The content is published under Creative Commons Attribution 4.0 International license.

Themed Collections:

Metalworking

Archaeological experiments have been executed over time with many metals used in the past by mankind. Luckily many archaeological objects remain, containing details of their production, use, repair, and discard. In the articles here, you will find mention of copper, bronze, iron, silver, gold and many other metals which have been so important over centuries all around the world.

In this collection of articles, metalworking is mainly about experimentation, based on archaeological sources. Here you will find examples of recreation of processes of metal extraction form their sources, like from rocks, often with the use of fire, but metalworking also includes shaping metal objects, like forging or casting. Our authors discuss the tools used, the processes applied, and the products made, or repaired. What is also in focus are the metalworkers and their position in society.

Featured

Event Review: Bronze Casting in Daugailiai, Lithuania

The Production of Roman Metal Screw Threads - Extended Version

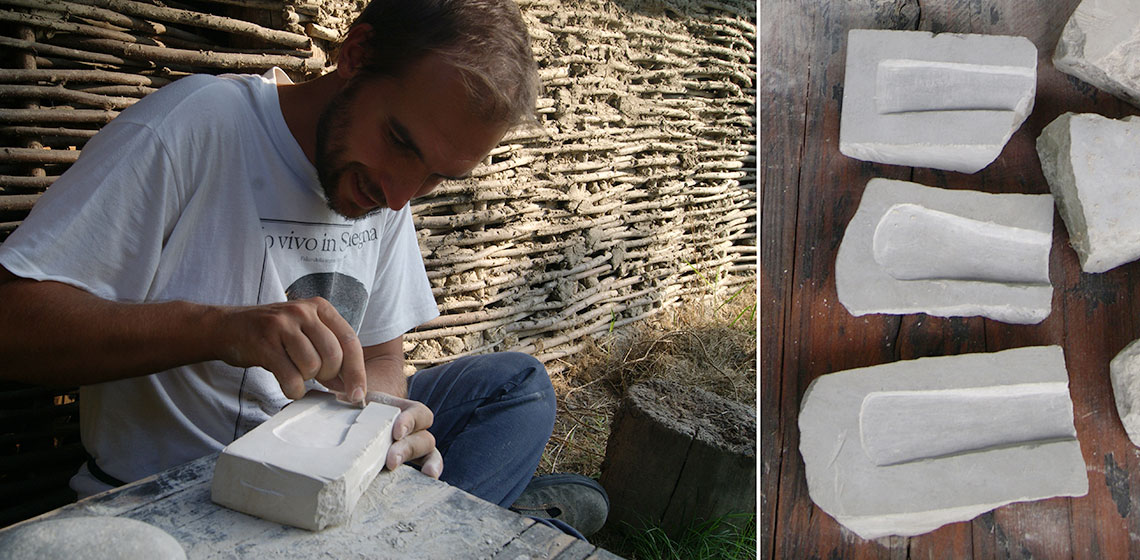

Casting a Copper Age Axe Using a Replica of the Marl Mould Found in Baffoni Cave (AN)

These three artefacts suggested that some kind of metal working had most probably been carried out in the cave: Radmilli first described the mould as “a clay mould for casting… containing a piece of copper” (Radmilli, 1956, pp.

Drawing Wire

Scandinavian Arrowheads of the Viking Age, Their Manufacture and Distribution

The Production of Roman Metal Screw Threads

An Experimental Approach to Ancient Egyptian Metalworking: The Mysteries of the Sesheshet

