997, 207-224), in Argenta (BermondMontanari 1993,248-252), in Mezzano Valley (Taglioni 1997,216) and in Salsomaggiore (Taglioni 1997, 215-216), has a cylindrical body with breathing holes and a plain disc on one side and it is datable from tenth to eighth century BC. The second type, formed by technical elements found in Verucchio (Gentili 1987, 257-258), in San Claudio (Malnati, Losi 1990, 87-125), Baggiovara-Martiniana route (Zamboni 2003-2004, 114), San Bartolomeo-Case Bigi (Patroncini1970, 88-89) and some elements which are part of the Municipal Museum of Reggio Emilia (Damiani, Maggiani, Pellegrini, Saltini, Serges 1992, 344), has an hollow cylindrical body without a proper plain disc, but with lips slightly expanded and breathing holes. This type is datable from the late ninth century until the sixth century BC and is comparable with the supports found in the Palaeoveneto kiln in Crosare di Bovolone (Salzani 2002, 178), used to cook big pots upside down. The third type, including technical elements found near Forlì (Von ElesMasi1982, 262-263), in San Bartolomeo-Case Bigi (Damiani, et al. 1990, 141-145) and in Baggiovara-Martiniana route (Zamboni 2003-2004, 114), has a vase shaped body with breathing holes and it is datable from the sixth century to the first half of the fifth century BC. There are several interpretations made by scholars about this technical element’s function and, although I believe that only an experimental approach could prove their aim, it seems that elements included in the first and the second group were used to cook big pots upside down. Then it is possible that supports’ aim varied according to the their use, inside the firing chamber with slotted platform could be used to support big vases; when pots were in direct contact with fuel, supports were used to keep artefacts separated from coals.

In the case of Bucchero, we saw that uniform circulation of reducing gases must take place in order to obtain typical black coloured potteries. To satisfy this requirement, kiln firing supports were used during the stacking to avoid irregular colourings in the points of touch between the artefacts and to stabilize the entire ceramic charge. These technical elements made by potter's wheel had different shapes and were equipped with breathing holes (See Figure 2); they are recorded either in Greece (Papadopoulos 1992, 203-221; Kaloyeropoulou1970, 429-434; Monaco 2000, 91-93) or in the West (Cracolici2003, 19-24). In Padan Etruria, Spina is the site where, from a quantitative point of view, important find of large quantity of kiln firing supports dating back to Hellenistic Age have been recorded.

Kiln firing supports have such a remarkable variety in shape and size that PatitucciUggeri (1988, 624-632) was able to create a classification system, Groups I to IX are composed of stacking rings; Group X is composed of bell shaped kiln firing supports, Group XI is composed of sub-cylindrical supports and Group XII is made up of big, large and broad stacking rings (See Figures 3 and 4). In this classification supports from the Archaic Age, found in Marzabotto (Saronio1965, 385-416) and Adria (Bonomi,et al.1999, 212-235) are included. It is important to underline that in Spina two kiln firing supports have been found tied to the bottom of a grey ware bowl (PatitucciUggeri1984, 168), because this ceramic class is probably a derivation of Bucchero (Ciampoltrini 1990, 278; Malnati 1993, 47; Casini 2007, 242; Deriu 2009, 39-44); this confirms the use of kiln firing supports also for Bucchero. Moreover, supports were found with the grave goods of two women (graves 113 and 366) in the Spina necropolis (in Trebbia Valley). Their presence could indicate the work of the deceased during their lives. For this reason, I personally experienced the production of kiln firing supports using a potter's wheel.

The experiment

The archaeological research I have described so far aims to find the most suitable supports8 and kiln firing supports to stack bowls according to the archaeological finds at Forcello and to solve problems that GestiRitrovati found during former experiments to reproduce Padan Bucchero. The hypothesis to be verified in the archaeological experiment is based also on the fact that Etrurian-Padan pottery production from the middle of the VI to the beginning of the IV century BC (during Forcello settlement) reached the specialization level (Casini S., et al. 1986, pp. 246-265). This assumption makes me believe that work was functionally managed in order to get a good pottery product, for which pottery manufacturing last step, firing, turns out to be fundamental. In this perspective, tools main purpose should be to guarantee safety and functionality. In particular, we assume that any morphological features regarding kiln firing supports should aim to pile up as many artifacts as possible inside the kiln firing chamber and, at the same time, to guarantee a successful firing and consequently a good product.