(Re)constructing an Early Medieval Irish Ard

Evaluation of Mail Horse-Armour

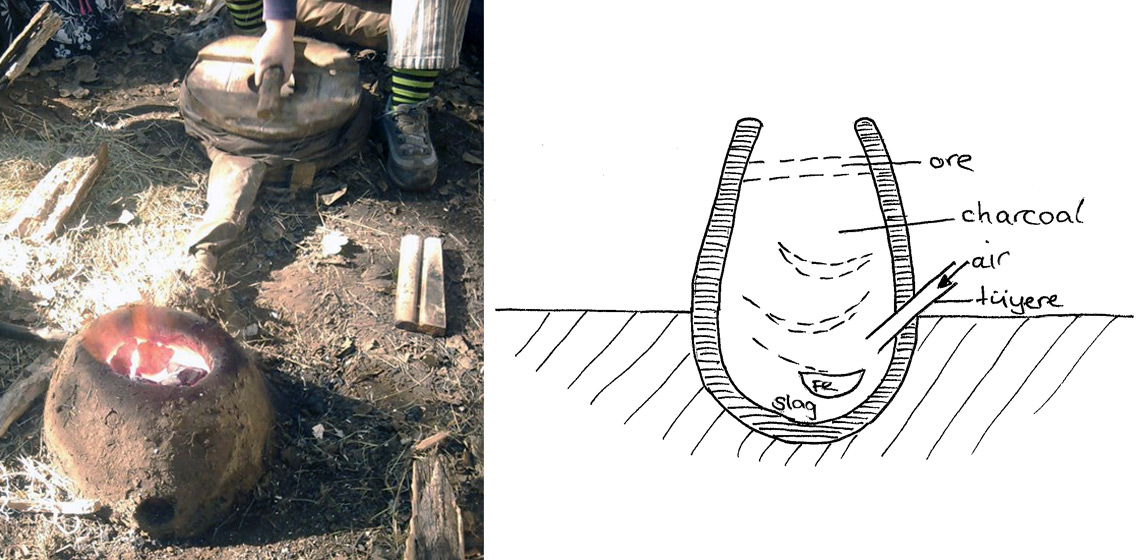

The Little Bowl That Could! Experimental Iron Smelting in a Bowl Furnace

Copper Smelting Could Have Been Discovered in Connection with the Massive Production of Lime Plaster in the Near East During the Pre-Pottery Neolithic B, which is Much Earlier than Previously Believed

A Proposed New Appearance of the Iron Stand from Sutton Hoo, Based on Existing Material

Shedding New Light on the Pure Copper Metallurgy of the Chalcolithic Southern Levant Through an Archaeological Experiment

Roman Gold Washing as Described by Pliny the Elder

***As part of a four-year interdisciplinary research project of a Roman gold mine in the landscape known as the "Karth" to the south of Vienna, Austria, a reconstruction of gold washing took place as described by Pliny the Elder in book 33 of his Natural History. So far, the "Karth" is the only proven Roman gold mine known in the Eastern Alps...

Pyrgos Mavroraki Smelting and Melting Experiments in a Metallurgical Workshop of the Second Millennium BC

Killing the Cauldron: Experimental Research on Dented Bronze Cauldrons from the (post)Medieval Period

Experimental Roman Minting: Casting Silver-Copper Alloys into a Bronze Mould

***This paper provides the details of a Roman minting experiment, which used a bronze mould to cast debased silver blanks typical of the third century A.D. The investigation follows the paper ''Experiments reproducing Roman debased alloys" (George, 2020) which studied the manufacturing methods used...

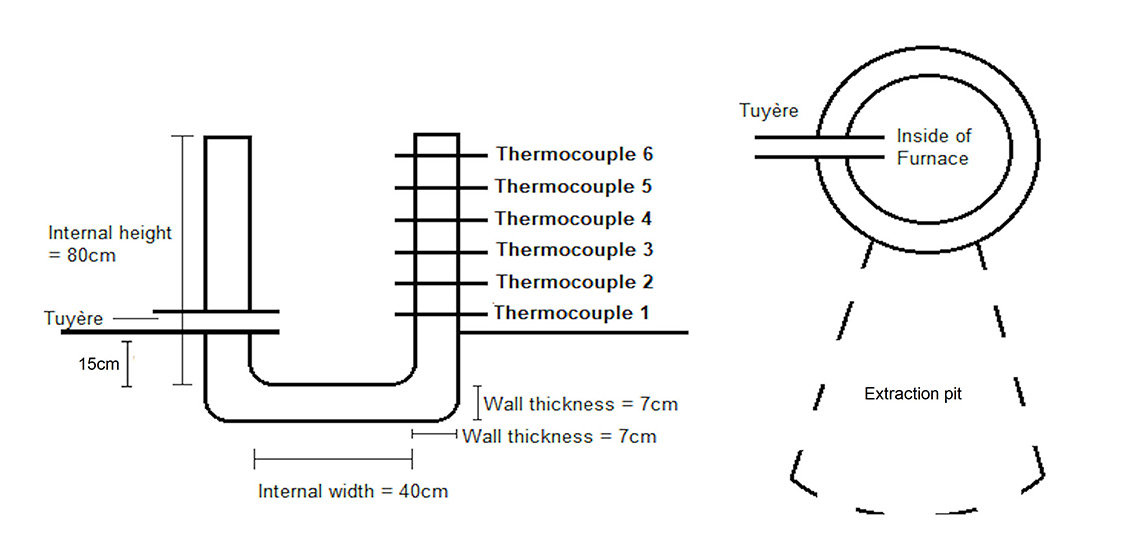

Standardized Reporting of Experimental Iron Smelting - A modest (?) Proposal

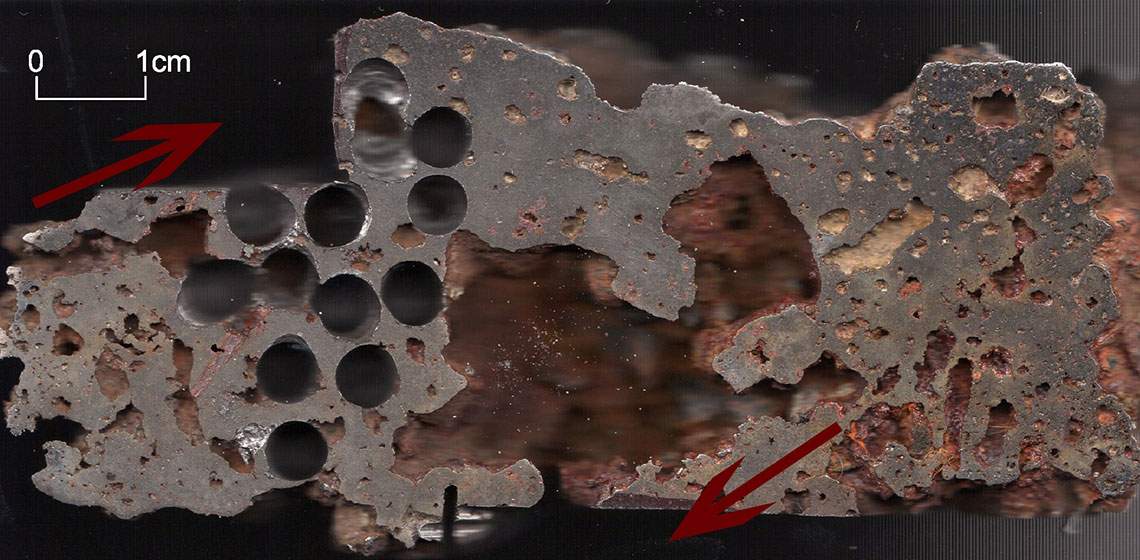

Irish Copper Axe-Ingots Recovered in Brittany: Experimental Casting to Recreate Porous Material

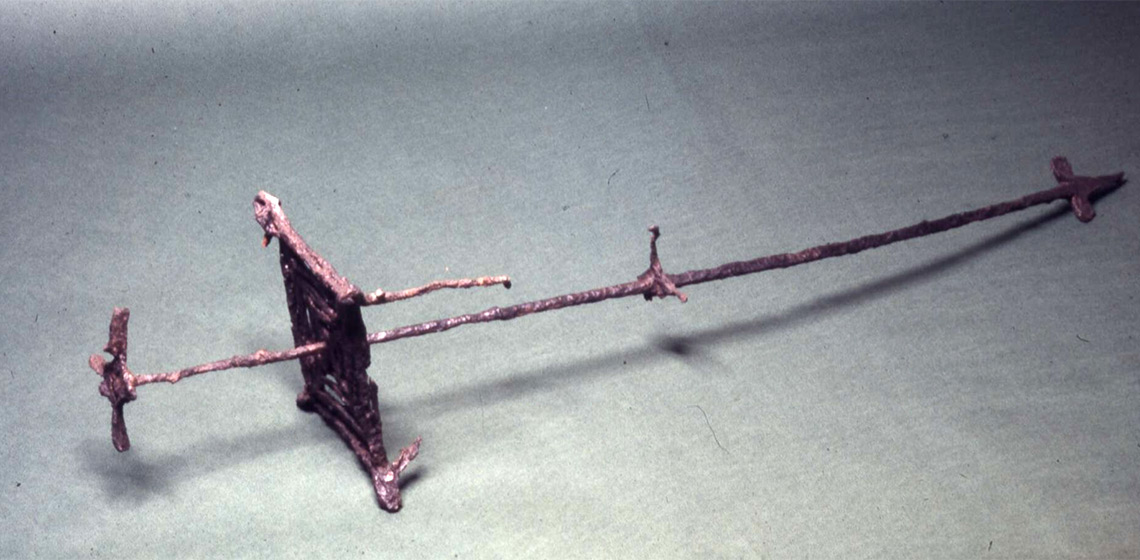

Smelting Conditions and Smelting Products: Experimental Insights into the Development of Iron Bloomery Furnaces

Socketed Axes of the Irish Late Bronze Age: Understanding the Internal Rib Phenomenon

“A Mirror for Men” – Reconstructing a Medieval Polishing Bench and Putting it to the Test

***In the late 5th century AD, the famous Ostrogoth Theoderic the Great received a truly regal gift from the king of the Warini: he was given highly elaborated swords, richly decorated and able to cut through armour. Their fullers (long grooves along the flat side of the blade to reduce weight and to gain stability...