First of all, artifacts stacks balance inside the firing chamber must be ensured; this should be obtained by using supports shaped in order to fit the pots to be piled, and, as consequence, these tools feature technical elements to reach this purpose. In particular, kiln firing supports upper lip should perfectly fit pot foot and, at the same time, lower lip should be shaped and sized to give pot a stable base on the tank bottom. Moreover, kiln firing supports must bear loads caused by piled pots which may vary depending on the pots weight; in order to fulfil this requirement, in addition to previous morphological features, technical elements sides should have adequate thickness to support the whole pottery load. Economical requirement to pile as many pots as possible should be granted by kiln firing supports height, which at the same time, should also be the minimum needed to ensure that pots surfaces remain separated one from the others. Based on these considerations chose two different types of kiln firing supports to verify during the experiment: the first one is a stacking ring and it is included in PatitucciUggeri Group VIII; the second one is a bell shaped support, and it is included in PatitucciUggeri Group X. In the experiment I wanted to verify several hypotheses:

- The actual functionality of using kiln firing supports to produce Padan Bucchero;

- The fact that kiln firing supports were produced on the basis of the shape of pots to stack; in particular, the technical element upper lip should exactly fit the inner part of the bowl foot and, in the same way, the lower lip should have the right shape and diameter to guarantee a steady placement on the bottom of the bowl;

- The importance of the kiln firing support shape related to its functionality. Shape is, then, a variable to test;

- The role of women’s labour in the ceramic production workshop.

The experiment, was conducted with an electric kiln in order to compare modern production data with data from the, supposedly, traditional Etruscan method to be verified by conducting several experiments repeatedly (Coles 1981, 10), following Coles’ protocol on reducing and oxidizing atmosphere in firing experiments (Coles 1981, 147). Moreover use of an electric kiln reduces factors that may vary in the experiment such as humidity and temperature and gives representative data sample regarding hypothesis to be tested. Potter Giuseppe Laschera made twelve bowls based on the pot found in Forcello (De Marinis and Rapi 2007, 111). These were divided in two different stacks: the first one was piled up using six bell shaped kiln firing supports; and the second one using six stacking rings (See Figure 5). I made both these elements with an electric potter's wheel on the basis of Etrurian-Padan archaeological records. The entire ceramic load was stacked inside two sheet metal boxes9 with reducing elements such as bones, rinds and sawdust to obtain a very strong reducing atmosphere. Firing started the 27th of July 2009 and reached a temperature of 950°C10 . The electric kiln was opened the 30th of July 2009.

Results

The bowls were a shiny black, and in some cases they were black with silver flecks11 ; this means that pottery similar to Bucchero and silver Bucchero, Bucchero with metallic flecks, was produced (See Figure 6). Afterward I proved their water resistance by an empirical verification: once cooked, I put the bowls in the running water and I noticed that water fast slipped away; impermeability was reached by rubbing the bowls to leather hard by using a stone that, transferring mineral salts on the artefacts surface, obstructed their pores. This showed that the temperature reached inside the smaller box was not less than 700°C / 750°C12 . Almost all the bowls have a dull dark grey circle or a “stacking disk” on the bottom of the tub (See Figure 7), in correspondence to the kiln firing support foothold; all the bowls’ feet have a uniform black colouring.

Outcome

According to the results, the hypothesis that kiln firing supports were used to produce Padan Bucchero is correct. The technical elements used allowed reducing gases to reach all of the ceramic body or, alternatively, dark grey circles or ‘stacking disks’ would have been red. So it might be possible that, optimizing the kiln firing supports by reducing and slightly bending their lower lips, the presence of the dull dark grey circle or stacking disk can be avoided. The actual functionality of kiln firing supports confirms the hypothesis that these technical elements were made on the basis of the pot’s shape, so this could be a possible practice used in the archaic ceramic workshop. This hypothesis seems to agree with archaeological data in Forcello about findings of Padan Bucchero bowls with feet of different kinds (Casini and Frontini 1989, 152). Kiln firing supports shape does not seem to influence the final result, since no differences in results was associated with this variable among the experimental artefacts of the two stacks. So it might be possible that the choice of the kiln firing supports shape (for similar sizes) was made according to the potter skill and handiness. If the hypothesis that kiln firing supports were made on the basis of the pots shape is correct, the logic consequence is that technical elements and artefacts were made using a potter's wheel by the same person.