Replica of the Knife 2165 found in Flixborough a Late Anglo-Saxon Period Knife with an Inlay of Twisted Bronze and Silver Wires

Experimental Analysis of Metal Points from Quattro Macine: Reproduction and Interpretation

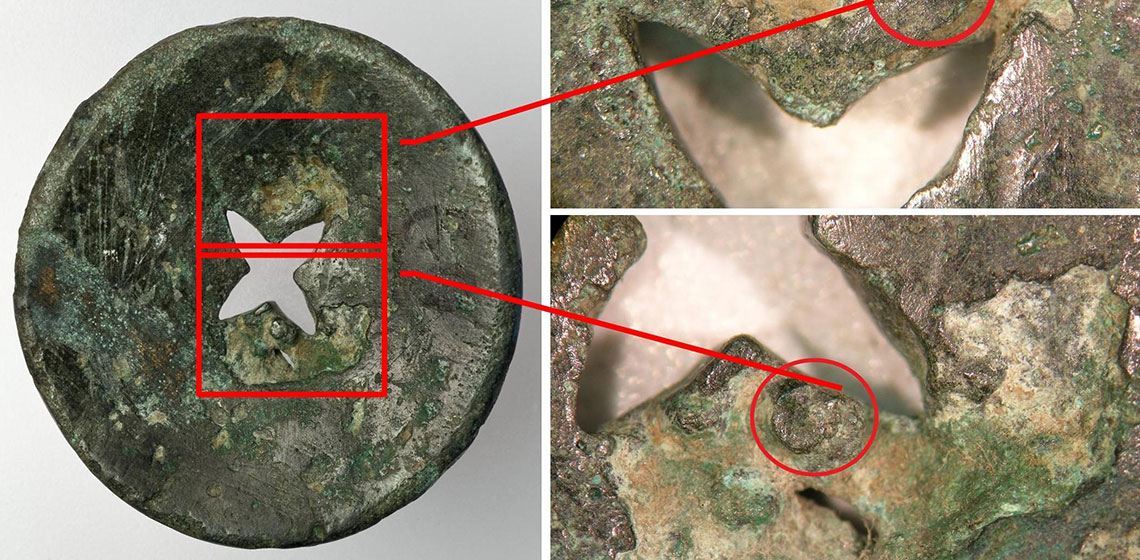

Celtic Copper Alloy Coin Minting Technology: Experiential Approaches

Viking Jewellery Mould Making. Experimental and Reconstructive Aspects

A Seventh Century BC Picenian Cloack Clasp Made of Iron, Bone, Bronze and Amber: Reconstruction of a Masterpiece

Experimental Archaeometallurgy of Early-Middle Bronze Age Cyprus: Pilot Experiments of Copper Smelting at Pyrgos-Mavroraki

***Pyrgos-Mavroraki, an early 2nd millennium BC proto-industrial settlement, is an excellent case-study on which to apply experimental archaeometallurgy because it presents many different elements connected to the chaine-operatoire of copper metallurgy, typical of Early/Middle Bronze Age Cyprus. The site excavated by the Italian Archaeological Mission of the ITABC-CNR of Rome...

Learning to Recreate, Recreating to Learn. Experimental Archaeology

***This paper aims to present and discuss ongoing activities that combine Experimental Archaeology and Ethnoarchaeology developed in the scope of a master's degree, a post-doctoral and other research projects at the University of Vigo (Galicia, Spain), in collaboration with regional open-air museums and educational centres...