My direct experience confirmed this last hypothesis. During my training I developed an adequate technique that allowed me to make supports using a potter’s wheel, while to realize more ornate artefacts (for example bowls for my experiment) much more time and experience are needed. This medium technical competence gave me the chance to personally experience how difficult it is to make adequate tools for specific pottery shapes. So, in my opinion, it is more likely that the potter made the supports by himself. In addition, because of the lack of archaeological data, it is hard to believe that a woman could hold that role. This hypothesis is also supported by the ethnographic analogy; indeed, based on the Murdock and Provost study about sexual labour division based on 185 current ethnographic cases, pottery making is included in activities regarding both sexes. When more sophisticated approaches and tools were introduced, activities related to these new facilities were mainly performed by men. So I think that women could probably have helped the fornaciaio in stacking pots using kiln firing supports. This charge could be commissioned to a woman for her thinner body, because this feature allows stacking easily the pots inside a firing chamber of a kiln with stable dome (such as the kilns reconstructed in Forcello Archaeological Park). Regarding other activities performed by women in archaic ceramic workshops, it is possible to mention two sources. The first from Padan Etruria is the discovery of a punch with circles, a tool used to decorate pots, found in a woman's grave goods (I/1975) in Casalecchio di Reno (See Figure 8). The second one is the Attic Kalpis by the Leningrad Painter, found in a woman’s grave in Ruvo di Puglia; the red-figure scene represents a craftswoman painting a crater (See Figure 9).

Further experiment on technical elements for Etruscan-Padan kilns firing

The experiment on Padan Bucchero was made with an electric kiln to get the chance to compare modern production data to the supposed traditional Etruscan method that will be tested in a further firing using the kilns built in Forcello Archaeological Park (Mn). Regarding a reducing firing process, it is important to test kiln firing supports for the grey ceramic class as well. Moreover, some ethnographic examples of kilns, similar to the reconstructed ones (Cuomo di Caprio 2007, 533), indicate that kiln firing supports were also used in oxidizing firings, so it is necessary to test the use of technical elements in other Etruscan-Padan ceramic classes. Ultimately, technical elements, called supports, will be experimented with in order to understand their use and their functionality.

- 1The ceramic production called “Etruscan-Padan” pottery (De Marinis 1982, 498), according to its extension, it can be dated between the second half of 6th century and the first half of 4th century BC. Itsdistributionisattestednear Bologna, in Reggio province, in Spina, in Romagna and in Mantova province (Forcello, Castellazzo della Garolda). The Etruscan-Padan pottery, an evolved and standardized production, is subdivided in three ceramic classes: Bucchero, gross ceramic and purified uncolored ceramic. Moreover, between the 5th and the 3rd century BC , when PadanBucchero gradually disappeared, this ceramic class was replaced with a typical grey-coloured ware.

- 2The term Bucchero indicates a ceramic class from Etruscan tombs of Tuscany and Lazio. Its distinctive aspect is jet black coloured surfaces and black ceramic body (Cuomo di Caprio2007, 437-440). The term PadanBucchero was created to distinguish Etruscan production of the Padan plain (Italy) from Bucchero produced in South Etruria (Casini 2005, 264).

- 3The kiln was built by Roberto Deriu from GestiRitrovati. The model is based on archaeological findings in Marzabotto.

- 4During a highly reducing firing process”combustion in lack of oxygen causes dry distillation of the fuel through the formation of carbonic particles and carbon monoxide, a strongly reducing agent”. In this firing process iron oxides (red coloured) turn into ferrous ferric oxides (black coloured) (Cuomo di Caprio2007, 438).

- 5This is a quite common flaw in the Greek and Etrurian coeval pottery productions, in particular in the black painted pottery, where a wider demand probably allowed a second choice products trade. In Padan Etruria this flaw is not very common, as it appeared mainly in the black painted pottery which is a later and localized production of the Padan plain.