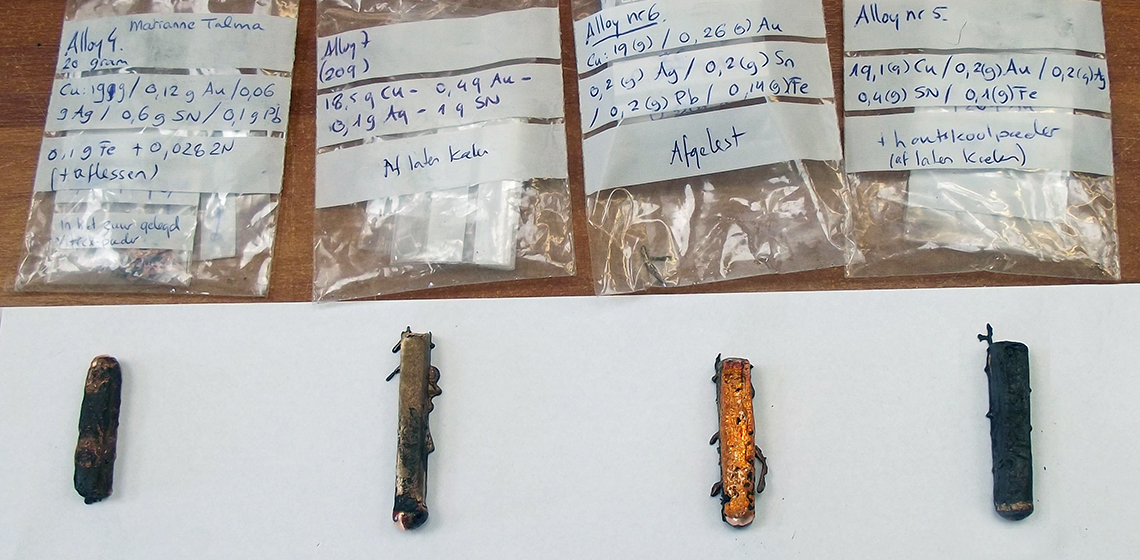

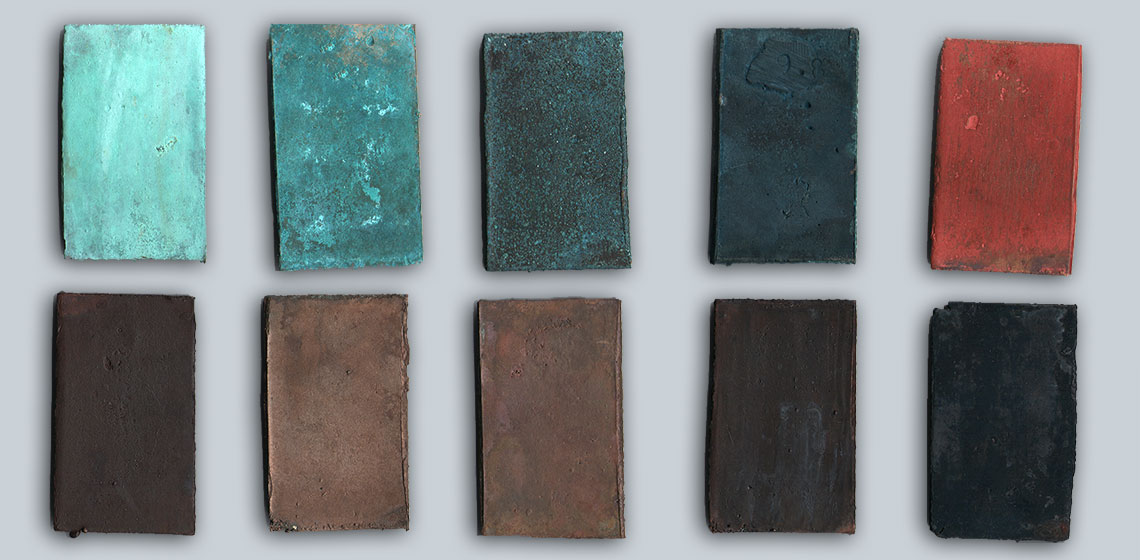

An Experimental Diachronic Exploration of Patination Methodology of Dark Patinated (Arsenical) Copper Alloys on Case Studies from the Eastern Mediterranean Bronze Age and Early Iron Age

***Artificially patinated copper alloys are found archaeologically in polychrome artefacts from the 19th century BC Egypt to historical and contemporary Japan. The unusual colour variations observed in these patinas, ranging from black to blue to purple, is due to a minor amount of gold (Au) and silver (Ag) in their copper matrix, whereas accompanying elements such as tin (Sn), iron (Fe), and arsenic (As) might influence workability, hue or shine.

Now we’re Cooking with Gas! How Experimental Archaeology Challenges Modern Assumptions about Metal Recycling

Reconstruction of the Ancient Greek Long Jump - an Opportunity for Multidisciplinary Collaboration

The Colour Palette of Antique Bronzes: An Experimental Archaeology Project

Spiral Tube Decorations: a Thousand Years of Tradition

Getting Hammered: The Use of Experimental Archaeology to Interpret Wear on Late Bronze Age Hammers and Modern replicas

Experiencing Visible and Invisible Metal Casting Techniques in Bronze Age Italy

***What we know about Bronze Age metalworking in Italy basically relies on finished artefacts and on stone, clay or bronze implements involved in the process of manufacturing (tuyères, crucibles, moulds, hammers, chisels, et cetera; Bianchi, 2010; Bianchi, in press).

Investigating the Influence of the Kettle Material on Dyeing in the Industry of Pompeii

***Dyeing, especially in bright, intense colours, has been one of the methods used to embellish textiles and add to their value. A considerable dyeing industry can be shown to have existed in Pompeii. The city of Pompeii was destroyed in a volcanic eruption in AD 79, but its remains were preserved in situ...