- 6Kiln firing support is the small, semielliptical leaf-, drop-, or pear-shaped clay plaques were found: in Corinth (Kaloyeropoulou 1970, 433); in Epitalion (Kaloyeropoulou1970, 431) and in Athens (Papadopoulos 1992, 211). Big ring shaped kiln firing supports were found: in Corinth (Pease 1937, 299); in Corfù (Preka, Alexandri 1992, 41-51); in Cnosso (Hayes 1971, 269); in Camiro (Jacopi 1931-1932, 65); in the Athenian Agorà (Sparkes andTalcott 1970, 368) and in Olinth (Robinson 1929-1950, 391-392).

- 7Wedge and stirrup shaped supports were found: in Taranto (Dell'Aglio1996, 27-34); in Metaponto (Cracolici2003, 97-98).

- 8In case of small or medium size pots, I believe that some ceramic fragments were used. This practice was already experienced by GestiRitrovati.

- 9The use of a sheet metal box is necessary to get a firing in a strong reducing atmosphere. This practice was already tested by Potter CesareCalandrini (Caruso 1989, 39-40).

- 10Practical demonstrations have shown how it is possible to obtain Bucchero from common pottery clay firing at medium to low temperatures (about 800°C) (Cuomo di Caprio 2007, 438). The choice of using two boxes instead of one was made to isolate the ceramic load to reach the ideal temperature to obtain Padan-Bucchero.

- 11Subsequently, with the help of Potter Marcello Mannuzza, I found out that the presence of silver flecks on the bowls was due to the type of sawdust I used, and that was obtained from pitchy wood.

- 12Firing was made in a kiln with other artefacts so I couldn't use thermocouples and I do not have further information about the temperature reached during the experiment.

Keywords

Country

- Italy

Bibliography

BERMOND Montanari G.1993: Il territorio di Spina. L'insediamento protostorico del podere Boccagrande di Argenta, in Spina, pp. 248-252.

BONOMI S., CAMERIN N., TAMASSIAK.2002: Adria, via San Francesco, scavo 1994: materiali dagli strati arcaici, in Padusa XXXVIII, pp. 201-213.

CARUSO N. 1989: Ceramica viva. Manuale pratico delle tecniche di lavorazione antiche e moderne dell'oriente e dell'occidente, Milano.

CASINI S., FRONTINI P., GATTI E. 1986: La ceramica fine, in Atti del Convegno Gli Etruschi a nord del Po, Mantova (1986), pp. 246-265.

CASINI S., FRONTINI P. 1989: Prime osservazioni sulla ceramica grigia del Forcello e del Castellazzo della Garolda, in Atti del Convegno Gli Etruschi a nord del Po, Mantova (1986), pp. 152-158.

CASINI S. 2007: La ceramica di produzione locale: impasto, bucchero, etrusco-padana, in De Marinis R., Rapi, L'abitato etrusco del Forcello di Bagnolo San Vito (Mantova) – Le fasi di età arcaica, Mantova, pp. 229-245.

CIAMPOLTRINI G.1990: Pozzi, via del Poggione (Seravezza), in Versilia, pp. 129-133.

COLES J.1981: Archeologia sperimentale, Milano.

CRACOLICI V.2003: I sostegni di fornace dal kerameikos di Metaponto, Bari (BACT, Beni Archeologici, Conoscenza e Tecnologie, 3).

CUOMO DI CAPRIO N. 1982: Ceramica rustica tradizionale in Puglia, Galatina -Lecce.

CUOMO DI CAPRIO N. 2007: La ceramica in archeologia 2. Antiche tecniche di lavorazione e moderni metodi di indagine, Roma.

DAMIANI I., PELLEGRINI E., Saltini A.1990: San Bartolomeo-Case Bigi. Insediamento con impianti produttivi, in Vestigia Crustunei, pp. 141-145.

DAMIANI I., MAGGIANI A., PELLEGRINI E., SALTINI A, SERGES A. 1992: L'età del ferro Reggiano. I materiali delle collezioni dei musei civici di Reggio Emilia, Reggio Emilia.

DE MARINIS R.C.1982: Bagnolo San Vito (Mn), in Studi Etruschi L, pp. 495-502.

DE MARINIS R.C., Rapi M. 2007: L'abitato etrusco del Forcello di Bagnolo San Vito (Mantova) – Le fasi di età arcaica, Mantova.

DELL'AGLIO A. 1996: Taranto, in Arte e artigianato, pp. 27-34.

DERIU R.2009: From Bucchero to the grey ware in the Po valley: experimenting with the importance of firing, in EuroREA, 6, pp. 39-44.

GENTILI G.V.1987: Verucchio. L'abitato villanoviano ed il successivo tra fine VI-V secolo a.C., in Bermond Montanari G., La Formazione della città in Emilia Romagna. Prime esperienze urbane attraverso le nuove scoperte archeologiche II, Bologna, pp. 257-258.

HAYESJ.W.1971: FourEarly Roman Groups from Knossos, in BSA LXVI, pp. 249-275.

JACOPI G.1931-1932: Esplorazione archeologica di Camiro-I. Scavi nelle necropoli camiresi, 1929-1930, in CIRhodos IV.

KALOYEROPOULOU A.1970: From the Techniques of Pottery, in AAA (AthensAnnals of Archaeology) 3, pp. 429-434.

MALNATI L., Losi A.1990: San Claudio. Abitato con impianti produttivi, in Vestigia Crustunei, pp. 87-125.

MALNATI L. 1993: Il bucchero in Emilia. Elementi per una catalogazione preliminare, in Bonghi Jovino M., Produzione artigianale ed esportazione nel mondo antico. Il bucchero etrusco, Atti del convegno internazionale (Milano, 10-11 maggio), Milano, pp. 43-71.

MONACO M.C.2000: Ergasteria. Impianti artigianali ceramici ad Atene ed in Attica dal protogeometrico alle soglie dell'ellenismo, Roma.

MURDOCK G.P., PROVOST C. 1973: Factors in the division of labour by sex: a crosscultural analysis, in Ethnology XII/2, pp. 202-225.

PAPADOPOULOS J.K.1992: Λασανα, Tuyers, and Kiln Firing Supports, in Hesperia v. 61, n° 2, pp. 203-221.

PATITUCCI UGGERI S.1984: Classificazione preliminare della ceramica grigia di Spina, in Cultura figurativa e materiali tra Emilia e Marche. Studi in onore di M. Zuffa, Rimini, pp. 139-169.

PATITUCCI UGGERI S. 1988: Evidenze tecniche della produzione ceramica a Spia in età ellenistica, in Proceedings of the 3rdSymposium on Ancient Greek and RelatedPottery (Atti Copenhagen, August 31-September 4), pp. 624-632.

PATRONCINI L.1970: Rinvenimenti di materiale preistorico a San Bartolomeo-Case Bigi, in Quaderni di Archeologia Reggiana, pp. 88-89.

PEASE M.Z. 1937: A well of the late fifth Century at Corinth, in Hesperia 6, p. 257-316.

PREKA K., Alexandri1992: A Ceramic Workshop in Figareto, Corfù, in Les Ateliers de potiersdans le monde grec aux époques géométrique, archaique et classique, in BCH, pp.41-52.

ROBINSON D.M. 1929-1950: Excavations at Olynthus, XIII. Vases found in 1934 and 1938, Baltimore, Johns Hopkins Press (London: Oxfors University Press), pp. XIX + 463.

SALZANI L.2002: Una fornace per la ceramica, in Aspes A., Preistoria Ceronese: contributi ed aggiornamenti, Memorie del Museo Civico di Storia Naturale di Verona, 2° serie, Sezione Scienze dell'Uomo, 5 Verona, p. 178.

SARONIO P.1965: Nuovi scavi nella città etrusca di Misano a Marzabotto, in Studi Etruschi XXXIII, pp. 385-416.

SPARKES B.A., TALCOTT L.1970: The Athenian Agorà, 12. Black and plain pottery of the 6th , 5th and 4th centuries BC, Princeton.

TAGLIONI C.1997: Le fornaci del sepolcreto San Vitale di Bologna, inOCNUSS 5, Bologna, pp. 207-224.

Von Eles Masi P. 1982: La Romagna tra VI e IV secolo a.C. La necropoli di Montericcio e la protostoria romagnola, Catalogo della Mostra (Imola 1981), Bologna.

ZAMBONI L.2003-2004: Un insediamento produttivo nell'abitato etrusco-arcaico di Baggiovara di Modena, Relatore C. Chiaramonte Trerè, Tesi di Laurea, Università degli Studi di Milano.