From the Soil to the Iron Product - the Technology of Medieval Iron Smelting

***Nowadays, the development of technology rushes past the people of the machine-based technical civilisation, therefore they fail to understand the technological wonders that surround them. One of these is the ancient technology of iron smelting...

To Use or Not to Use a Minoan Chisel? Ancient Technology in a New Light

***The Minoan chisel is thought to have been used by the metal worker, the stone mason, the sculptor, the carpenter, and the ivory and bone worker. However, barely any work has been conducted to substantiate the different workers and their chisels...

Observations on Italian Bronze Age Sword Production: The Archaeological Record and Experimental Archaeology

***In spite of the very large quantity of Bronze Age swords in Northern Italy, only a few stone moulds have been found. Tests have shown that carving such big stone moulds (more than 60 cm long) requires a large amount of raw material, deep knowledge and skill, rather than a wide set of implements...

From Wax to Metal: An Experimental Approach to the Chaîne Opératoire of the Bronze Disk from Urdiñeira

***The so-called ‘Treasure of A Urdiñeira‘ (A Gudiña, south-east of the province of Ourense, Spain) consists of an assemblage of three metal artefacts: two gold bracelets and a bronze button or disk, dated from the transition between the Late Bronze Age and the Early Iron Age...

Copper + Tin + People: Public Co-Smelting Experimentation in Northwestern Iberia

***In the present paper an experiment made in north-western Iberia for producing bronze using local ores and similar techniques to those perhaps practiced by the ancient prehistoric metallurgists during Bronze Age is described...

A Picenian Warrior Who Lived in the Eight Century BC: A Hypothetical Reconstruction

Various populations inhabited this territory from the tenth to the early third century BC, when the Roman army took control of it: the Laziali and Sabini in Lazio, the Etruscans and, from the fifth century, Celts in Toscana and Emilia Romagna, Umbri in Umbria and Picenians in Marche and Abruzzo. At the beginning of the Iron Age, and until the eighth century, we have evidence of other populations as well. The most ancient group being the Sub-Apenninical culture, which were Villanova and Proto-Villanovan populations that seem to have had towns in the Region Marche.

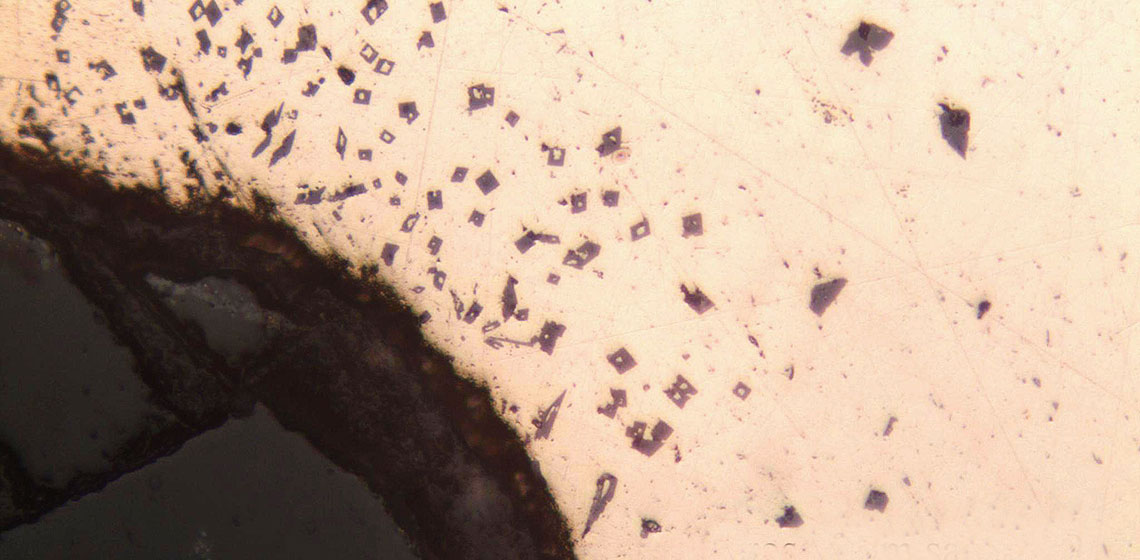

The Production of High Carbon Steel Directly in Bloomery Process: Theoretical Bases and Metallographic Analyses of the Experiments Results

***The series of experiment on iron smelting conducted by author in 2012 resulted in very good quality high carbon steel produced directly in the bloomery furnace. Bearing in mind the unusual mechanism of carburization in a 'Aristotle furnace', a question arose concerning possibility of occurrence the same phenomenon during the smelting process. This paper discusses the results of the metallographic studies of produced iron as well as the description of the conducted experiments.

The Quality of the Craft

Scandinavian Iron Age and Early Medieval Ceramic Moulds - Lost Wax or Not or Both?

***Since the 1940s we have had a discussion in Scandinavia concerning ancient mould-making methods. The question of different methods in the production of ceramic moulds has taken a large part in these discussions; by lost wax or by direct matrix-methods...

How Metallographic Examinations Can Give the Forming Process of Metal Artefacts? The Example of the Hoard of Farébersviller

***The hoard of Farébersviller (Moselle, France) was discovered in 1991 during rescue excavations (See Image above). This set contains 130 "bronze" artifacts, which date to the Late Bronze Age (8th century BC)...

Historical Techniques: Cold Gilding

***An historal technique of goldplating, described in 18th century literature, was reproduced. This cold-plating technique uses salts of gold, produced by dissolving gold in aqua regia. these salts are then rubbed onto a silver surfaces...

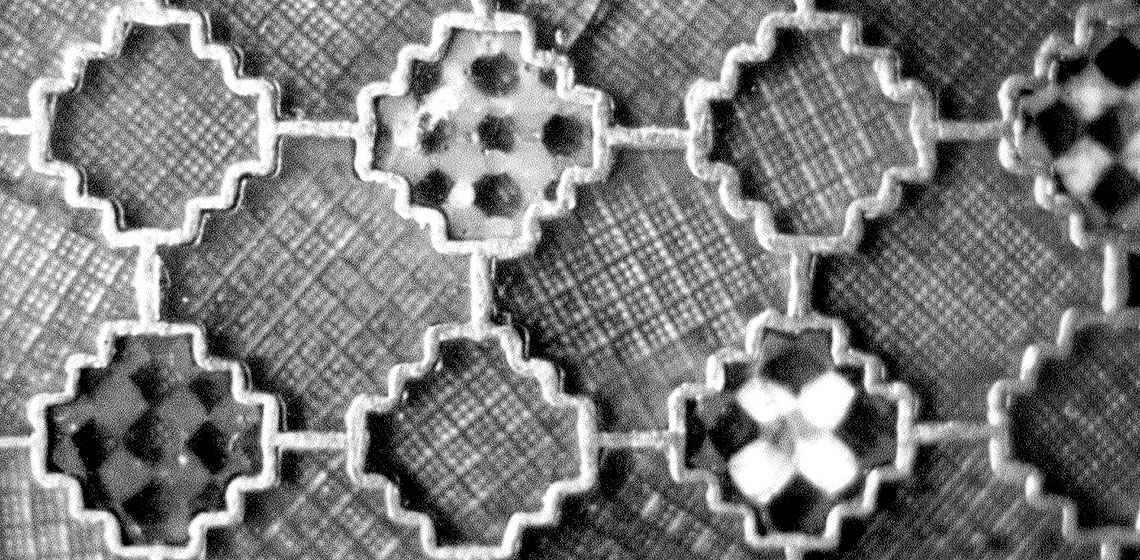

Precision Lost Wax Casting

***The limits of precision casting were explored experimentally at the Bronze Casting Workshop at Wilhelminaoord, the Netherlands, by making wax models, moulds and lost wax castings using essentially early metalworking conditions. Geometrically patterned models of Dark Age type dies were used to...

The Experimental Reconstruction in Bronze of a Merovingian Treasure Box from Sixth Century A.D.

***Considerations about a lost ancient fabrication technique of bronze attachements from a merowingian treasure box pointed out that practical experiments had to be done to reconstruct the cast and coldwork. A self made oven and mould sould help to...

From the Object to the Mould: Is there a Connection between Microstructure of a Cast Bronze Object and its Mould Material Used?

***The question studied within the framework of the Wilhelminaoord Workshop was: In which way the mould material does influence the cast structure of a bronze object? For this, casts in two different mould materials...

Producing Silver Sheet According to Cellini

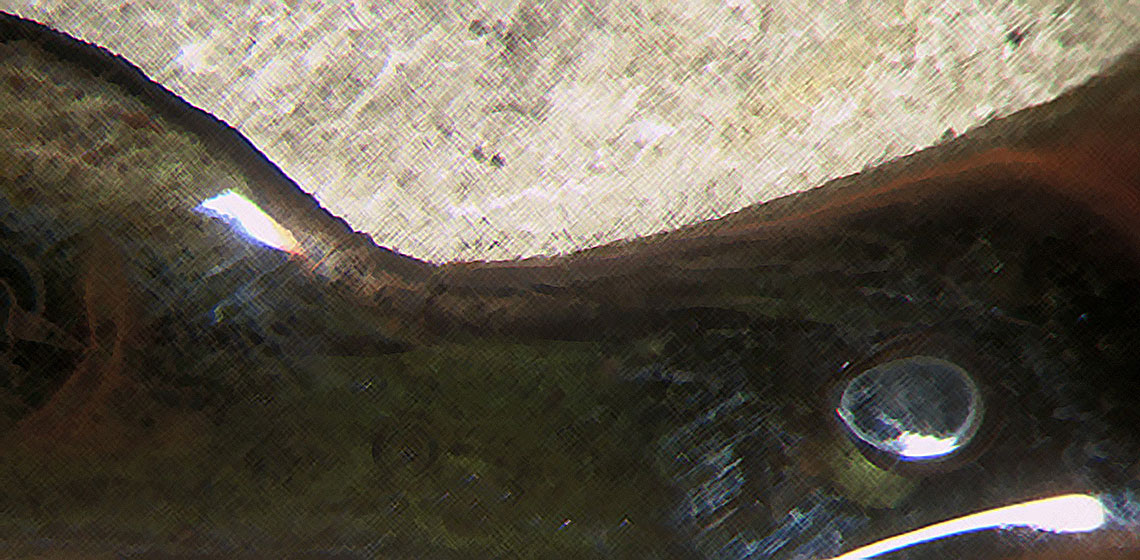

***During a short internship in The Hagues Municipal Museum, I noticed some blisters in a seventeenth century V.O.C.-dish. I thought they were gas bubbles which might have been introduced in the material during coagulation. When hammering to sheet the bubbles would take the shape of blisters which would turn visible during annealing. Why, however, were these shapes not visible on many other pieces?

Ancient Repairs on Bronze Objects

***Bronze objects can be damaged in many ways, for example during casting or during their time of use. Often this damage was repaired using various techniques. In this paper, some examples of ancient repairs and their techniques are described and illustrated with examples published in the literature...

The Use of Metal Moulds to Cast Lead Weights onto the Wooden Shaft of a Plumbata

"But if you don't get any IRON..." Towards an Effective Method for Small Iron Smelting Furnaces

Building and operating a small bloomery iron furnace is certainly a wonderful public demonstration for any museum or living history site. It is however a complex technical process, with many individual factors combining for success. Over the last decade in North America, small teams of blacksmiths have developed predictable working methods through trial and much error. This direct practical experience can provide some insights into questions that even the best researched theories may not be able to solve.

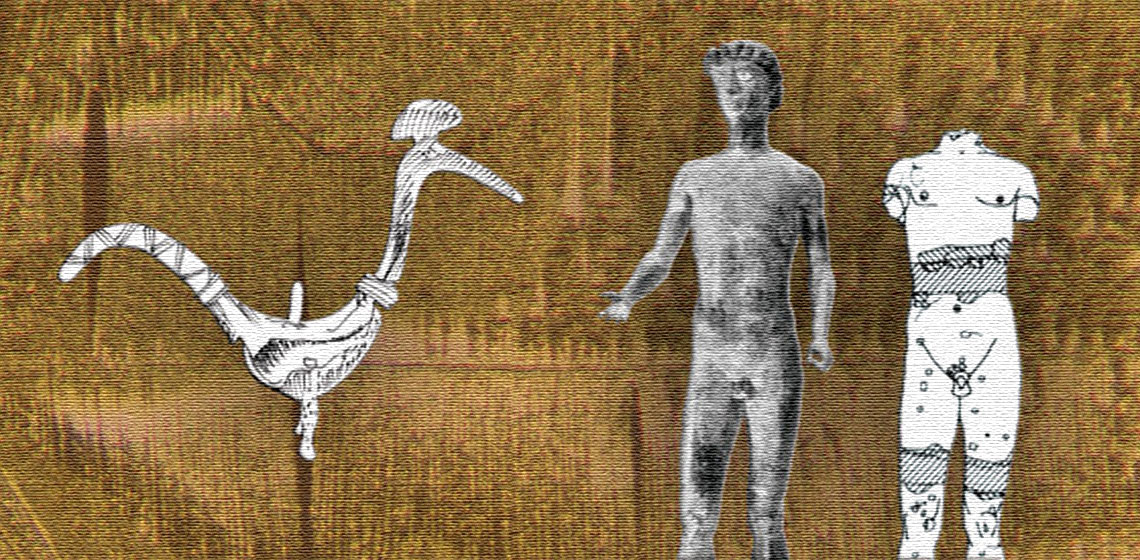

Anatomy of Prehispanic Bells - Study of an Ancient Lost Process

The elaboration of bells in the Prehispanic Era was of great importance due to the special meaning attributed to them in religious ceremonies. Today, knowledge of the techniques that were used in their fabrication is scant and lacking in detail. For that reason, the objective of the present study was to carry out a morphological study of bells from western Mexico...